Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

TRIMILL - VC1110DE-MIL-TRI-2011-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- TRIMILL VC1110 milling machine

This TRIMILL VC1110 milling machine was made in the year 2011 in the Czech Republic. It is operated with a Heidenhain TNC530 control unit. It has approximately 12000 spindle hours. This machine has a spindle speed up to 14000 rpm. This 3 axis machine especially developed for the tool, die and mould industry.

Overview

- brand: TRIMILL

- year: 2011

- MODEL: VC1110

- production hours: 12000

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: HEIDENHAIN

Technical Information - TRIMILL VC1110

General Data

- Measurements width: 4300 mm

- Measurements depth: 3550 mm

- Measurements height: 3810 mm

- Machine weight: 15000 kg

Control Unit

- Model: TNC530

- Brand: HEIDENHAIN

Main drive

- Spindle speed range: 14000 1/MIN

- Spindle motor power: 25 kW

- Number of axis: 3

Movement

- X-AXIS Movement: 1000 mm

- X-AXIS Rapid traverse: 30000 mm/min

- Y-AXIS Movement: 1110 mm

- Y-AXIS Rapid traverse: 30000 mm/min

Table

- Outer length: 1500 mm

- Outer width: 1300 mm

- Table load: 8000 kg

Tools

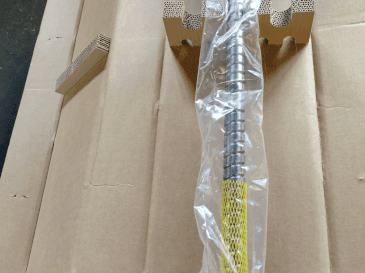

- Type of tool holder: HSK80

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Laser measurement

- 10 compartment changer

- 3-d probe

- Top equipped

Technical Machine Benefits

- Heavy duty 3-axes machine, especially developed for the tool-, die- and mould industry

- Closed design of the double-beam and cross-slide (box in box design) with internal, quadruple guided ram-type milling unit

- Constantly perfect cutting results by means of load- and thermo symmetric design

- Execution as overhead gantry, therefore controlled dynamic and accuracy

- Stationary work piece for constantly good surface qualities

- High productivity by means of roughing and finishing in one set-up

- Very compact machine, large working area in spite of extreme small floor-space

- Customized distance between spindle nose and clamping surface

- Ergonomic operation by means of floor-level access to the machine tool

- Convincing cost-performance ratio

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to TRIMILL VC1110

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

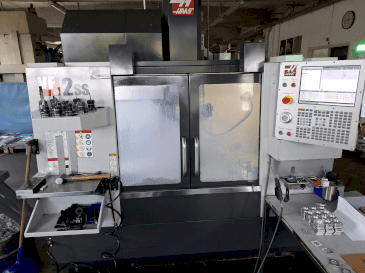

VF 2 SS

HAAS - Vertical Machining Centre

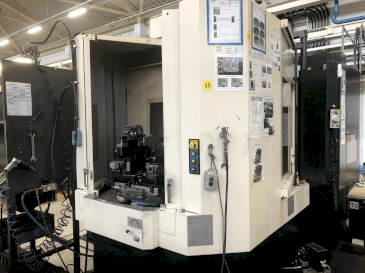

EC-400

HAAS - Horizontal Machining Centre

HM 6300

DOOSAN - Horizontal Machining Centre

A61-5XR

Makino - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

VF-4

HAAS - Vertical Machining Centre

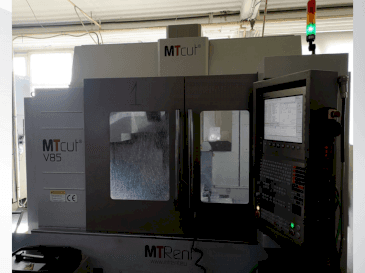

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

VTC-300C

Mazak - Vertical Machining Centre