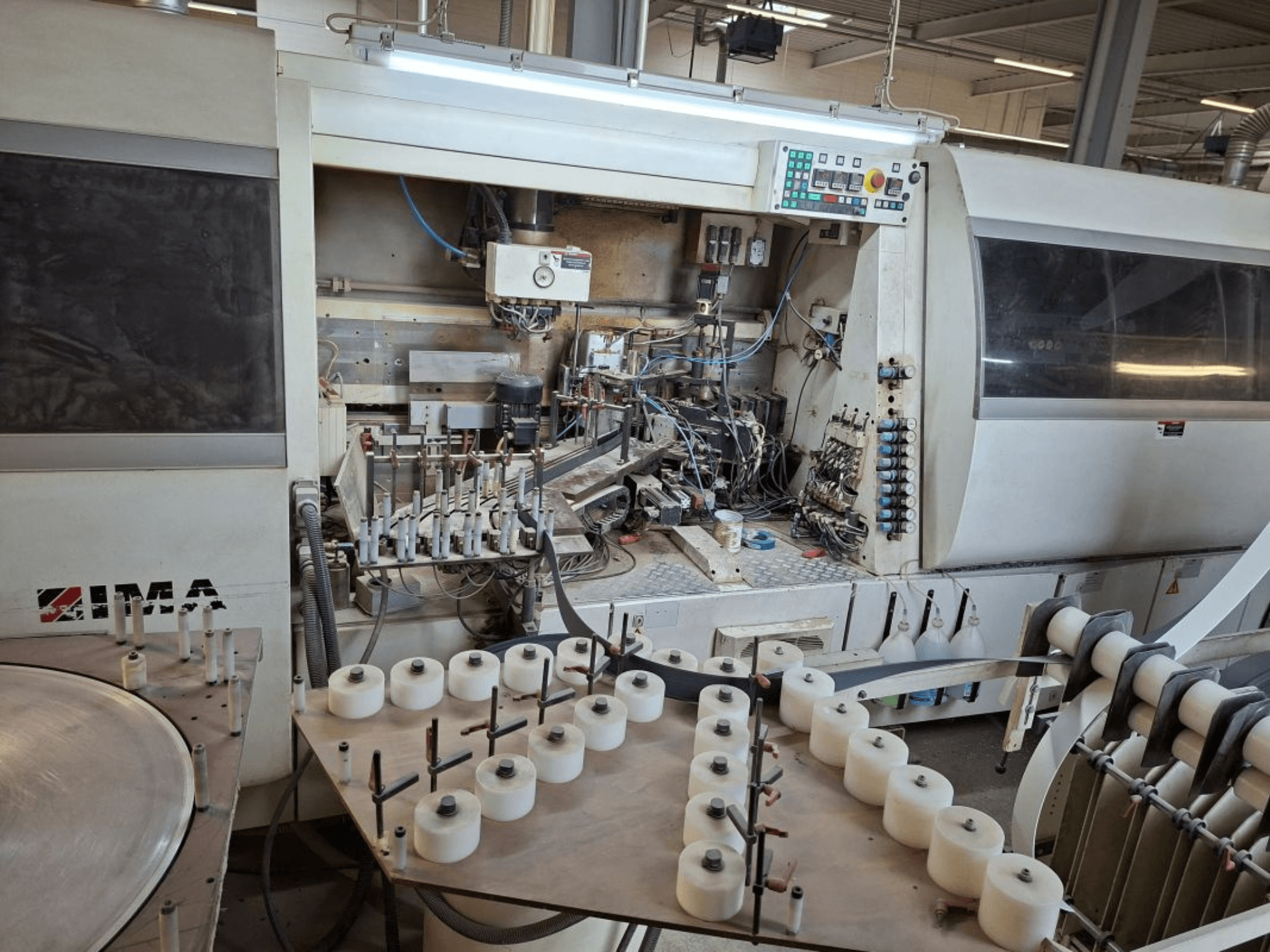

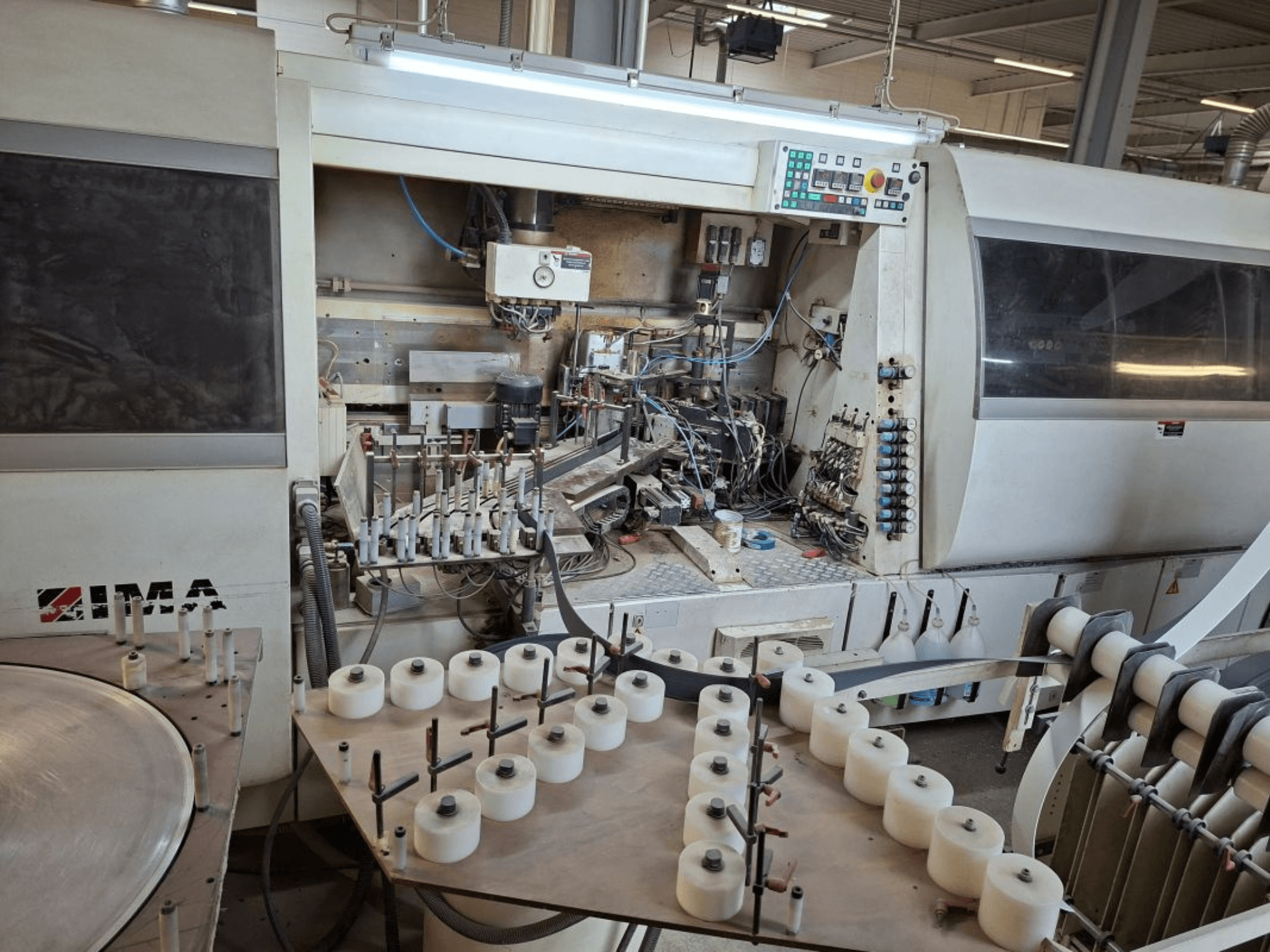

IMA - Combima Systems/I/R75/1370DE-EDG-IMA-2006-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used IMA Combima Systems/I/R75/1370 | Edgebander

This IMA Combima Systems/I/R75/1370 edgebander was manufactured in 2006. It handles workpieces ranging from 250 to 2800 mm in length and 115 to 1300 mm in width, with thicknesses up to 40 mm. Designed for materials like chipboard and MDF, it features a hot melt adhesive applicator and a servo edge feed system. Ideal for high-quality edge banding, consider the opportunity to buy this IMA Combima Systems/I/R75/1370 edgebander. Contact us for more information about this machine.

Overview

- brand: IMA

- year: 2006

- MODEL: Combima Systems/I/R75/1370

- application type: Edge Banding

- Location: Germany

- machine type: Edgebander

Additional Information

Workpiece (chipboard/MDF)

Workpiece length: 250–2800 mm

Workpiece width: 115–1300 mm

Workpiece thickness: 8 mm (format only) to 40 mm

Smallest workpiece: 144 × 250 × 8 mm

Largest workpiece: 2800 × 1300 × 38 mm

Workpiece weight: max. 50 kg

Workpiece shape: rectangular

Surface material: direct coating (melamine), paper, foil, veneer

Coating material overhang at sides: 10 mm

Workpiece (honeycomb panel; min. feed length 300 mm)

Cover thickness: 3.0 / 4.0 / 8.0 mm

Machining allowance: edge thickness

Workpiece length: 300–2800 mm

Workpiece width: 300–1300 mm

Workpiece thickness: 15–100 mm (with 3 mm support edge only as double panel)

Smallest workpiece: 300 × 300 × 15 mm

Largest workpiece: 2800 × 1300 × 100 mm

Workpiece (frame panel; min. feed length 300 mm)

Cover thickness: 8.0 mm

Machining allowance: 5.0 mm

Frame material: vertically arranged chipboard (reduced feed)

Workpiece length: 300–2800 mm

Workpiece width: 300–1300 mm

Workpiece thickness: max. 50 mm

Edge material and profiles

Paper & plastic edges: 0.3–3.0 mm

Veneer edges: 0.5–1.3 mm

Support edge: 3.0 mm

Edge height: 19–104 mm (support edge 97 × 3 mm only for double panels)

Max. upper edge overhang: 2 mm

Edge profiles:

Paper edge: approx. 0.4 mm, chamfer 15°

Plastic edge: 3.0 mm, radius 3 mm

With servo cutting knife (2 gluing section):

Max. edge cross-section: 200 mm² (plastic), 135 mm² (veneer)

Machine data

Constant workpiece clearance from chain conveyor: 38 mm (incl. edge thickness 0.3–3.0 mm)

Throughput width (with 38 mm clearance): min. 115 mm

Workpiece length in feed direction: min. 150 mm

Base height (upper edge of chain conveyor): 960 mm

Feed speed: 6–30 m/min, frequency-controlled

Processing units and systems

Milling/profile milling/grooving units:

1 × 6.6 kW, 100 Hz, 6000 rpm

1 × 8.0 kW, 100 Hz, 6000 rpm (double clamping unit drive)

1 × 4.4 kW, 100 Hz, 6000 rpm

1 × 4.4 kW, 100 Hz, 6000 rpm

1 × 4.4 kW, 100 Hz, 6000 rpm

1 × 8.0 kW, 100 Hz, 6000 rpm

Hot-melt adhesive applicator for 2 adhesive beads

300 lg radiator, 2 × 1.5 kW for preheating the workpiece edge

Gluing unit for straight edges; edge thickness up to 3 mm (depending on magazine)

Automatic PU melting system: Quickmelt

2-fold edge magazine for roll material (0.3–3.0 mm)

Servo knife for precise edge cutting

Servo edge feed (incl. for support edges in roll form)

Glue application for workpiece thickness up to 90 mm

Cutting unit: 2 × 660 W, 200 Hz

Milling unit: 1 × 1000 W, 400 V, 200 Hz, 12,000 rpm, 30° swivel

Multiple machining unit: 1 × 660 W, 400 V, 200 Hz, 12,000 rpm

Multiple profile scraper unit

Milling unit: 1 × 1000 W, 400 V, 200 Hz, 12,000 rpm, 30° swivel

Multiple machining unit: 1 × 660 W, 400 V, 200 Hz, 12,000 rpm

Multiple profile scraping device

Self-probing scraping unit

Buffing unit

Additional equipment

Inclined roller table SFR 1450/2260/15° for longitudinal and transverse operation:

Workpiece length (manual feed): 300–2800 mm

Workpiece width: 190–1300 mm

Workpiece thickness: 13–60 mm

Servo insertion system x20

Servo stop system x20

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing