Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

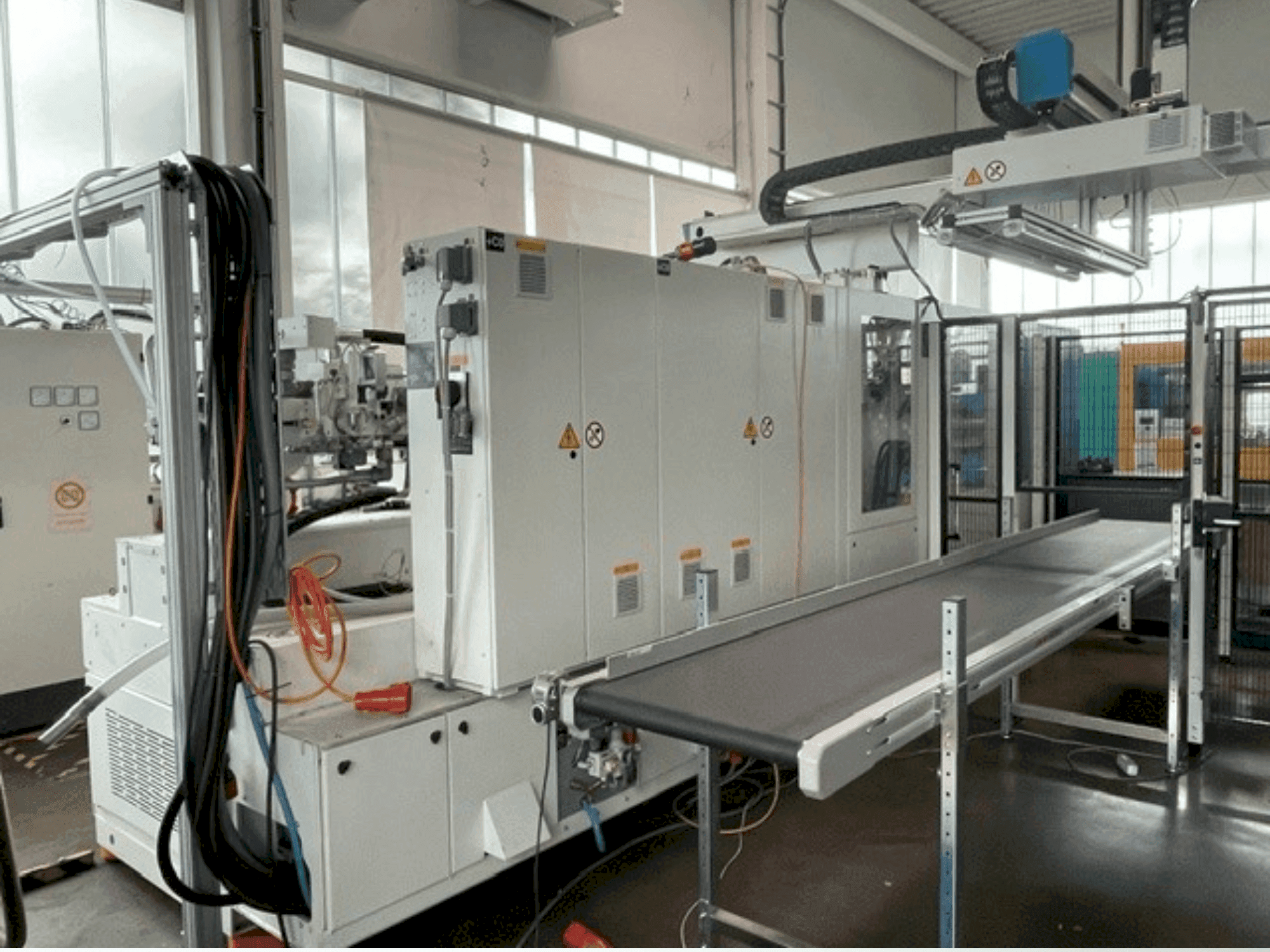

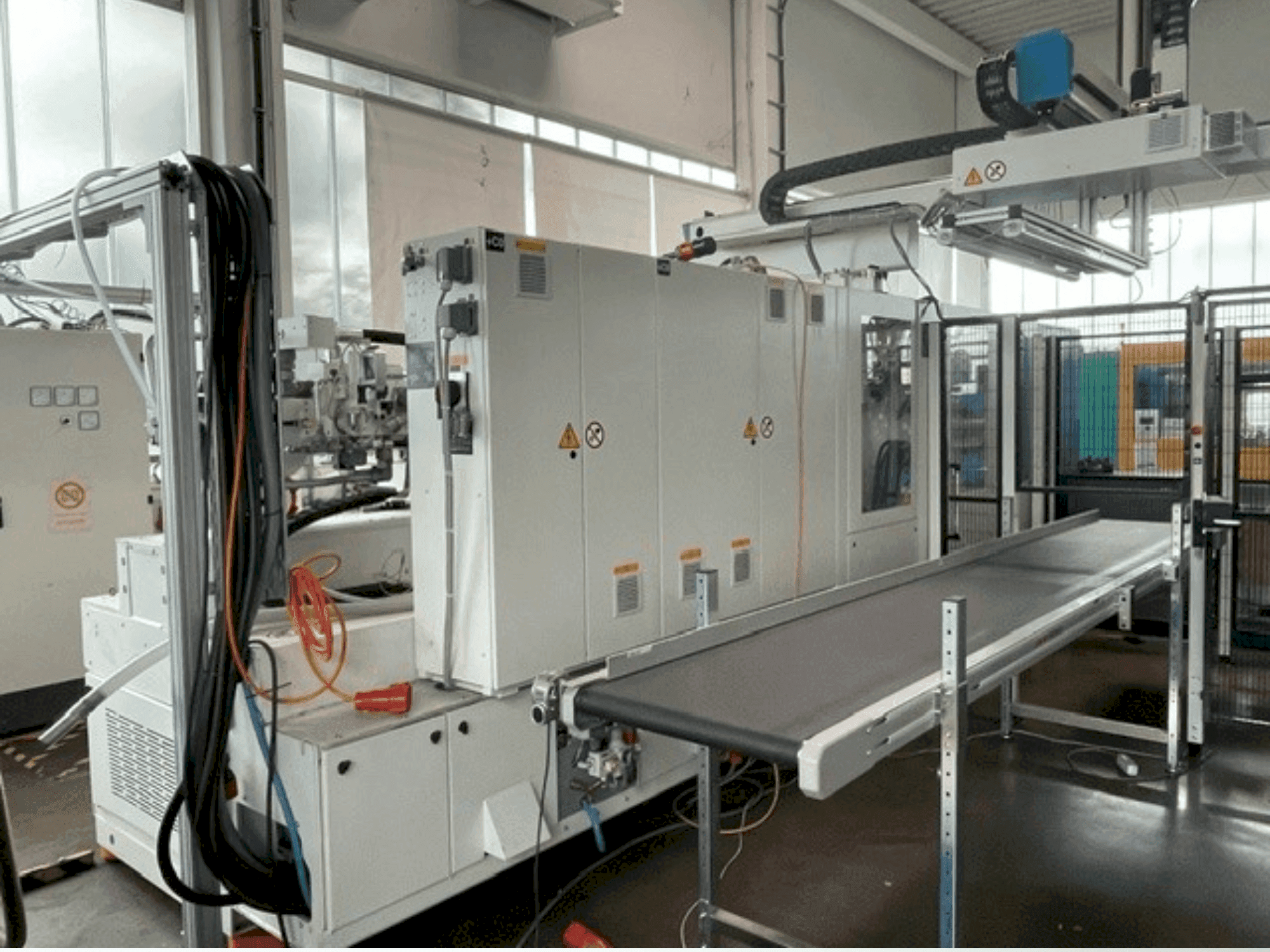

Krauss Maffei - 300-1400 CX MC6DE-OTH-KRA-2020-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Krauss Maffei 300-1400 CX MC6 | Plastic Processor

This Krauss Maffei 300-1400 CX MC6 was manufactured in 2020. It features a hydraulic screw drive, oscillating mounts for stability, and a comprehensive service unit for compressed air preparation. The machine supports high weight loads with its robust clamping unit and has chrome-plated tie bars for durability. Consider the opportunity to buy this Krauss Maffei 300-1400 CX MC6 plastic processing machine. Contact us for more information about this machine.

Overview

- brand: Krauss Maffei

- year: 2020

- MODEL: 300-1400 CX MC6

- application type: Other Plastic Processing Machinery

- Location: Germany

- machine type: Plastic Processing Machine

Technical Information - Krauss Maffei 300-1400 CX MC6

Dimensions

- Machine Weight: 19300 kg

Additional Information

Additional equipment

Weight: 19,300 kg

Oscillating Mounts for Machine Mounting

Support for Clamping Unit on Foundation (for high weight loads, e.g., large tools or turning devices)

Clamping & Injection Unit

Chrome-Plated Tie Bars

Clamping Unit and Injection Unit with Internal Oil Filtration in the Bypass Flow

Manual Ejector Coupling System:

Machine-side and tool-side coupling elements

3 thread adapters for customer-supplied ejector pins

Hook wrench

Compensates for minimal axis offset between machine and mold ejector

“Rear” end position of ejector and mold ejector plate monitored in series

Mold Platen Widening

KM 65 / 80 CX: 50 mm

KM 110 / 130 CX: 60 mm

KM 160 CX: (not specified)

KM 200 CX: 70 mm

KM 250 / 300 CX: 80 mm

KM 350 CX: 90 mm

KM 420 CX: 100 mm

Note: Position affects mechanical interface according to EUROMAP 18 for handling device on FWAP (with intermediate plate up to KM 420 CX)

Hydraulic & Pneumatic Systems

Hydraulic Screw Anti-Rotation Lock

Hydraulic Screw Drive with Standard Speed

Pneumatic and Hydraulic Cascade Valves for Hot (Cold) Channel Needle Valve:

Hydraulic: 2 × 4/3-Way Valves with 2 Solenoid Coils, connection fitting size 12 S (24° cone DIN EN ISO 8434-1)

Pneumatic: 2 × 5/2-Way Valves with 2 Solenoid Coils, connection via hose connector to FWAP BGS

Cascade control selectable on screen for pneumatic or hydraulic operation

Compressed Air Service Unit

Service Unit Combination for Compressed Air Preparation:

Manual shut-off valve with pressure relief

Manual pressure adjustment valve with gauge and air filter

Pressure switch for electrical monitoring

Electric shut-off valve with pressure relief

Nozzle & Ejector Chamber Control

Nozzle and Ejector Chamber Control and Monitoring Systems:

Control for opening/closing tool nozzles based on distance or time

Tool nozzles can open/close twice during injection and holding pressure

Time-delayed closure after holding pressure

Monitoring of at least one open tool nozzle

Manual operation in setup mode

Nozzle guard can be opened opposite operator

Ejector chamber protective door can be opened on operator side

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing