Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

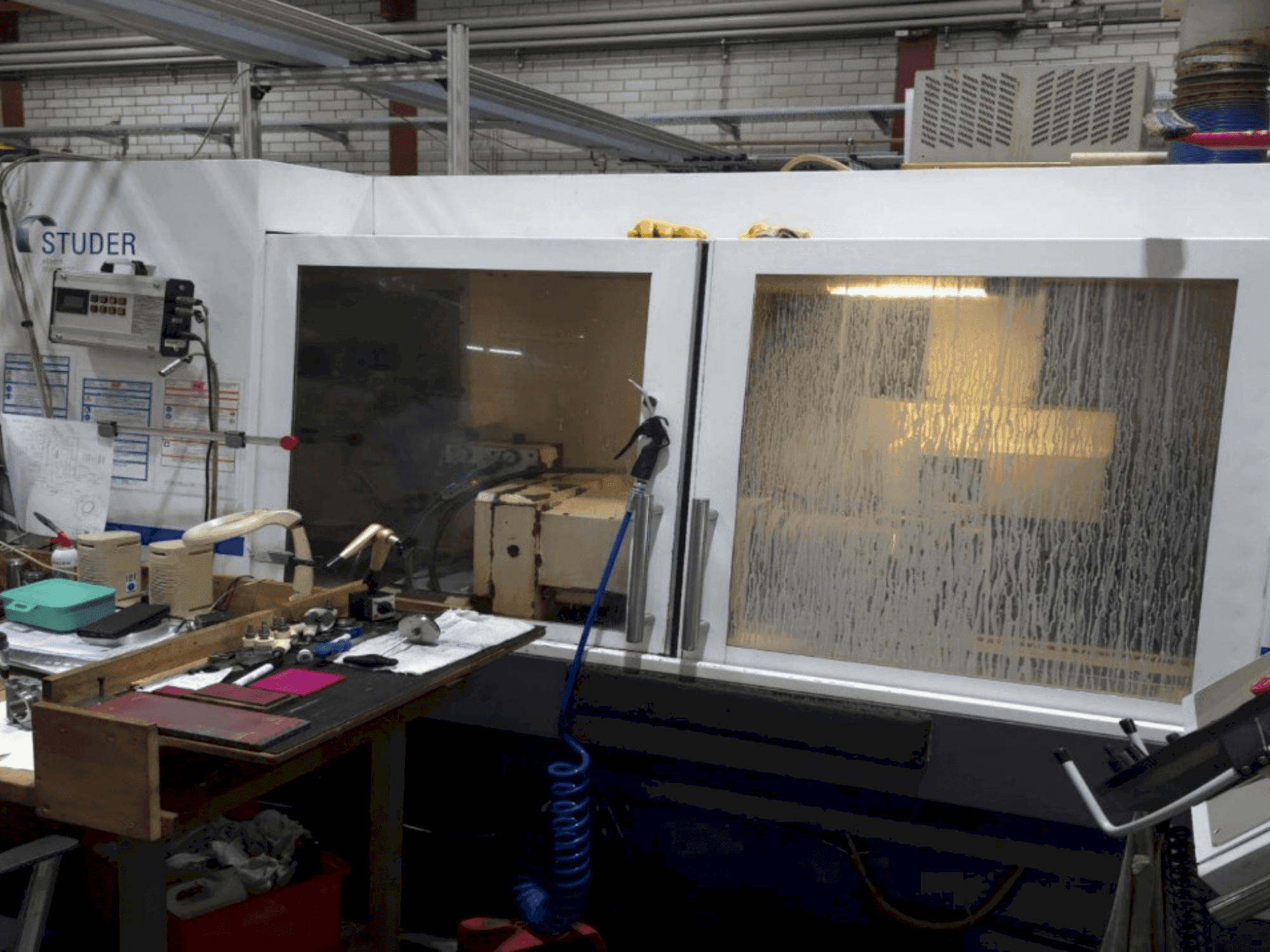

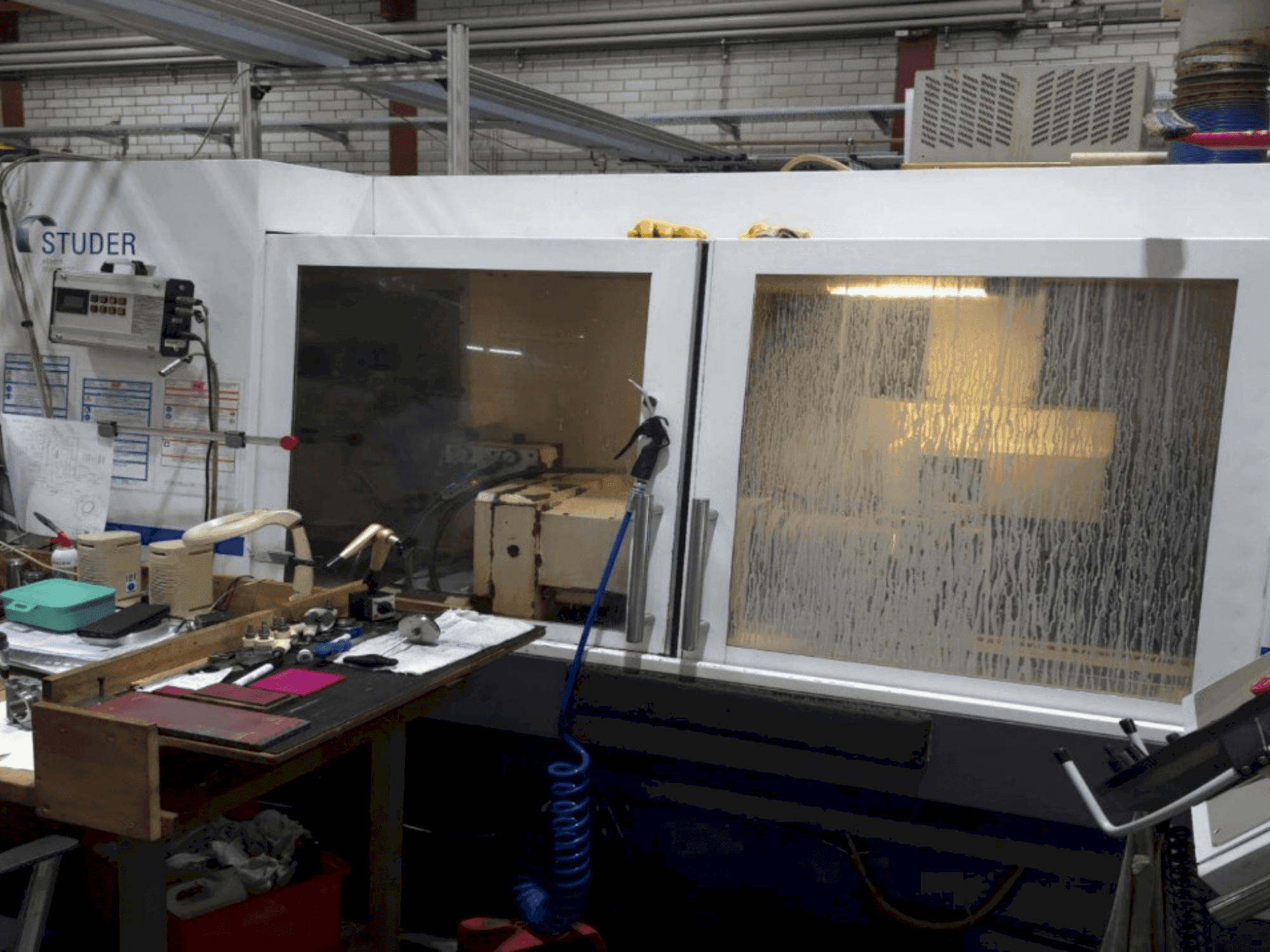

STUDER - S31DE-GRI-STU-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used STUDER S31 For Sale | gindumac.com

This STUDER S31 was manufactured in 2008. A cylindrical grinding machine featuring a GE Fanuc Series 21-TB control system. It has accumulated 47,099 operating hours with the spindle running for 25,500 hours. Consider the opportunity to buy this STUDER S31 cylindrical grinding machine. Contact us for further details regarding this machine.

Overview

- brand: STUDER

- year: 2008

- MODEL: S31

- production hours: 47099

- application type: Grinding

- Location: Germany

- machine type: Cylindrical Grinding Machine

Technical Information - STUDER S31

Main drive

- Number of axis: 2

Additional Information

Additional equipment

Frequency converter up to date / Frequency converter replaced

Machine Benefits

Technical Machine Benefits

Controller: ge fanuc series 21-tb

Tub leaking

Tank leaking

No coolant belt filter

Extra Information

Cross axis X and longitudinal axis Z:

Cross axis X (NC axis) 0°, driven by AC servo motor

and ball screw. Travel 280 mm. Feed rate programmable 0.001-5,000 mm/min.

Longitudinal axis Z (NC axis). Driven by AC servo motor and ball screw. Travel

1150 mm. Feed rate programmable

0.001-10,000 mm/min.

Direct measuring system on the X-axis

Resolution 0.0001 mm (linear, absolute measuring system,

requires no reference point travel)

Direct measuring system on the Z-axis

Resolution 0.0001 mm (linear, absolute measuring system,

requires no reference point travel)

Scale interface for direct measuring systems

Wheelhead

Turret wheelhead U universal, swiveling

Automatic wheelhead swivel axis (B-axis)

for swiveling the wheelhead.

Hirth gearing 1° to the wheelhead swivel axis. Swivel angle -15° to +195°

Safety hood in tool position 1, left Ø 500mm

for external grinding for grinding wheels Ø 500x63mm F1

(80mm F5)

Safety hood in tool position 2, right Ø 500mm

for external grinding for grinding wheels Ø 500x63mm F1

(80mm F5)

General information regarding the safety hood in tool position 2:

The grinding length of the right grinding side is reduced in the

grinding head swivel position. 300° by approx. 30%

Internal grinding device for high-frequency spindles

Ø 120mm in tool position 3 including connection cable

for connecting internal grinding spindles Ø 120mm according to

the following Studer specifications:

-- Plug-in lubrication connections for hose diameters

4mm

-- Plug-in coolant connections for forward and return flow

with hose diameters

10mm (spindle and hose-side plug-in couplings are included in the scope of delivery of the spindle)

-- With electrical connections according to the connection diagram

Internal grinding spindle coding

Fixed bearing arrangement of motor spindle 1 is on the right

at tool position 2

Cutting speed of motor spindle 1

programmable up to max. 50m/s

For motor spindles with a max. n = 3200rpm, 50m/s is

only possible with Grinding wheel diameters >300mm possible

HF internal grinding equipment for Fischer spindles with oil-air lubrication

General information on HF spindle brands:

Different spindle brands with oil-air lubrication cannot be used on one machine.

-- The number of lubrication connections must match the spindles

in the accessories.

-- Spindles with different numbers of lubrication connections cannot be used per tool position.

Maintenance unit for oil-air lubricationfor internal grinding spindles.

The lubrication quantity can be programmed spindle-specifically in the CNC control.

Air purge for HF spindles when machine compressed air is used (on from the pneumatic main valve).

Chuck workhead with roller bearings, ISO 50 taper, cylindrical external mount on

spindle nose Ø 110 mm, spindle bore Ø 50 mm.

Manual spindle locking without monitoring.

Mounting option for grinding ring sensor

General information on chuck workhead:

For live grinding or external grinding with rotating center

Manual cylindricity correction to workhead

Concentricity accuracy of at least 0.0004 mm

Standard C-axis

for workpiece loading and circumferentially positioned stopping

(Accuracy +/-0.5°) for workpiece changing

Standard C-axis; for form grinding,

a high-precision C-axis is usually required

Workpiece drive 3 kW with AC servo motor

Speed range 1-1000 rpm

Jog speed 1-50 rpm

Pneumatic lift for effortless movement

of the workhead during setup

2909914-E

Pneumatic control and chip pressure monitoring

Electrical interface 1 for rotary

dressing up to a maximum of 3 kW drive power.

Allows programmable speeds from 10–100%

of the nominal spindle speed, depending on the spindle, in the same or opposite direction as the grinding wheel.

Operating panel and control cabinet permanently connected to

the machine

Air conditioning unit for the control cabinet

General information on cooling the control cabinet:

At ambient temperature. A cooling unit is required for temperatures above 30°C.

Connection voltage: 400 volts +/-10%

Line frequency: 50 Hz +/-1 Hz

Line: 4-wire (L1, L2, L3 / PE) or 5-wire (L1, L2, L3 / N / PE)

Internal control voltage: 24 volts DC

Fanuc 21i-TB CNC controller with:

-- Active 10.4" color flat screen

-- Integrated PLC controller

-- Studer communicator and ASI bus system

User memory for CNC controller: 128 kB,

Program memory: 200

-- The Fanuc 21i-TB only supports user memory sizes up to 512 kB.

Portable operator unit: Studer PCU terminal

with LCD display, keyboard, electronic handwheel,

override and Permission button

Operating hour counter, range 0-99,999 hours

Electronic docking detection with Dittel AE 4100-1

consisting of:

-- Front panel with LCD screen for displaying

the signal curve

-- 4 inputs for docking detection with passive

sensors, whereby only one sensor can be

evaluated at a time

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to STUDER S31

LCM 220/4-220/3

SUPFINA - Surface Grinding Machine

30-15 S 2525

WALDRICH COBURG - Grinding Machine

PSGS-3060AH

Proth - Surface Grinding Machine

KGS 615 WMA1

Kent - Surface Grinding Machine

CHALLENGER ASG-1632HS

ACRA - Surface Grinding Machine

FSG 1640 AD III

WAGNER - Surface Grinding Machine

ESG-1640ASD II

EASTAR - Surface Grinding Machine

Rundschleiftechnik K52

WEISS - Grinding Machine

Fasen Fix 4.1-1500

KUHLMEYER - Grinding Machine

VM 110 CNC T

VOUMARD - Internal Grinding Machine

RP-2500-NC

DANOBAT - Cylindrical Grinding Machine

KEL VARIA RS 175/1000

KELLENBERGER - Cylindrical Grinding Machine