Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

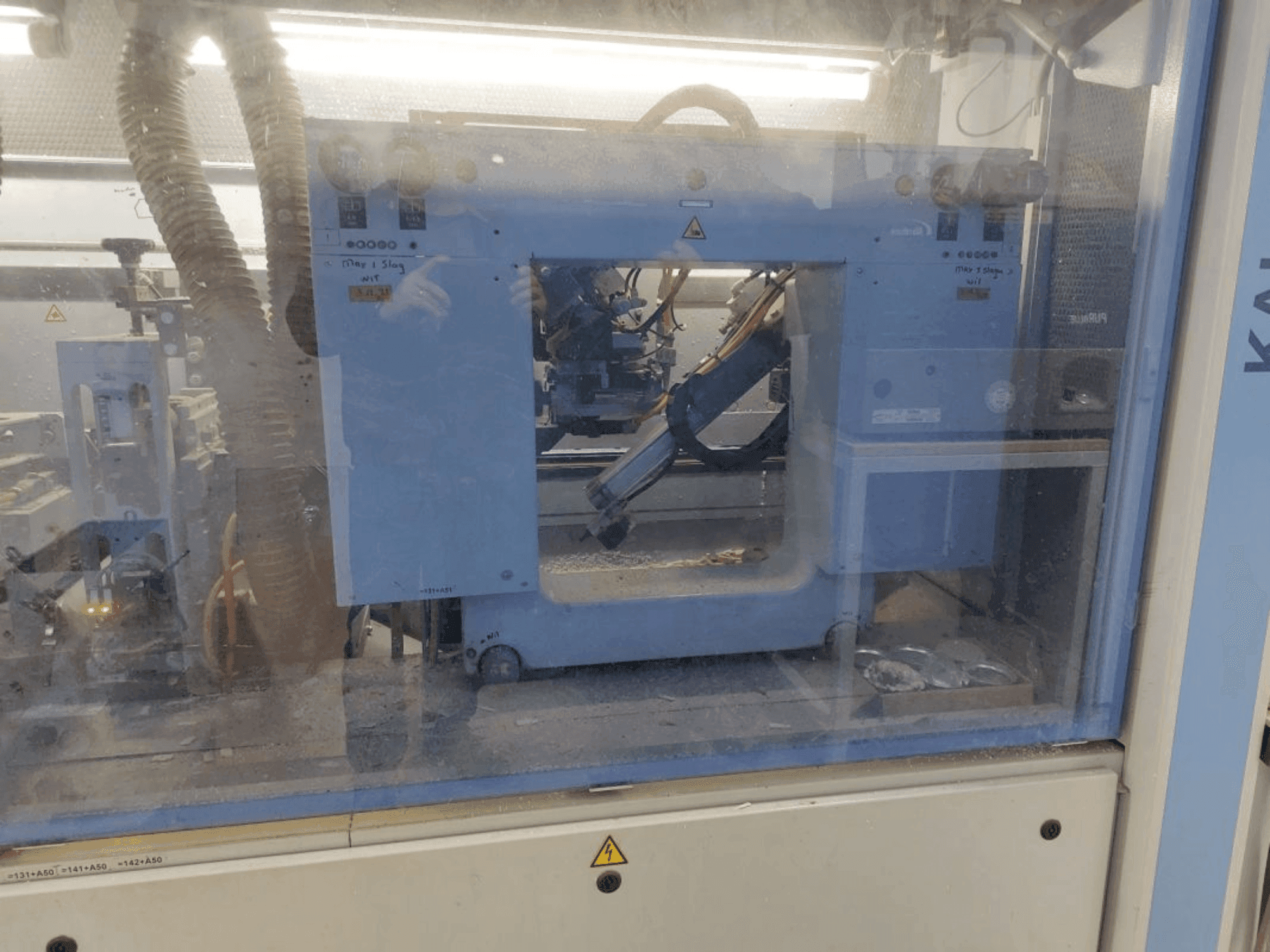

HOMAG - KAL 330/9/A6/LDE-WOO-HOM-2011-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOMAG KAL 330/9/A6/L - 2011 - For Sale

This single-sided edge banding machine machine was manufactured in 2011. A robust and reliable piece of equipment, it features a transport chain with a rubber overlay and a width of 80 mm, ensuring smooth and precise workpiece handling. The machine also boasts an electronically adjustable height setting and a feed rate adjustable up to 25 m/min for optimal performance. A great opportunity to buy this HOMAG KAL 330/9/A6/L film extrusion machine. For more information about this film extrusion machine, please reach out to us.

Overview

- brand: HOMAG

- year: 2011

- MODEL: KAL 330/9/A6/L

- application type: Edge Banding

- Location: Germany

- machine type: Edgebander

Additional Information

Additional equipment

- Basic machine setup

- Adjustable infeed ruler

- Pneumatically controlled infeed lock

- Workpiece transport device

- Gluing unit A20 basic

- Pressure zone C

- Free space for additional processing units

Machine Benefits

Qualitative Machine Benefits

- Magnetically braked transport chain

- Noise protection for joining and aggregate part with individual extraction

- Roll diameter max: 830 mm2

- Edge cross-section max. For strips: 900m2

- Free space for the installation of a joint trimming unit

- Gluing unit a20 basic: workpiece preheating, for heating the edge of the workpiece before glue application and to improve the gluing quality

- Quickmelt application unit: electronic temperature control with led display; glue temperature reduction automatically when work is interrupted (time freely selectable); melting capacity up to max. 12 kg / h ; glue roller drive during feed stop ; glue container lift at feed stop ; glue container clamping workpiece-operated

- Magazine 1 roll: for solid edges, strips and rolls; automatic strip separation via vacuum suction cup; 1 edge feeder; roll separating device; edge monitoring with feed stop; edge sequence control for preselecting the edge channels in any sequence. If an edge channel is empty, the next selected channel is activated (with multiple magazine)

- Pressure zone c: 1 driven pre-press roller diameter 150 mm; 6 holding rollers diameter 70 mm; pneumatic pressure adjustment; central adjustment to different edge thicknesses

- Electrical equipment: - operating voltage 400 volt, 50/60hz - mounted switch cabinet - installed in accordance with european standard en 60204 - electronic frequency converter with motor braking function - country-specific operating voltage adjustment via transformer (optional) - rcd protection circuit only permissible in conjunction with an all-current sensitive/selective rcd. If the performance of this device is not sufficient, we recommend using a residual current monitoring device on site - prescribed ambient temperature: + 10 to + 40 ° c

Technical Machine Benefits

- Transport chain with rubber pad, 80 mm wide

- Workpiece support with roller rail, extendable by approx. 800 mm

- Feed rate: 18 m/min (optional; 18-25 / 18-32 m/min)

- Working height: 950 mm

- Pneumatic connection: 6 bar

- Workpiece thickness: 12-22 mm-60 mm, 23-60 mm-100 mm

- Workpiece stock: 30 mm

- Workpiece thickness: 12-60 mm

- Edge material roll: 0. 3-3 mm2

- Edge cross-section max: for pvc: 135 mm2. For veneer: 100 mm2

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing