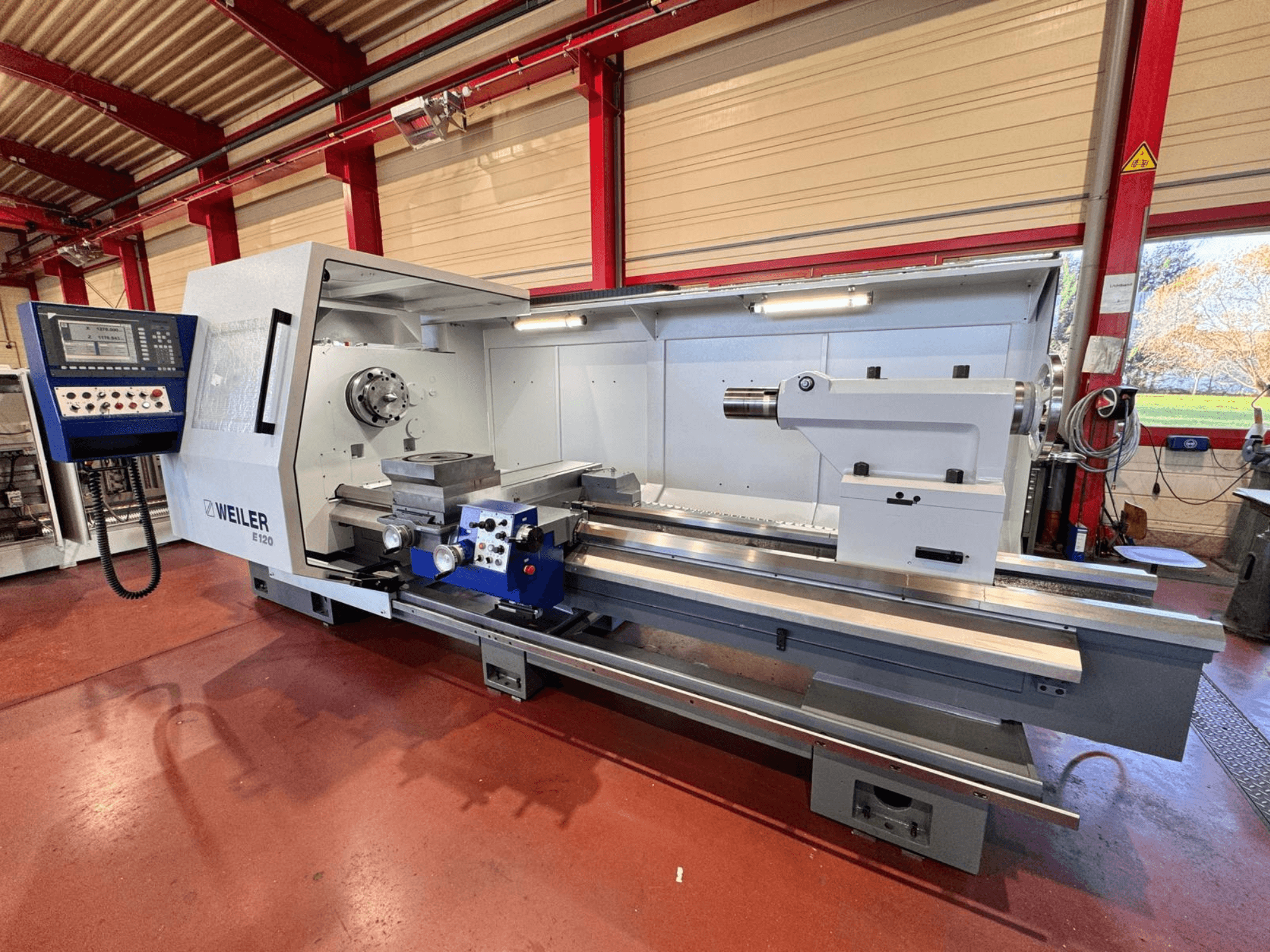

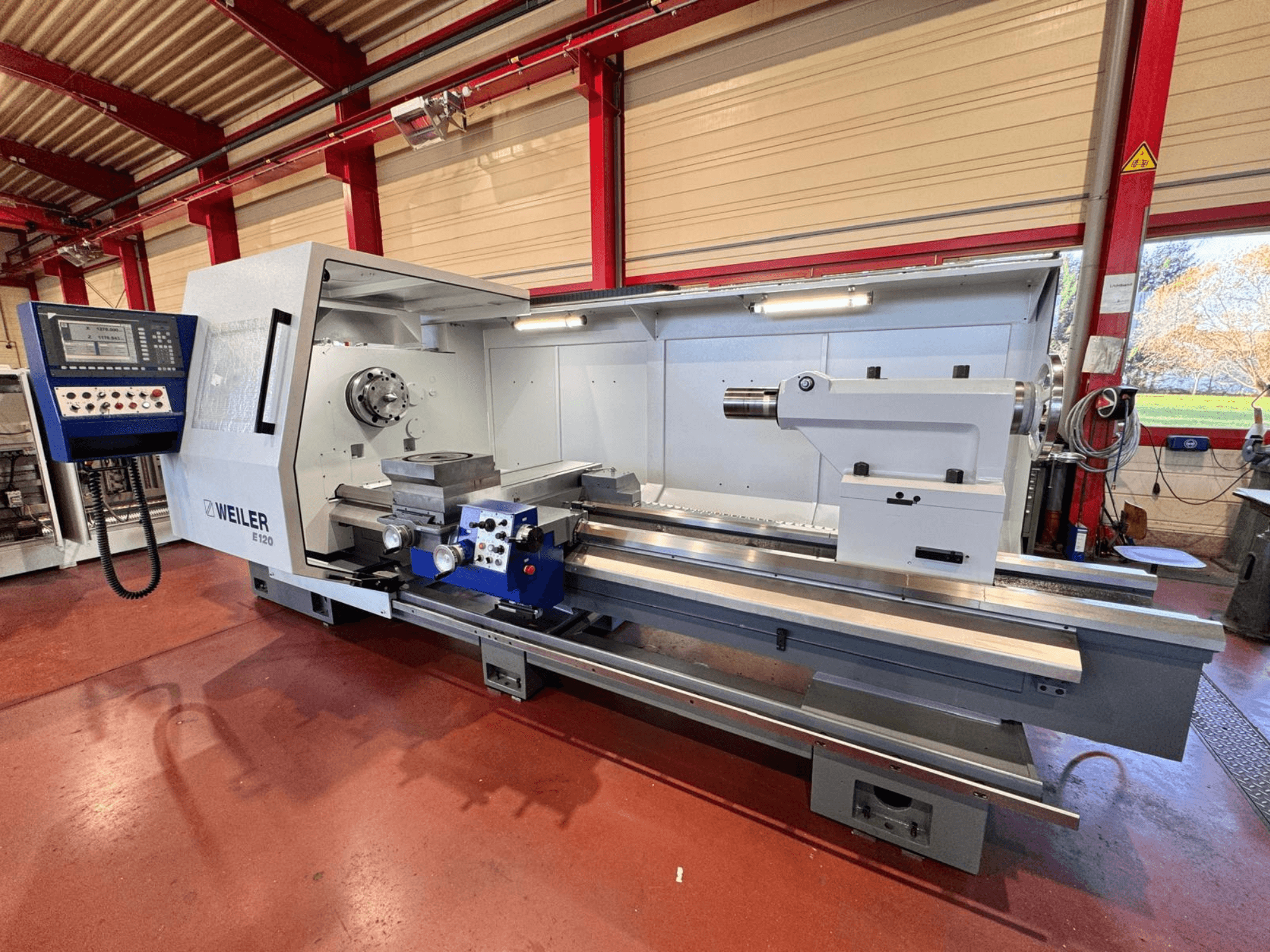

Weiler - E120x3000DE-TUR-WEI-2001-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Weiler E120x3000 For Sale | gindumac.com

This Weiler E120x3000 was manufactured in 2001. It features a center distance of 3000 mm, center height of 600 mm, and a swing diameter over bed of 1200 mm. The spindle bore is 165 mm, and it offers a robust main drive with a power of 45/37 kW. Ideal for heavy-duty turning, this machine includes accessories like a lathe chuck, faceplate, and a steady rest. Contact us for more information about this machine.

Overview

- brand: Weiler

- year: 2001

- MODEL: E120x3000

- application type: Turning

- Location: Germany

- machine type: Horizontal Turning Machine

- control unit brand: SIEMENS

Technical Information - Weiler E120x3000

Control Unit

- Control Brand: SIEMENS

- Control Model: 810 D

Dimensions

- Machine Height: 2120 mm

- Machine Length: 5400 mm

- Machine Weight: 11500 kg

Movement

- Number of Axes: 2

Technical Specification

- Spindle Power: 45 kW

Additional Information

Working area:

Center distance: 3000 mm

Center height: 600 mm

Swing diameter over bed: 1200 mm

Swing diameter over cross slide: 830 mm

Cross slide travel: 590 mm

Bed slide guide length: 860 mm

Turning tool cross-section (H x W): 40 x 40 mm

Tool holder: Parat size 4

Turning spindle:

Spindle head DIN 55027 / 55026, size 15

Spindle bore: 165 mm

Main spindle taper: metric 171

Main drive:

Drive power (60% / 100% ED): 45 / 37 kW

Max. spindle torque: 8000 Nm

Speed range gear stage 1: 1–280 rpm

Speed range gear stage 2: 4–900 rpm

Tailstock:

Quill diameter: 140 mm

Quill stroke: 300 mm

Quill internal taper: MK 6

Machine dimensions and weight:

Overall length: 5400 mm (without chip conveyor), 6535 mm (with chip conveyor)

Overall width: 2600 mm

Overall height: 2120 mm

Machine weight: 11,500 kg

Overhaul services:

Hardening and grinding of all bed guides

Grinding of tailstock guides

Overhaul of the complete bed and cross slide assembly (grinding/scraping all guideways)

Renewal of the bed slide's sliding lining

Renewal or relining of the keyways and bottom guides

Renewal of all wipers

Replacement of all belts

Overhaul of the main spindle assembly in the headstock

Renewal of the X-axis including bearings

Renewal of the Z-axis including bearings

Overhaul of the tailstock quill (MK 6 taper regrinding), replacement of spindle and nut

Adjustment of the tooling system

Replacement of the main spindle motor

Checking of the auxiliary motors (X- and Z-axis)

Overhaul of existing safety devices (sliding hood/jaw guard)

Replacement of all rotary, toggle, and limit switches

Replacement of the spindle and handwheel encoder

Replacement of the movable cables and coolant hoses in the work area

Replacement of the central lubrication unit

Renewal of the energy chains

Painting according to specifications (standard textured basalt and light gray)

Assembly and geometric inspection of the machine according to DIN 8605

Additional equipment

1x used lathe chuck Ø630 mm with various jaws

1x used faceplate Ø1100

1x used steady rest, max. Ø300

1x used chip conveyor

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing