Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

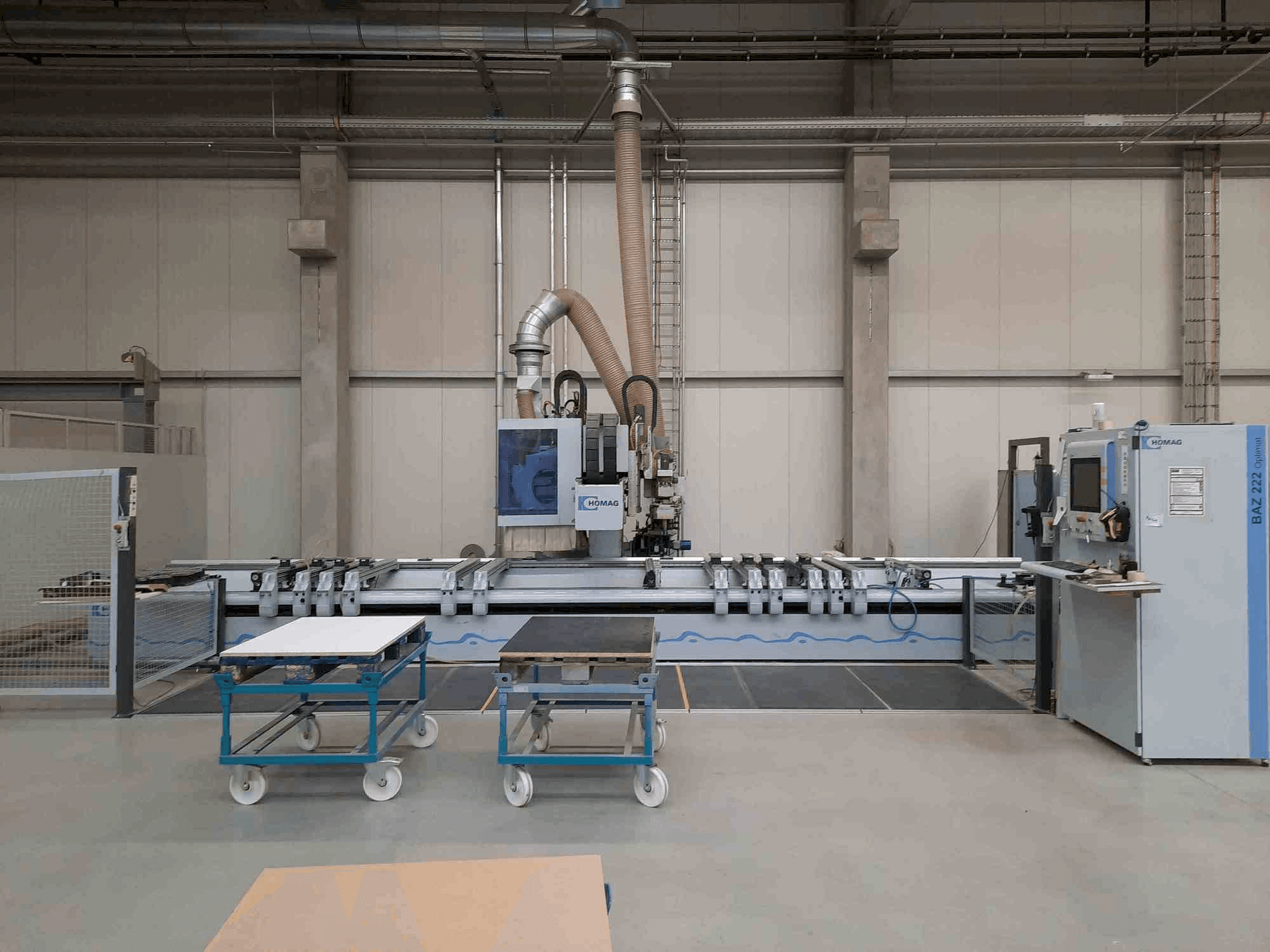

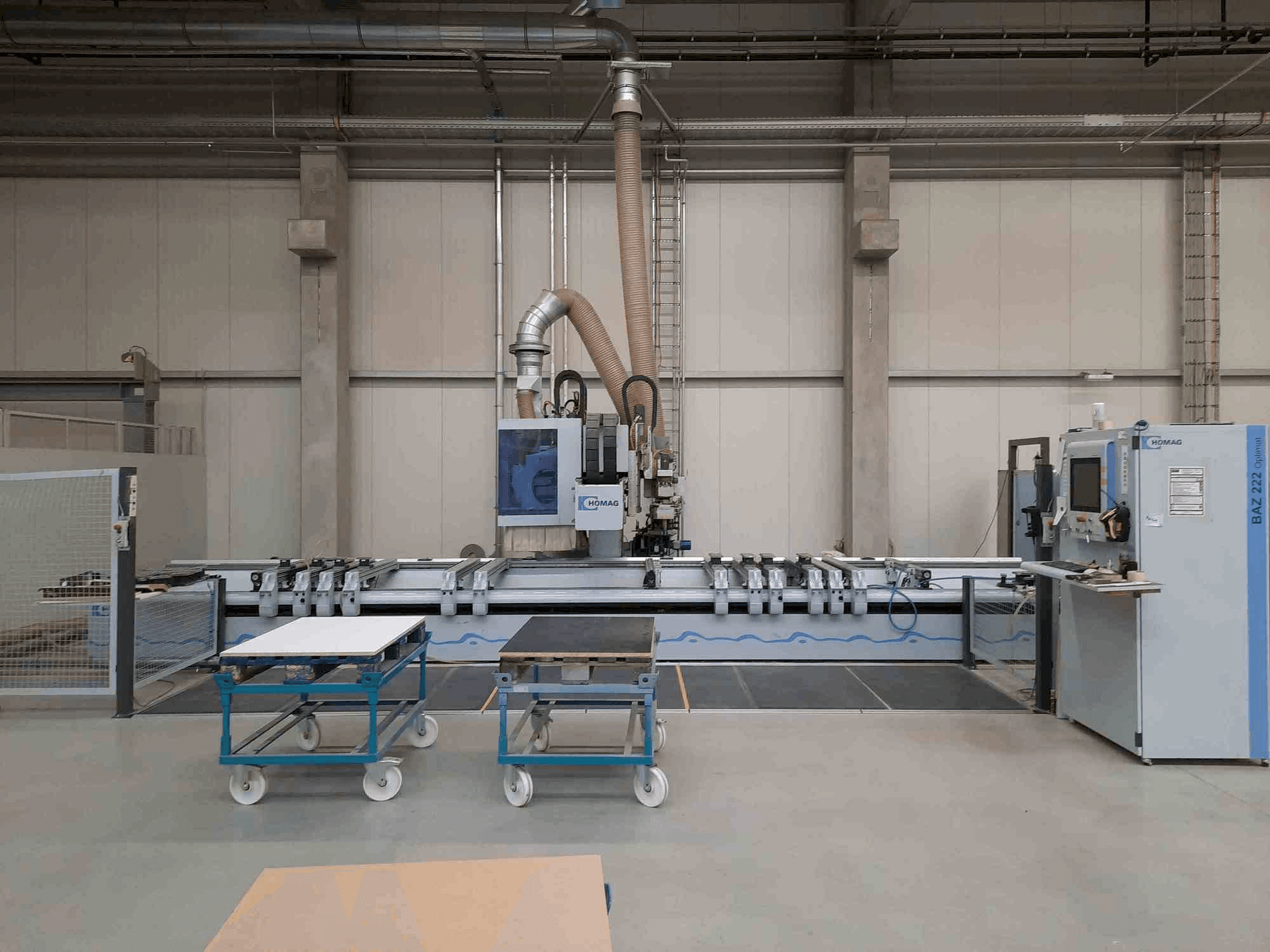

HOMAG - OPTIMAT BAZ222/60/KDE-WOO-HOM-2010-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOMAG OPTIMAT BAZ222/60/K - For Sale

This CNC processing centre was manufactured in 2010. It features a main spindle of 15 KW with HSK F63, an 18-fold plate changer, and a 30-spindle drilling head. Equipped with a POWER EDGE gluing unit for precise edge banding and a FLEX-5 unit for enhanced versatility. Ideal for handling large workpieces with a maximum thickness of 300 mm. For more information about this woodworking processing centre, please reach out to us.

Overview

- brand: HOMAG

- year: 2010

- MODEL: OPTIMAT BAZ222/60/K

- application type: CNC Wood Machining

- Location: Germany

- machine type: CNC Processing Center

Additional Information

Additional equipment

- Gluing unit with FLEX-5 unit

- Main spindle 15 KW, HSK F63

- C-Axis with unit interface

- Plate changer 18-fold D=130

- Drilling head 30 spindles: V20 / H10/ S360° "MPU"

- Groove saw: blade-Ø: 200 mm

- Adaptive milling spindle 6 KW for drilling head

- Gluing unit POWER EDGE for 360°-gluing with butt joint

- Flush milling unit for tool changer

Machine Benefits

Qualitative Machine Benefits

- Precision in machining with advanced cnc control, ensuring high-quality finishes

- Flexibility in handling various workpiece sizes and complex operations with the flex-5 unit and power edge gluing system

Technical Machine Benefits

- Combi-flush milling-scraping unit wd 100 mm

- Combi-end trimming and copying unit, traced

- Lock recess milling unit 2 spindles d=16/20

- Chip transport belt for b200/52-72

- Led-setup support console 1300-1600 mm

- Versatile processing capabilities including milling, drilling, gluing, and edge banding

- High-power main spindle and adaptive milling spindle enhance machining efficiency

- Comprehensive tooling options with an 18-fold plate changer and specialized units for specific tasks

Extra Information

Workpiece dimensions:Length max: All units: single field 6,000mm, pendular process 2,375mm. Width max: Frontal all units 1150mm, at milling with tool-diam. 25 mm: 1220mm, at edge banding: 1220mm. Thickness max: 300 mm (inclusive chuck at use as top miller), up to max. 60 mm with standard clamping. Edge material handling capabilities with a height of 105 mm for gluing unit BAZ222/322, allowing edging of workpieces up to 100 mm thickness.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing