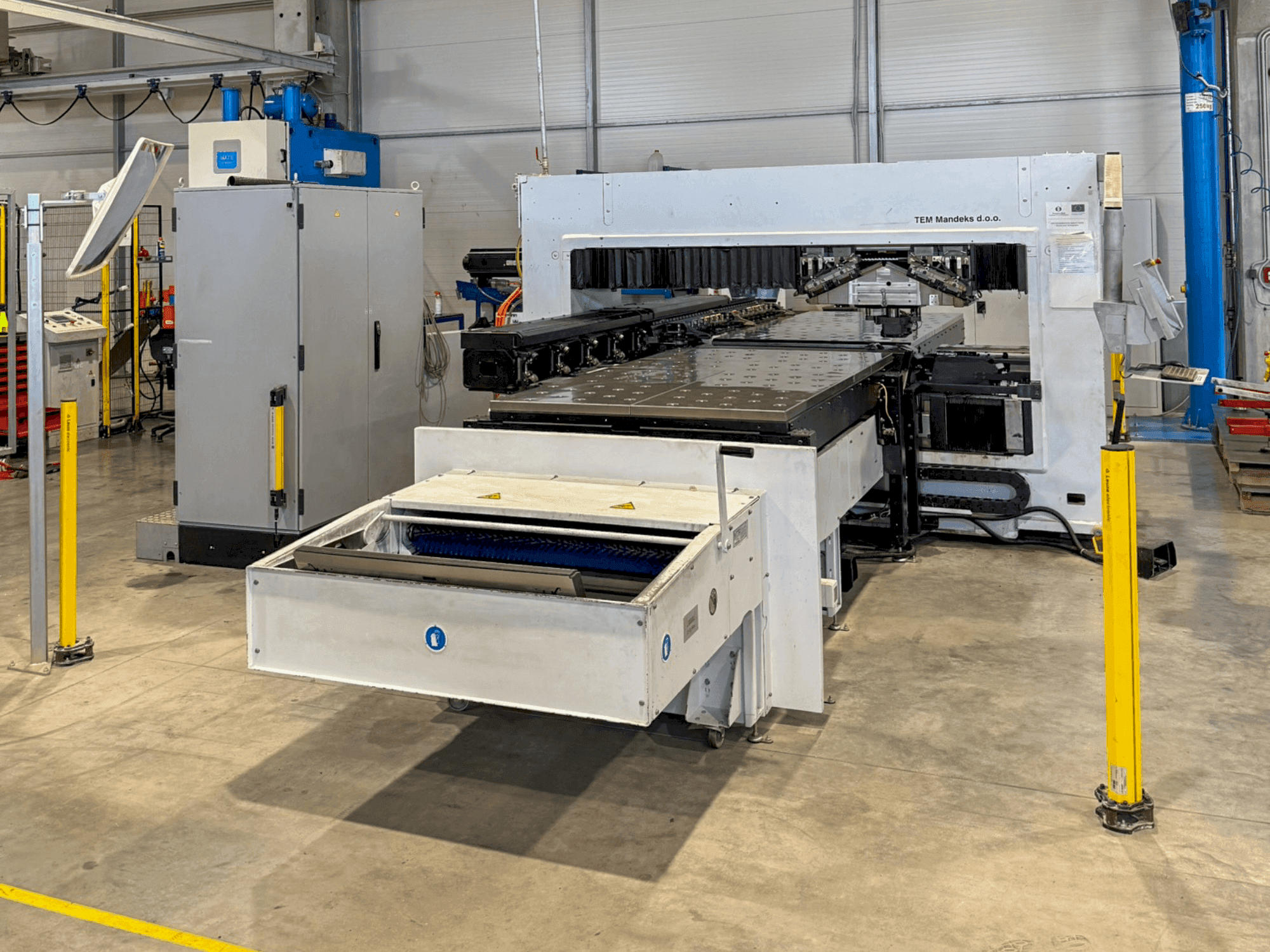

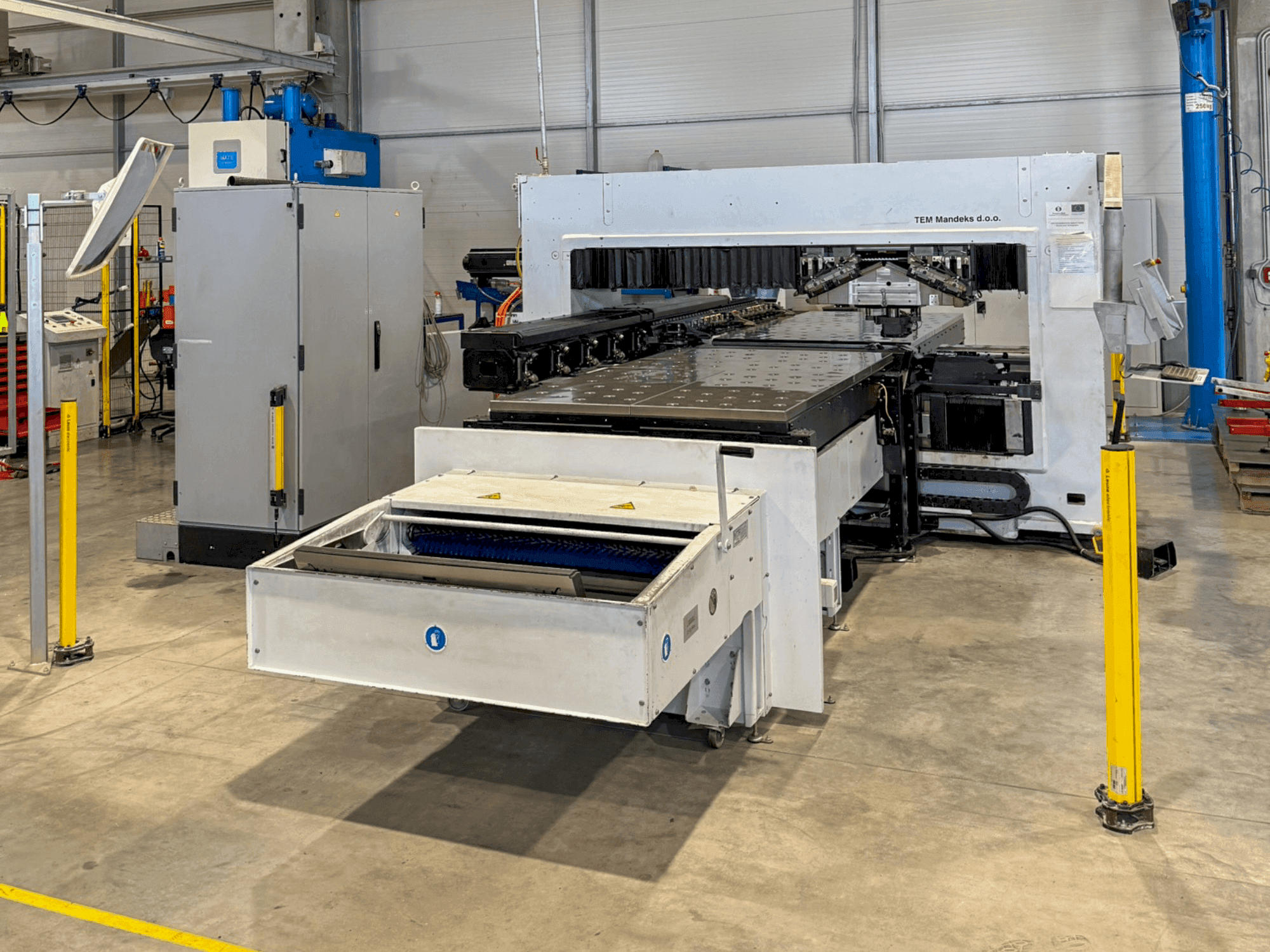

TRUMPF - TruPunch 1000 (S19)BA-PUN-TRU-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Sheet Metal Machinery

- ➤ Used TRUMPF TruPunch 1000 (S19) For Sale | gindumac.com

This TRUMPF TruPunch 1000 (S19) was manufactured in 2018. It features a closed machine frame, hybrid axis system, and a linear magazine with 20 spots for clamps and tools. Equipped with maintenance-free 3-phase servo motors and a TRUMPF control based on Bosch Rexroth IndraMotion MTX, it offers advanced punching capabilities and efficient operation with only 16,000 work hours. Contact us for more information about this machine.

Overview

- brand: TRUMPF

- year: 2018

- MODEL: TruPunch 1000 (S19)

- production hours: 16000

- application type: Punching

- Location: Bosnia and Herzegovina

- machine type: CNC Punching Machine

Additional Information

Additional equipment

Precision deburring and roller technology

Smart Punch Monitoring

Parts conveyor belt for part removal flap

Advanced punching equipment

Machine Benefits

Technical Machine Benefits

Recently changed all most important parts (guide, pump), with official service documentation

Serviced with official service throughout its usage

Closed machine frame

Hybrid axis system

Repositioning unit with programmable stripper

Part chute right side

Punching head

Delta drive

Programmable position of the presser foot

Forming // stroke rate punch

Extra Information

Control Unit TRUMPF control based on Bosch Rexroth IndraMotion MTX Control panel with 19" TFT touch screen Integrated technology data Interface Teleservice via internet Automatic shutdown mechanism NC program management Production plan Data transfer USB interface and network connection Network connection RJ45 Central Link Main Drive Drives with maintenance-free 3-phase servo motors Tools Linear magazine with 20 spots for clamps and tools Hydraulic clamps (2 pieces) Foot switch for closing clamps Rotatable single tool adapter Tool length compensation Spray lubrication for punches Vacuum slug removal Function MultiTest Function MultiBend Function tapping with thread counter Part removal flap left side Sensor for part removal flap Additional clamp The Laser cutting technology package is retrofittable Ability for retrofitting the PartMaster Advanced standard configuration 1st index pin position right hand inner side Ball-fitted tables Burr removal by Monitoring of level Sheet collision detection Straightener Compact 240 x 1250 mm Tools and specialized crane for manipulation available for extra cost.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing