Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

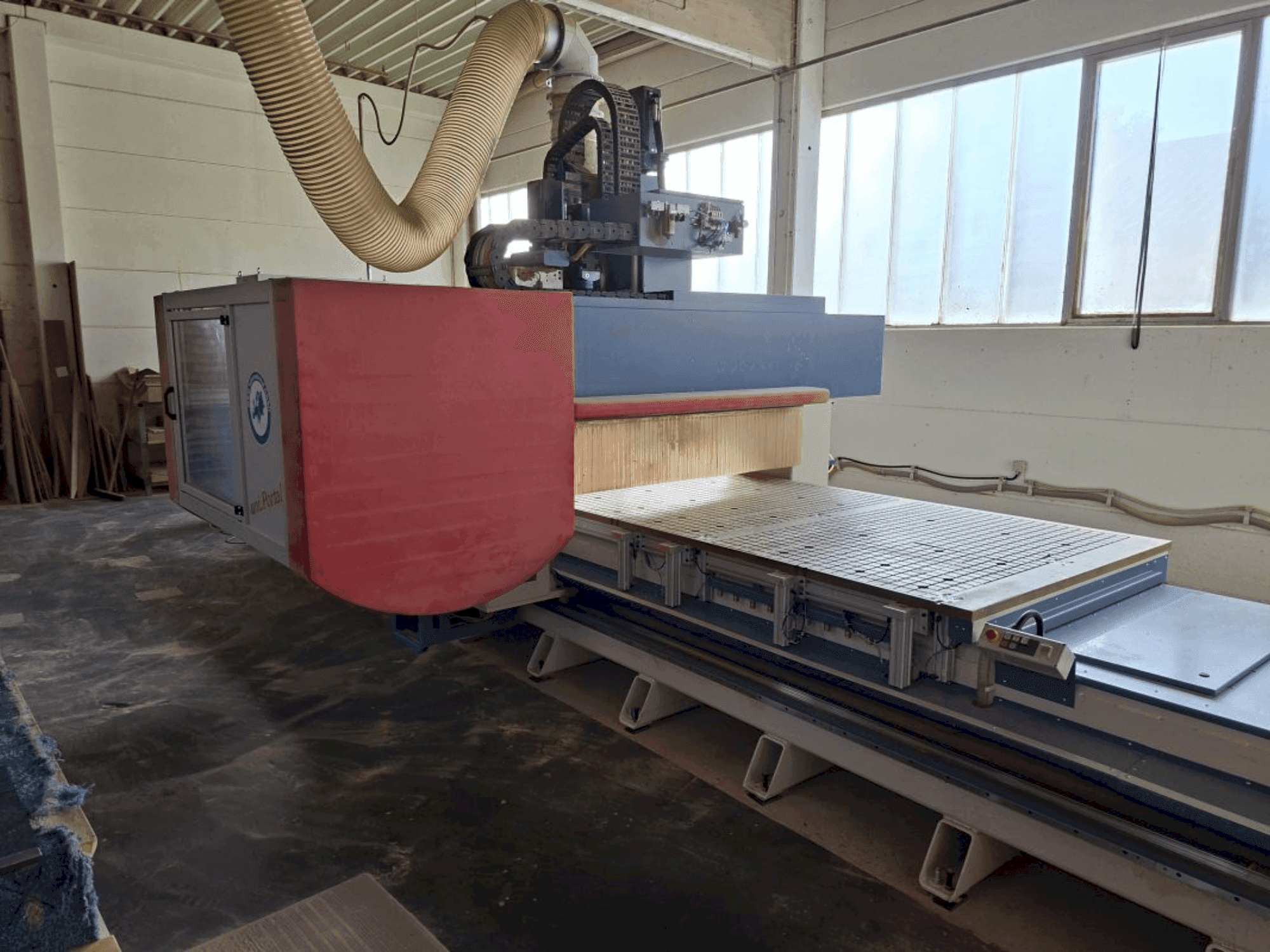

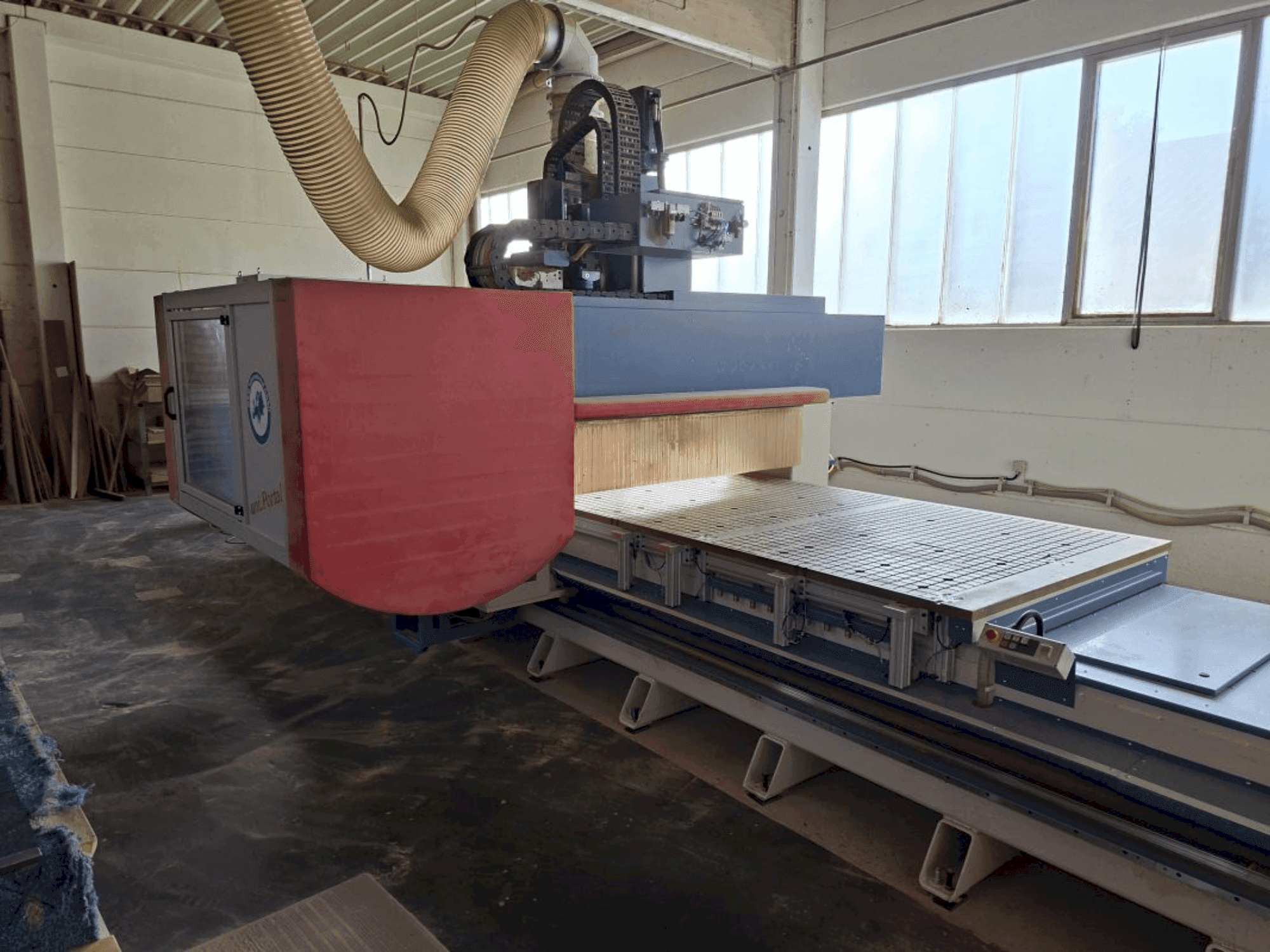

MKM - UNI Portal 50/15 RODE-CNC-MKM-2008-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used MKM UNI Portal 50/15 RO - For Sale | gindumac.com

This 5-axis MKM UNI Portal 50/15 RO was manufactured in 2008, designed for versatile machining of wood, plastics, and light metals. It features a large working area with dimensions of 5000mm x 1500mm, and a clearance height of 200mm. The machine includes a high-performance electric spindle with HSK 63 F connection and a 12-position automatic tool change magazine. Ideal for complex, multi-axis operations. If you are looking to get high-quality milling capabilities consider the MKM UNI Portal 50/15 RO machine we have for sale. Contact us for more information.

Overview

- brand: MKM

- year: 2008

- MODEL: UNI Portal 50/15 RO

- application type: CNC Wood Machining

- Location: Germany

- machine type: CNC Wood Machining Centre

Technical Information - MKM UNI Portal 50/15 RO

Movement

- Number of Axes: 5

Additional Information

Additional equipment

- Central Lubrication

- Vacuum Supply: 1 vacuum pump (Busch-Mink)

- Output approx. 250 m3/h

- 1 unit for manual operation (emergency stop, feed, hood open/close)

- Protective Fencing

- Remote Diagnosis Available

Machine Benefits

Qualitative Machine Benefits

- Machining unit for aluminum or aluminum alloys, all types of plastics, synthetic resin, resins for metal, wood, graphite for electroerosion, glass, and/or carbon fibers

Technical Machine Benefits

- Machining for: wood, plastics, light metals, stairs, doors, frames

- 4 zero points (stops) at the front left 2x and right 2x for alternating loading

- 8 pneumatic stops permanently integrated in the front part of the table

- A-axis: +/- 95°

- C-axis: +/- 210° (total 420°)

- Polar axis speed in continuous operation: 200°/sec

- Positioning accuracy of polar axes: +/-0. 02 mm

Extra Information

Tools Electric Spindle: HSK 63 F connection Automatic tool change with air cylinder Power approx. 12 kW in S1 operation (peak power = 22 kW) Spindle Speed: 24000 rpm Liquid circulation cooling integrated Integrated chip extraction Simple and quick replacement of the electric spindle Tool Change Magazine: 1 automatic tool change magazine for 12 positions (plate changer) moving in the X direction Additional Tool Position: 1 piece, as pick-up position for e.g. adapter with saw blade (max. Ø 350 mm) 1 Piece Drilling Unit, 10-Spindle: 6 spindles vertical in X direction 4 spindles vertical in Y direction

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing