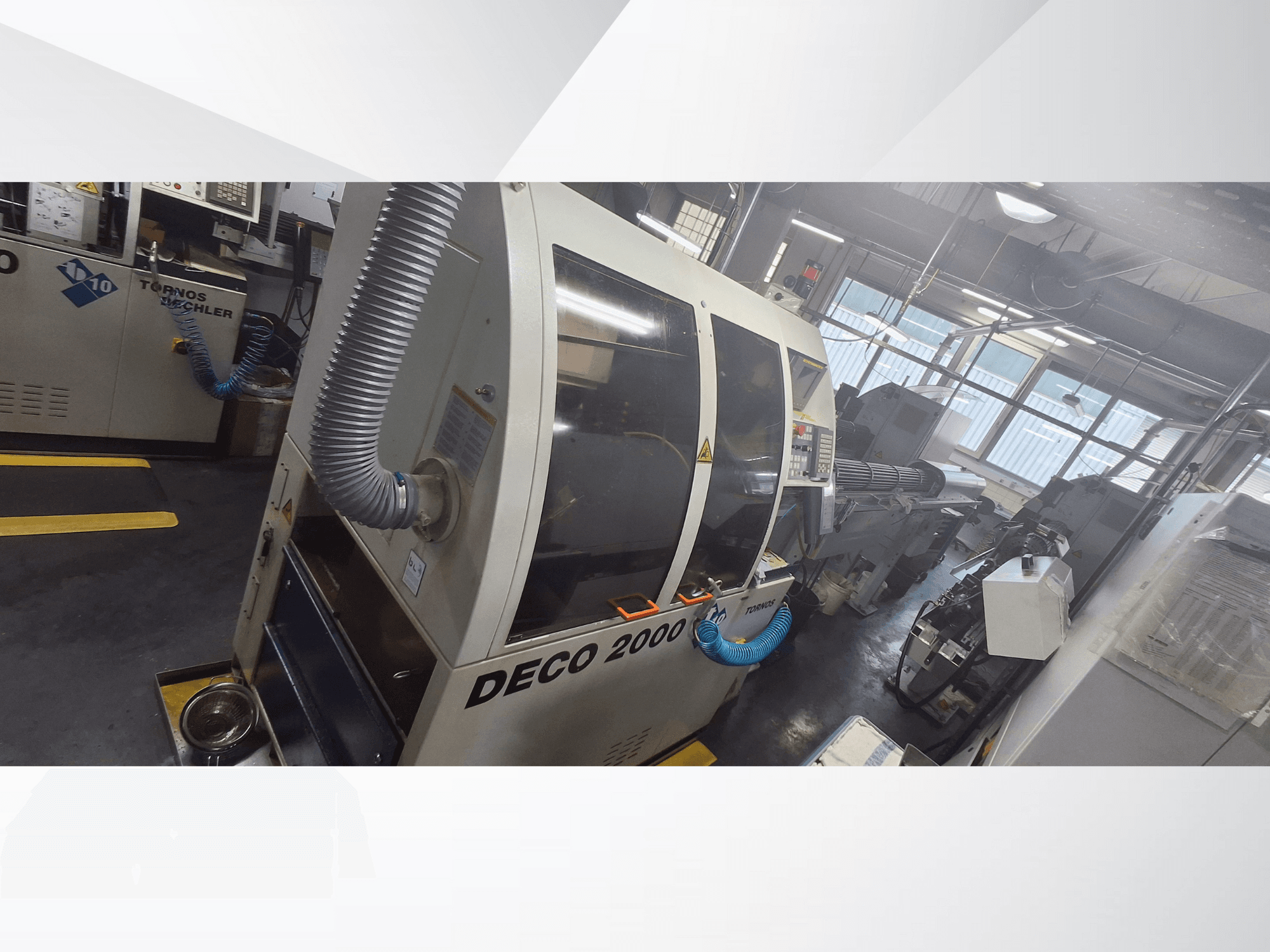

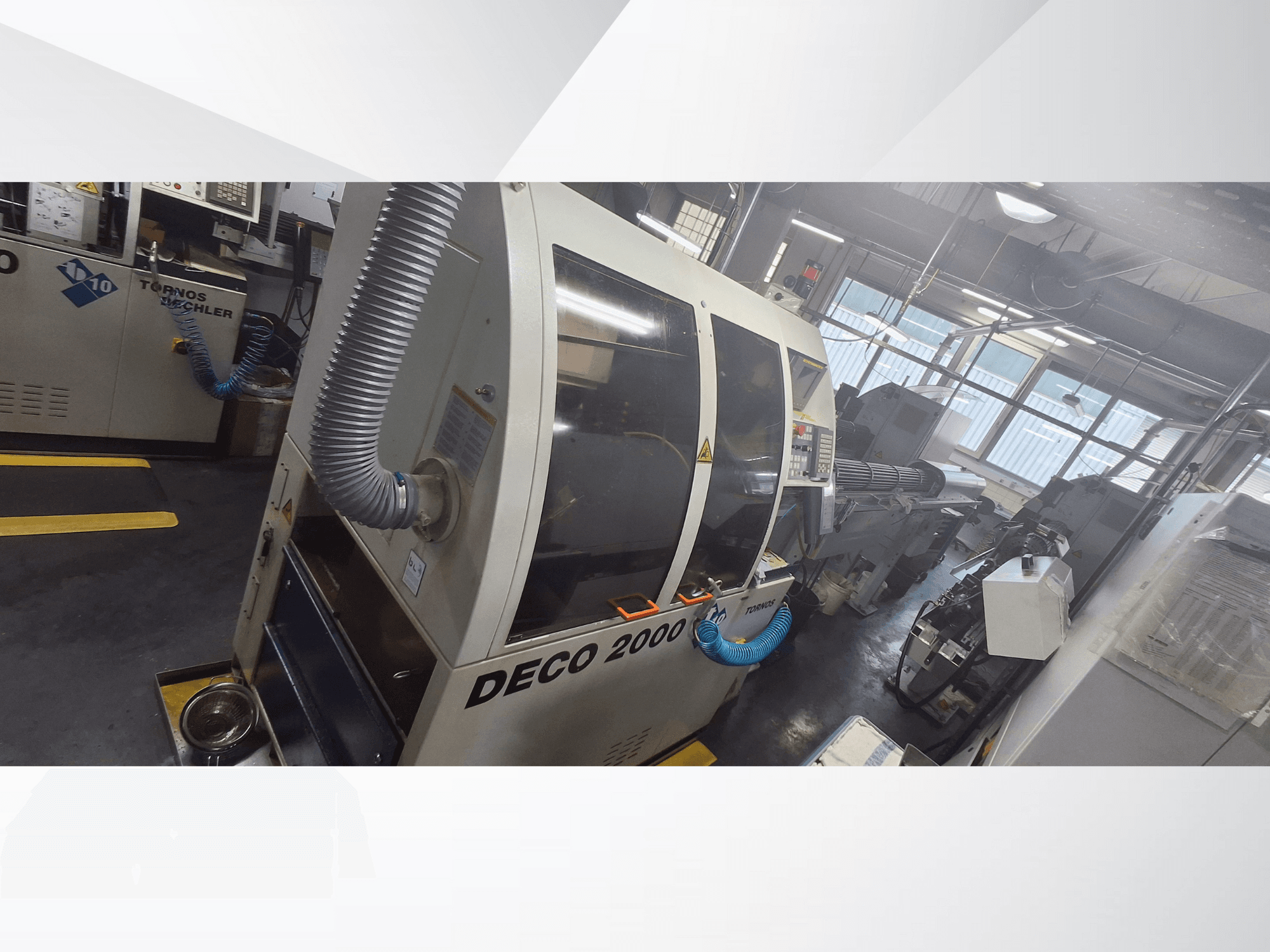

TORNOS - DECO 10aDE-TUR-TOR-2003-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used TORNOS DECO 10a For Sale | gindumac.com

This TORNOS DECO 10a was manufactured in 2003. It features a movable headstock, directional spindle stop, and multiple cross-slides with tool holders for versatile machining. Equipped with a counter-spindle and programming software in five languages, it's ideal for complex turning tasks. Includes interfaces for bar feeders and tool breakage detection. Reach out for more information about this machine.

Overview

- brand: TORNOS

- year: 2003

- MODEL: DECO 10a

- application type: Turning

- Location: Germany

- machine type: Swiss Type Turning Machine

Additional Information

Additional information

TB-DBCO Version 6 programming software: Single-user product, configuration available in 5 languages (French, German, English, Italian, Spanish)

Programming language: ISO programming language

Movable headstock: S1/Z1 axis, n = 16000 rpm, F13 collet chuck

Spindle stop: Directional spindle stop S1 (programming increment 0.1 degrees)

Cross-slides:

1 cross-slide with 4 tool holders (X1 and Y1 axes)

1 cross-slide with 3 tool holders (Z3 and X3 axes)

1 cross-slide with horizontal and vertical movement (Z4 and X4 axes)

Pneumatic cylinders: 3 independent for quick positioning

Counter-spindle: Independent (S4), n = 12000 rpm, F13 collet chuck

Cross Slide Support Options:

Pre-adjustable turning tool holder, long type, 8x8 mm cross-section

Main spindle rotation direction: right

S2 motorization (electric/mechanical) for driven units on the X2-Y2 linear tool carrier

Driven end drilling/milling unit: Max. speed 12000 rpm

Cross drilling/milling/tapping attachment for BSX 12 collet chuck

Sensor: Tool breakage detection with TYPE MIDI-DETECTOR, oscillating probe type MINI-DETECTOR, electrical interface, pneumatic control equipment

Interface: Adapting an LNS bar feeder

Spinde Speed: n = 16000 rpm indicates the machine has a moderate spindle speed capacity.

Optional: Comprehensive package of measuring instruments

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing