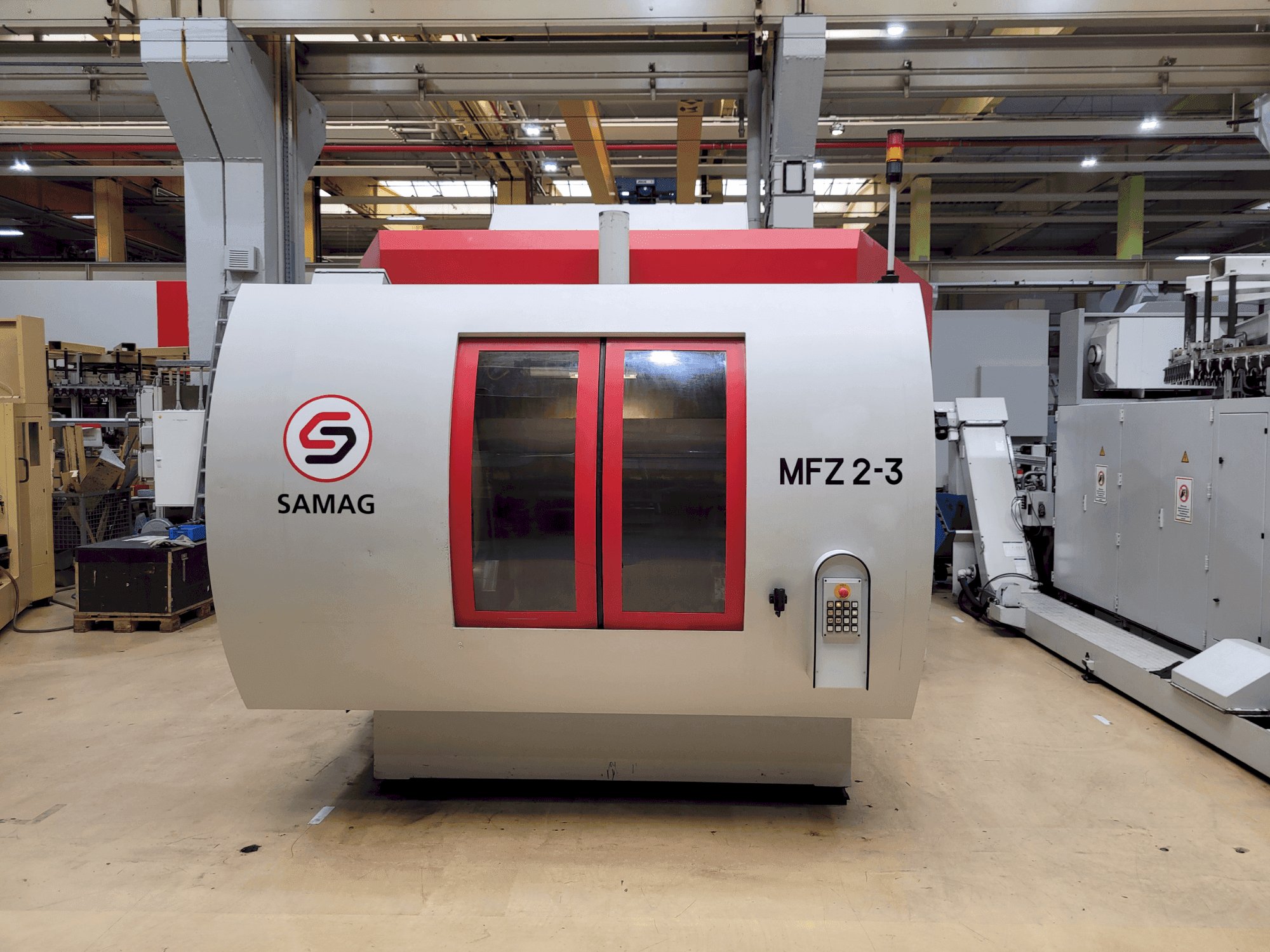

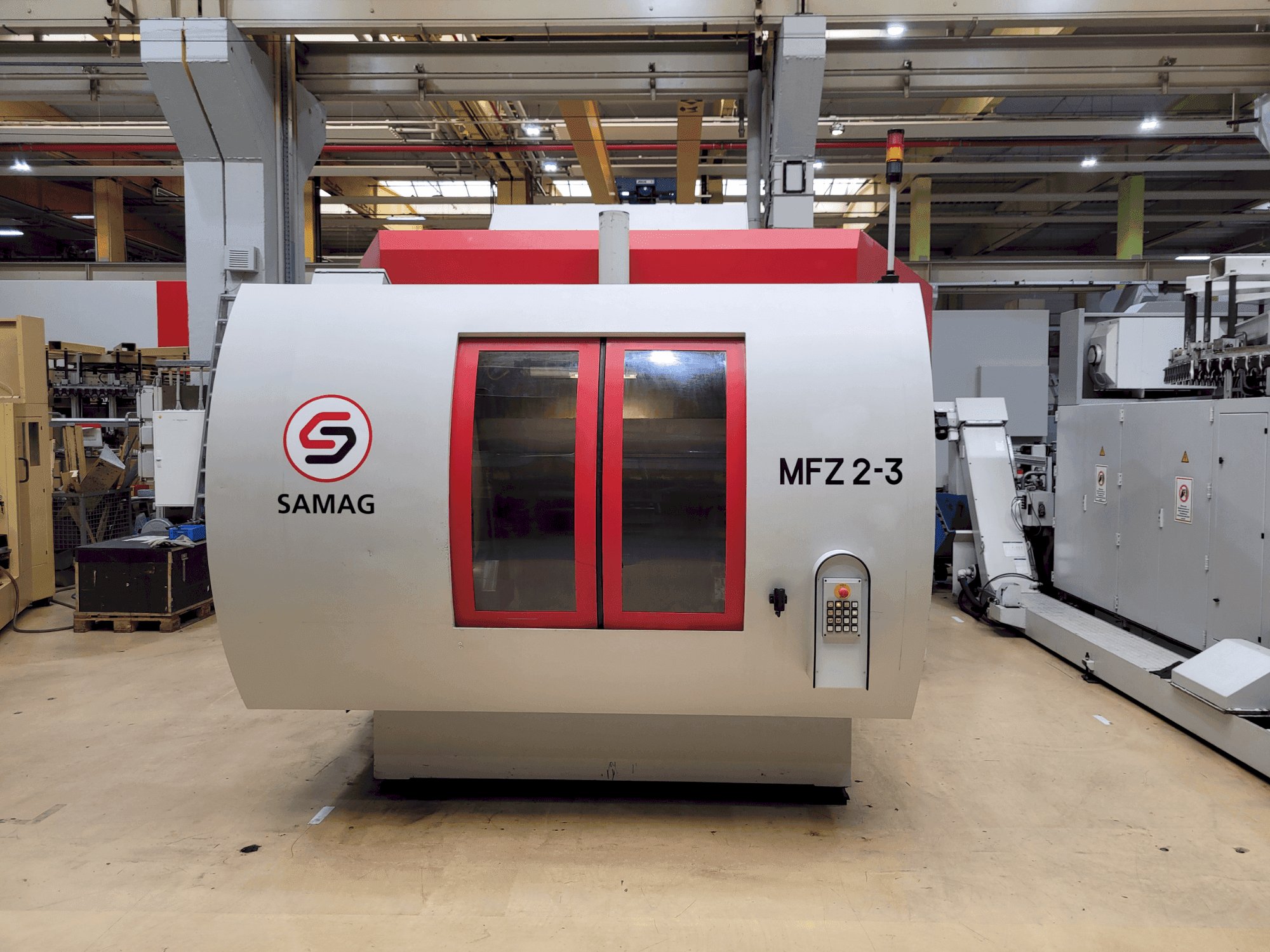

SAMAG - MFZ 2-3DE-MIL-SAM-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used SAMAG MFZ 2-3 For Sale | gindumac.com

This 3-axis SAMAG MFZ 2-3 was manufactured in 2008. It features a working area of 300x500x450 mm, rapid traverse speeds up to 60 m/min, and a tool magazine with 90 positions. The spindle supports a speed range of 50 to 16,000 rpm with a drive power of 28 kW. Ideal for high precision and efficiency in machining tasks. Contact us for more information about this machine.

Overview

- brand: SAMAG

- year: 2008

- MODEL: MFZ 2-3

- application type: Milling

- Location: Germany

- machine type: Horizontal Machining Centre

- control unit brand: SIEMENS

Technical Information - SAMAG MFZ 2-3

Control Unit

- Control Brand: SIEMENS

- Control Model: Sinumerik

Dimensions

- Machine Depth: 5450 mm

- Machine Height: 2800 mm

- Machine Weight: 20000 kg

Technical Specification

- Max. Tool Weight: 6 kg

- Spindle Power: 28 kW

- Spindle Speed: 16000 RPM

Additional Information

Machine Benefits

Technical Machine Benefits

- Required installation space (length x width): approx. 5950 mm x 6700 mm

- Weight (kg) including coolant system and chip conveyor: approx. 25000 kg

- Operating voltage: 400 v 3 n~ 50 hz

- Control/valve voltage: 24 v dc

- Machine power rating: approx. 82 kva

- Back-up fuse before main switch: 3 x 160 a

- Connector cross-section: 70 mm²

Extra Information

Ott Tool Clamping System Torque (S1/S6): 63/83 Nm Nominal Speed: 4200 rpm Spindle Bearing Diameter: 70 mm Spindle Lubrication: Lifetime grease lubrication 1 Horizontal 180° swivel support (W-axis) Faceplate Diameter (NC drive/counter bearing): 500/345 mm Permissible Tangential Torque: 15000 Nm Positioning Accuracy: ±3 angular seconds Swivel Time (0°/180°): Approx. 6 s Number of Horizontal 360° Workpiece Support Axes Positioning via Face Gearing: 120 x 3° Positioning Accuracy (120 x 3°): ±3 arc seconds Max. Transport Load per A-axis: Approx. 600 kg Permissible Tangential Torque: 5000 Nm Working Area (interference circle x length): Ø700 x 940 (1036) mm Approaching Intermediate Positions Outside the 3° Pitch: Possible (NC position control) Positioning Accuracy: ±25 angular seconds Permissible Tangential Torque: 1000 Nm Tool Magazine: 90 tool positions (3 x 30) Max. Tool Diameter with Free Adjacent Positions: 160 mm Cut-to-Cut Time (within 1 cartridge): Approx. 5.2 s Media Hydraulic Unit Capacity: 160 l Max. Operating Pressure: 160 bar Max. Flow Rate: 12 l/min Pneumatic System: Required Compressed Air Connection, Required Air Consumption (short-term) 6 ± 0.5 bar Factory Air Quality: Class 545 according to DIN-ISO 8573-1 Coolant System: Knoll coolant system with coolant cooling Coolant Tank Capacity: Max. 1400 l Separate Machine Bed Flushing: 160 l/min at 2.6 bar External Tool Cooling and Various Flushing Functions: 120 l/min at 3.5 bar Internal Tool Cooling Through the Spindles: 40 l/min at 60 bar

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing