Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

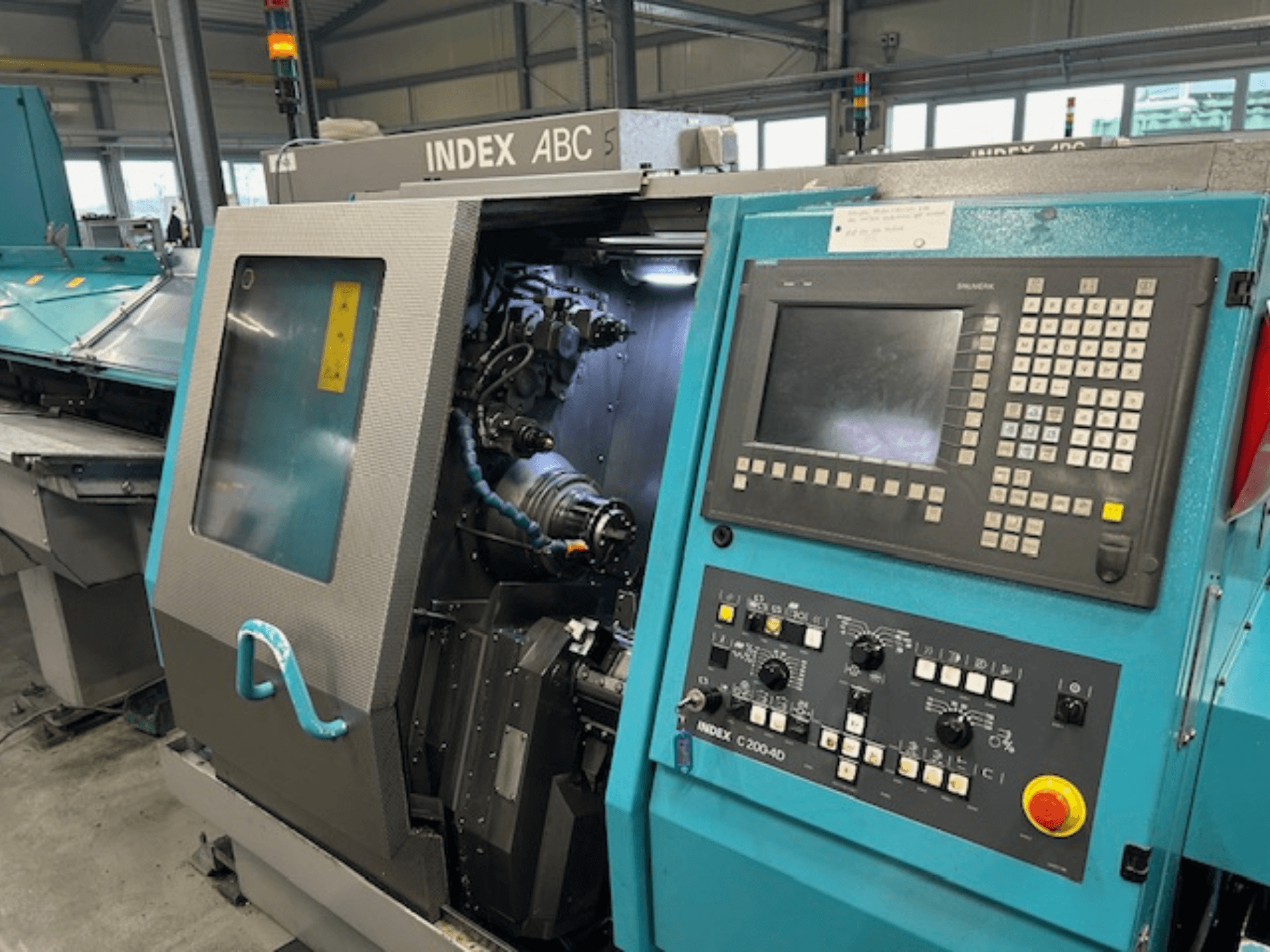

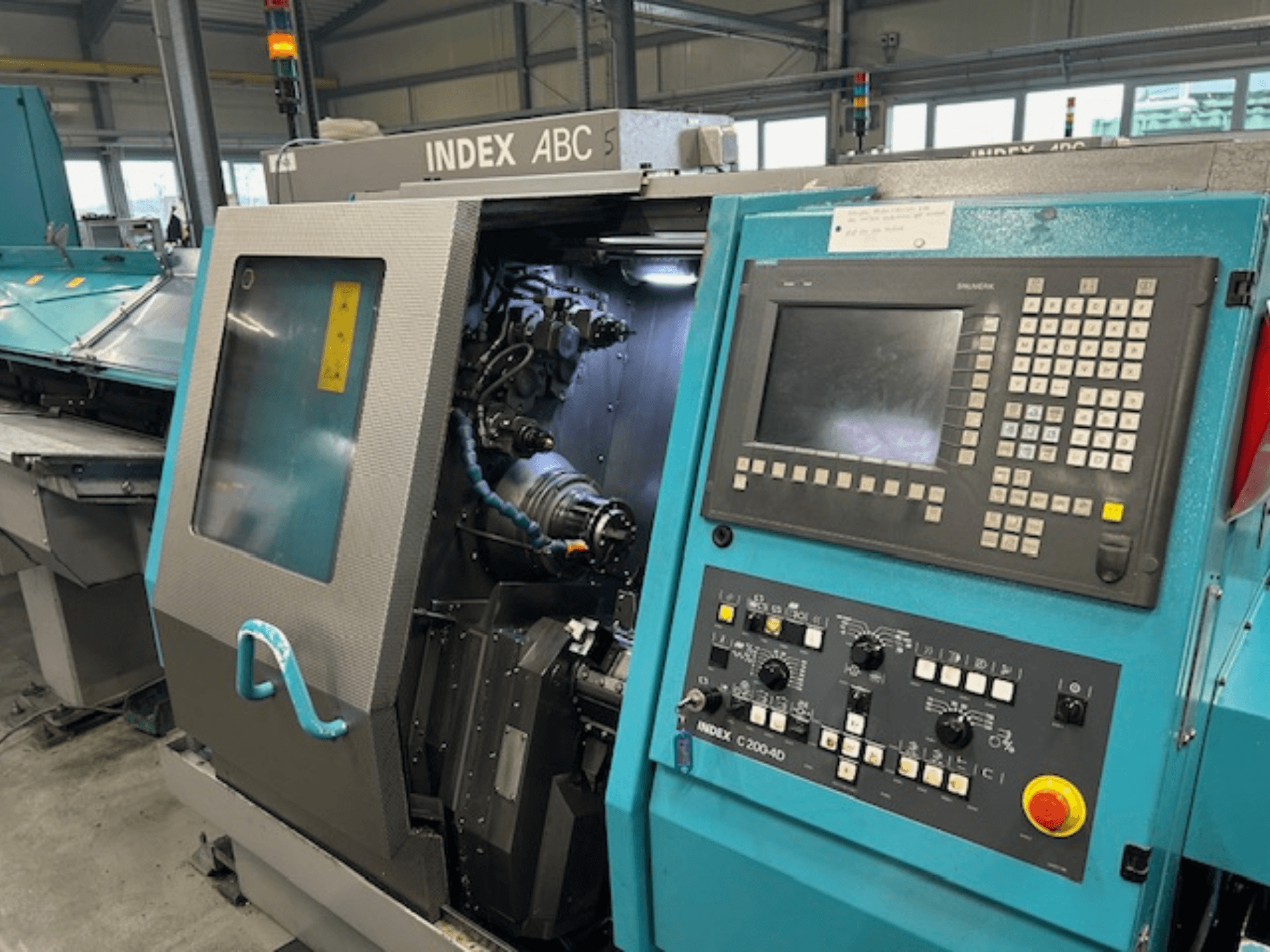

Index - ABCDE-TUR-IND-2007-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Index ABC Horizontal Lathe For Sale | gindumac.com

This 4-axis Index ABC horizontal turning machine was manufactured in 2007. It features a spindle clearance up to 65 mm, spindle diameters up to 100 mm, and a maximum spindle speed of 7500 rpm. The machine includes two turrets, each with rapid traverse rates of 27 m/min and 36 m/min for the X and Z axes, respectively. It supports bar diameters up to 52 mm and has a coolant system with a flow rate of 60 l/min. Consider the opportunity to buy this Index ABC horizontal turning machine. Contact us for more information.

Overview

- brand: Index

- year: 2007

- MODEL: ABC

- production hours: 48820

- application type: Turning

- Location: Germany

- machine type: Horizontal Turning Machine

Technical Information - Index ABC

Dimensions

- Machine Height: 1750 mm

- Machine Weight: 2500 kg

Additional Information

Main spindle

Capacity variants (spindle clearance):

30 (25): 30 mm (25 mm)

42 (36): 42 mm (36 mm)

60 (52): 60 mm (52 mm)

65: 65 mm

Spindle diameter in front bearing:

75 mm (Model 30)

85 mm (Model 42)

100 mm (Models 60 & 65)

Power Pmax at 100% duty:

7 / 10 / 13 kW (Model 30)

7.5 / 13 / 20 kW (Model 42)

7.5 / 13 / 20 kW (Model 60)

13 / 20 kW (Model 65)

Power Pmax at 40% duty:

10 / 15 / 21 kW (Model 30)

13.3 / 21 / 29 kW (Models 42 & 60)

21 / 29 kW (Model 65)

Torque Mdmax at 100% duty:

33 / 48 / 62 Nm (Model 30)

35 / 62 / 95 Nm (Models 42 & 60)

62 / 95 Nm (Model 65)

Torque Mdmax at 40% duty:

48 / 69 / 102 Nm (Model 30)

64 / 102 / 140 Nm (Models 42 & 60)

102 / 140 Nm (Model 65)

Max speed:

7500 rpm (Model 30)

7000 rpm (Model 42)

6000 rpm (Models 60 & 65)

Clamping cylinder stroke:

Collet clamping: 7 mm

Chuck and collet clamping: 20 mm

Clamping path monitoring: 140 mm (with Rev. 2) / 160 mm (without Rev. 2)

Expansion stages:

C-axis resolution: 0.001°

Alignment/switching unit (indexing angle): 2.5°

Workpiece stop and ejector unit: D 42 / D 60

Tool carrier: Turret 1

Slide travel: X 90 mm, Z 280 mm

Feed force: 5500 N (X and Z)

Rapid traverse: X 27 m/min, Z 36 m/min

Resolution: X 0.5 µm, Z 1.0 µm

Number of tools: 7 + synchronous spindle

Tool system: Cylindrical shank DIN 69 880 (25 x 48 mm)

Switching time (one station): 0.3 s

Tool drive (all stations): 4.2 kW, 7.5 Nm, 6000 rpm (Pmax/Mdmax at 25% duty)

Tool carrier: Turret 2

Slide travel: X 81 mm, Z 80 mm

Feed force: X 8300 N, Z 5500 N

Rapid traverse: X 27 m/min, Z 36 m/min

Resolution: X 0.5 µm, Z 1.0 µm

Number of tools: 6

Tool system: Dovetail mount with cylindrical shank (25 x 40.3 mm)

Switching time (one station): 0.3 s

Tool drive (all stations): 6.5 kW, 14 Nm, 4500 rpm (Pmax/Mdmax at 25% duty)

Thread milling and polygon turning unit: max 6000 rpm (max 2 stations simultaneously)

Rear tool carrier (back-working)

Slide travel: X 280 mm, Z 280 mm

Max number of tools: 6

Tool system: Dovetail mount

Back-boring unit (optional expansion)

Max fixed tools: 5

Max driven tools: 2

Driven tools performance (at 25% duty): 4.5 kW, 8 Nm, 6000 rpm

Tool holder bore: 25 mm (DIN 69 880) / 1 inch

Material handling (integrated material feed unit)

Bar diameter max: 52 mm

Adjustable feed path max: 80 mm

Feed force: 3000 N

Fluids and systems

Coolant system: 60 (80) l/min, 5.5 (8) bar, tank 220 l; switchable pump max 18 bar, 20 l/min

Hydraulic system: 19 l/min, 90 bar, tank 50 l

Dimensions (without loading magazine and chip conveyor)

Floor area: 2.4 m²

Spindle center height (above floor): 1010 mm

Additional equipment

Bar loading magazine (bar feeder), models LM3200 / LM3700 / LM4200

Bar length max: 3.2 m / 3.7 m / 4.2 m

Bar diameter range: 6–52 mm

Chip conveyor

Type: Hinge type or scraper belt

Discharge height: 840 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing