Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

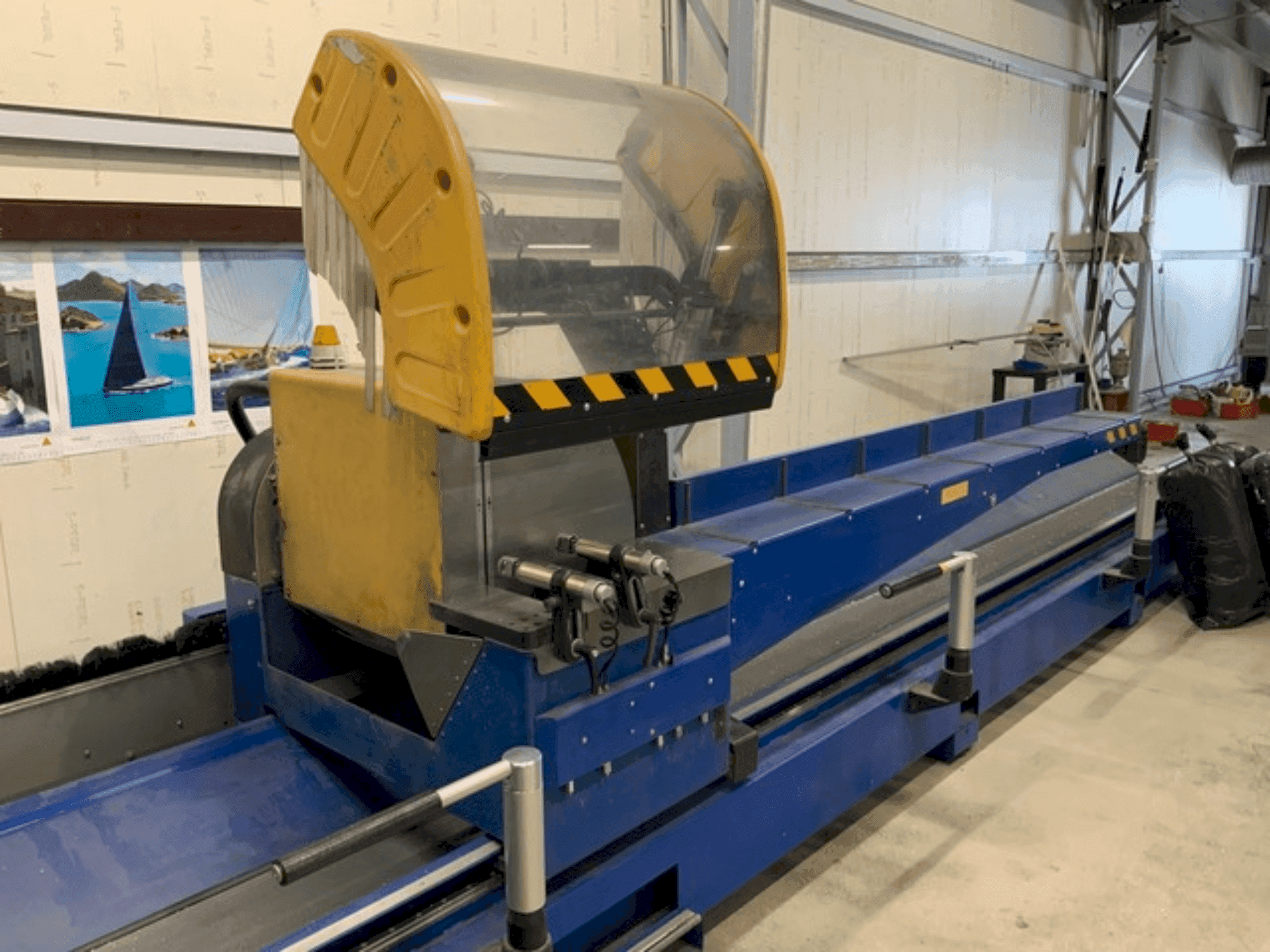

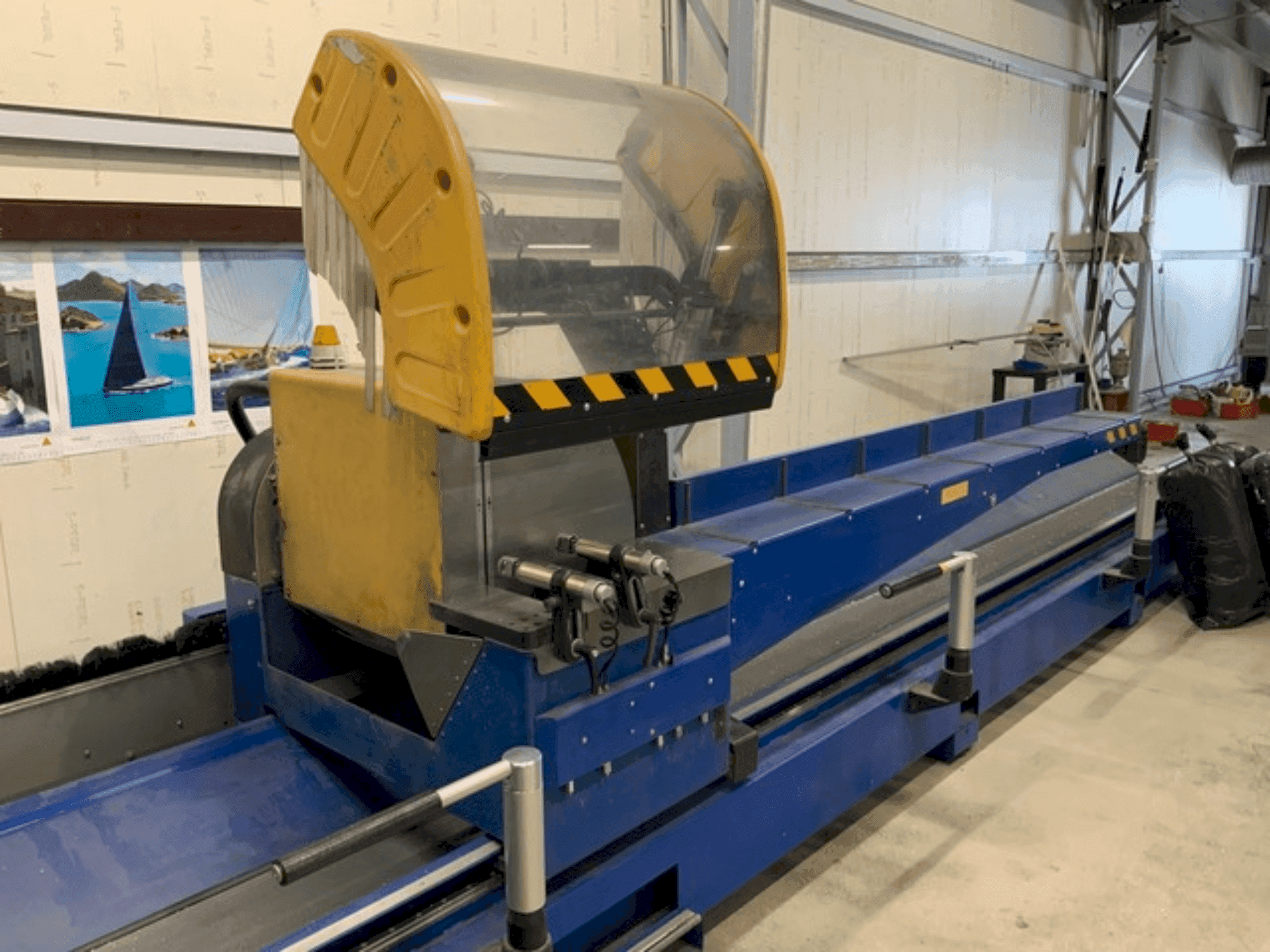

SCHÜCO - PDG e-Cut 600HU-SAW-SCH-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used SCHÜCO PDG e-Cut 600 - For Sale | gindumac.com

This SCHÜCO PDG e-Cut 600 was manufactured in 2008. It features tungsten carbide sawblades Ø600 mm, three-phase motors 4 kW at 2800 rpm, and blade rotation speed of 2410 rpm. The machine includes electronic control for head tilting, mobile head with automatic positioning, and is set up for chips and fumes extraction. Consider the opportunity to buy this SCHÜCO PDG e-Cut 600 Optimizing Cross-Cut Saw. Contact us for further details regarding this machine.

Overview

- brand: SCHÜCO

- year: 2008

- MODEL: PDG e-Cut 600

- application type: Sawing (Wood)

- Location: Hungary

- machine type: Optimizing Cross-Cut Saw

Additional Information

Additional equipment

- Integral protective hood around cutting area

- Mobile head roller table (3 m)

Machine Benefits

Qualitative Machine Benefits

- Working pressure: 7 bar (adjustable)

- Tungsten carbide sawblades Ø600 mm

- Blade holding spindle Ø 40 mm

- Indirect motor-blade transmission by belt and pulley

- Air consumption per work cycle: 53 liters

- Electrical switchboard separate from pneumatic one

- Horizontal (4) and vertical (2) pneumatic vices

- Microdrop lubrication with pure oil kit

- Three-phase motors 5. 5 kw 2800 rpm, 400 v, 50 hz

- Manual kit for undersize cutting

Technical Machine Benefits

- Three-phase motors: 4 kw, 2800 rpm, 400 v, 50 hz

- Total power absorption: 10 kw at 400 v ac

- Total absorbed current: 20 a at 400 v ac

- Heads tilt electronically controlled from 45° internal to 20° external

- First head: fixed

- Second head: mobile with automatic positioning

- Mobile head positioning speed (automatic mode): ≤ 25 m/min

- Mobile head positioning precision: ± 0. 1 mm

- Minimum and maximum cutting capacity between heads: 5000–6600 mm (depending on version)

- Double working pressure servo-controlled at low pressure

Extra Information

Machine still under power. The machine is equipped with a kit for double-speed blade exit controlled by a transducer, profile clamping with related supports, swarf and chip conveyor belts, a profile height reader on the mobile head, an external supplementary vertical vice kit, step-by-step cutting programs with multiple control options, and is prepared for integration with a chip and fume extraction system; online assistance and a label printer are also available.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing