Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

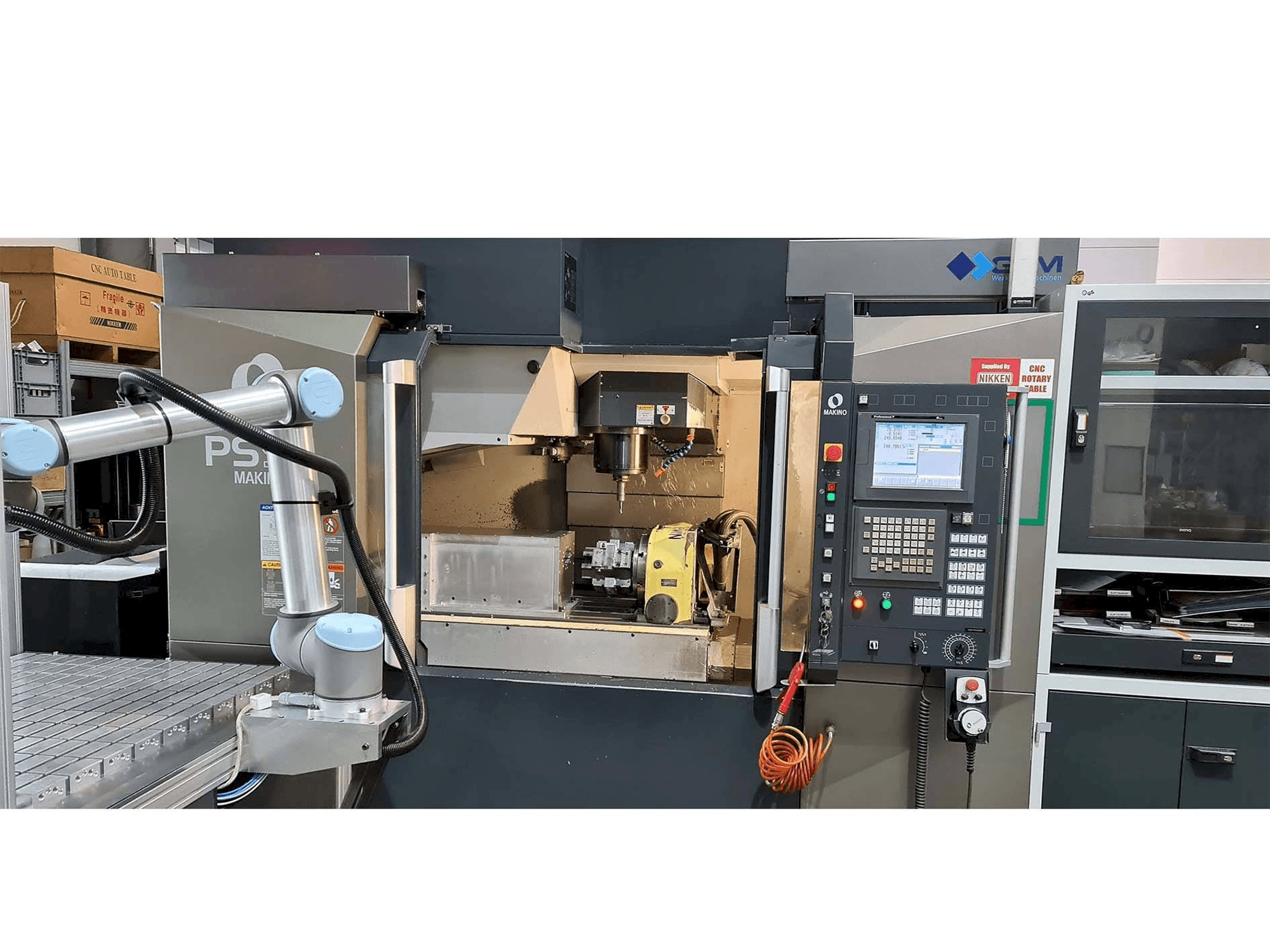

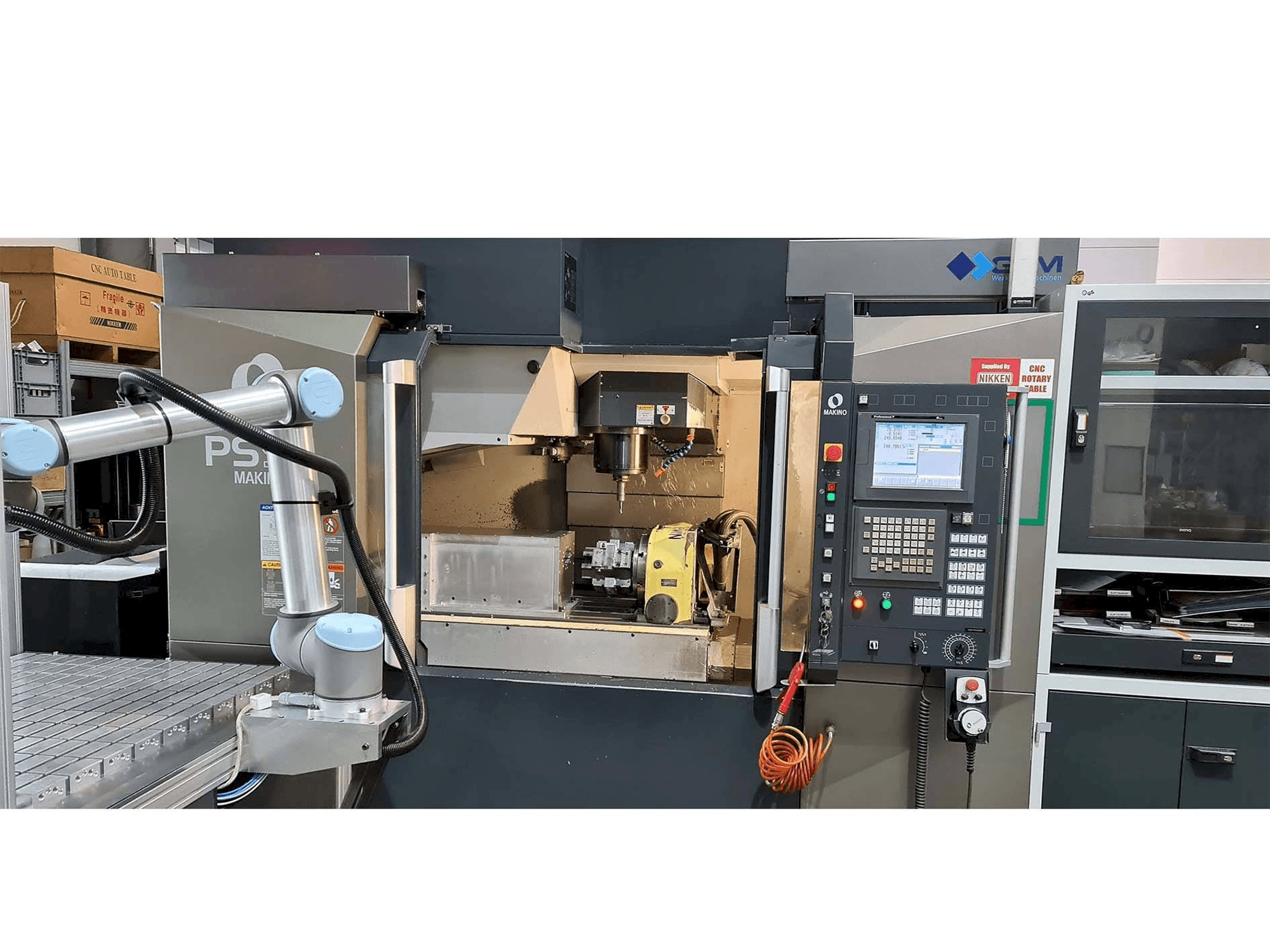

Makino - PS95DE-MIL-MAK-2012-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Makino PS95 vertical machining center

This Makino PS95 vertical machining center was manufactured in 2012 in Singapore. It includes a COBOT System von universal Robotics UR10. The machine has a total of 9750 running hours. It is operated through a Fanuc control unit. This 4 axis machine is equipped with a Gressel vice which can be controlled with a torque screwdriver via the robot at all 4 positions and has a spindle speed up to 14000 rpm.

Overview

- brand: Makino

- year: 2012

- MODEL: PS95

- production hours: 9750

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: FANUC

Technical Information - Makino PS95

Control Unit

- Control Brand: FANUC

- Control Model: with Makino surface

Dimensions

- Machine Depth: 2420 mm

- Machine Height: 2479 mm

- Machine Weight: 6800 kg

- Table Length: 1170 mm

- Table Width: 510 mm

Movement

- Number of Axes: 4

- X-axis Travel: 920 mm

- Y-axis Travel: 510 mm

- Z-axis Travel: 460 mm

Technical Specification

- Max. Tool Weight: 8 kg

- Spindle Speed: 14000 RPM

Additional Information

Additional equipment

- Software version COBOT Dec. 2021 V15.4

- COBOT System von universal Robotics UR10 is included, very easy to program

- We leave existing programs on the computer and the machine

- Table is flexible to use via simple laser inserts

- Laser floor scanner for 2 zones.

- Automatic doors via torque controlled servo motors

Machine Benefits

Qualitative Machine Benefits

- 4 axis is equipped with a gressel vice which can be controlled with a torque screwdriver via the robot at all 4 positions

Technical Machine Benefits

- 15bar ikz

- Paper belt filter for kss

- Central shearing system

- Network connection

- 4 axis nikken 260z / nc controlled / g68. 2 usable

- Door automation servo controlled : manual and programmable

- Air dryer upstream

- 45 linear guides / very accurate and stable

- Automation connection for cobot ur10

- Double gripper schunk / one side with deflection for pressing on

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing