Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

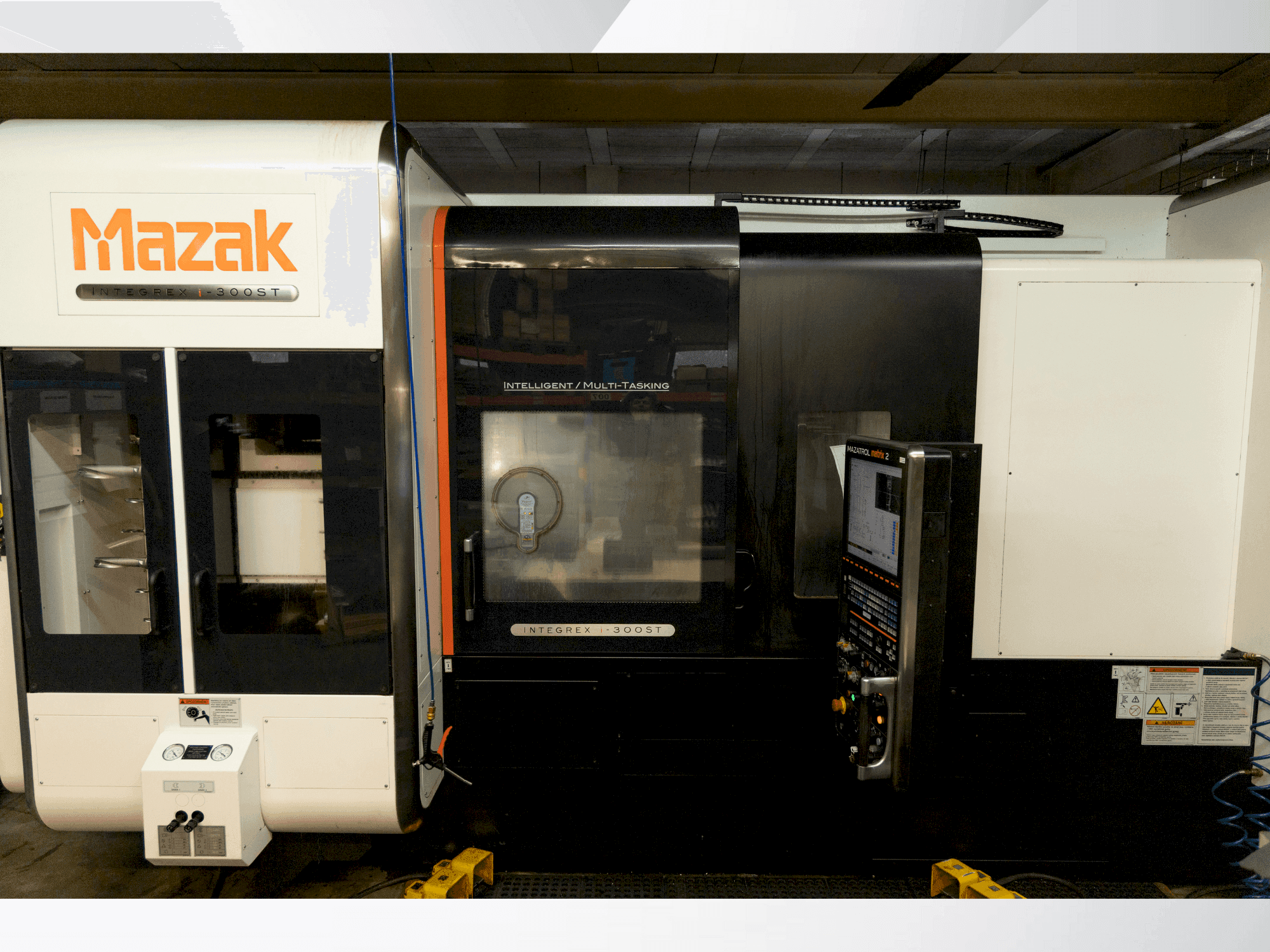

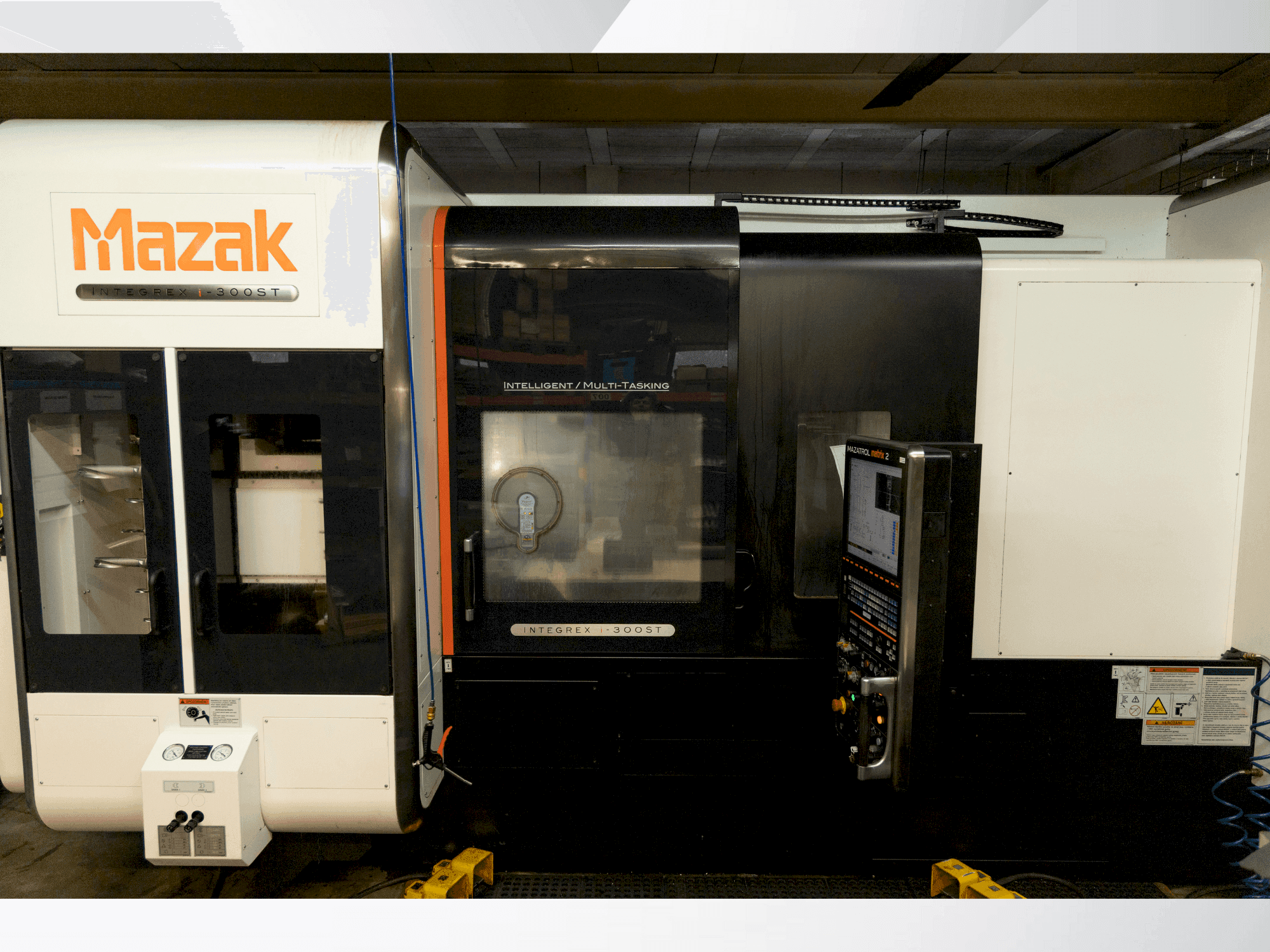

Mazak - Integrex i-300ST-1500UCZ-TUR-MAZ-2012-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Mazak Integrex i-300ST-1500U | Lathe For Sale

This 7-axis Mazak Integrex i-300ST-1500U lathe was manufactured in 2012. It features a main spindle bar passage of 80mm, a tool changer with a capacity of 72 tools, and a milling spindle speed of 12,000 rpm. Additional highlights include a high-pressure cooling system at 14 bar, a chip conveyor, and a mist filter unit. Ideal for prototype production, the machine includes tooling, chucks, and jaws. For more information about this lathe, please reach out to us.

Overview

- brand: Mazak

- year: 2012

- MODEL: Integrex i-300ST-1500U

- application type: Turning

- Location: Czech Republic

- machine type: Turn-Mill Centre

Technical Information - Mazak Integrex i-300ST-1500U

Movement

- Number of Axes: 7

- X-axis Travel: 615 mm

- Y-axis Travel: 250 mm

- Z-axis Travel: 1585 mm

Technical Specification

- Number of Tools: 72

- Spindle Speed: 4000 RPM

Additional Information

Additional equipment

- Mist filter unit

- High pressure cooling (14 bar)

- Work space rinse cleaning (2.7 bar/60 l)

- RMP600-Radio/Radio probe

- Preparation for 70 bar cooling through spindle

- Programmable overload detector

- C-axis on second spindle

- MO321 - Gear milling without tool

- TE810 - Preparation for Multi and Flash tools

- NO117 - Tool edge control for 5-axis continuous / Axes movements: X / Y / Z / X2 / Z2 615 / 250 / 1585 / 230 / 1388 mm / W 1539 mm / C-axis indexing 0.0001°

Machine Benefits

Qualitative Machine Benefits

- Comprehensive equipment for diverse machining operations (turning, milling, drilling, threading, etc. )

- Used exclusively with mazak service technicians

- Lower turret number of tools 9

Technical Machine Benefits

- Main spindle bar passage: 80mm

- Milling head (b axis) speed: 12. 000rpm

- No123 - tool radius correction for 5-axis continuous control

- No137 - eia dynamic compensation i

- No092 - synchronous threading for driven tool

- Eia/iso continuous 5-axis control

- Extensive tool capacity with 72-tool magazine (hsk-63 holders)

- Advanced 5-axis continuous control with various compensation and correction features

- Max. Machining diameter 658 mm / max. Machining length 1519 mm / max. Workpiece weight 450 (1st spindle) / 400 (2nd spindle) kg

- Main spindle motor power 30 (30 min. ) / 22 (continuous) kw / subspindle motor power 26 (30 min. ) / 22 (continuous) kw /

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing