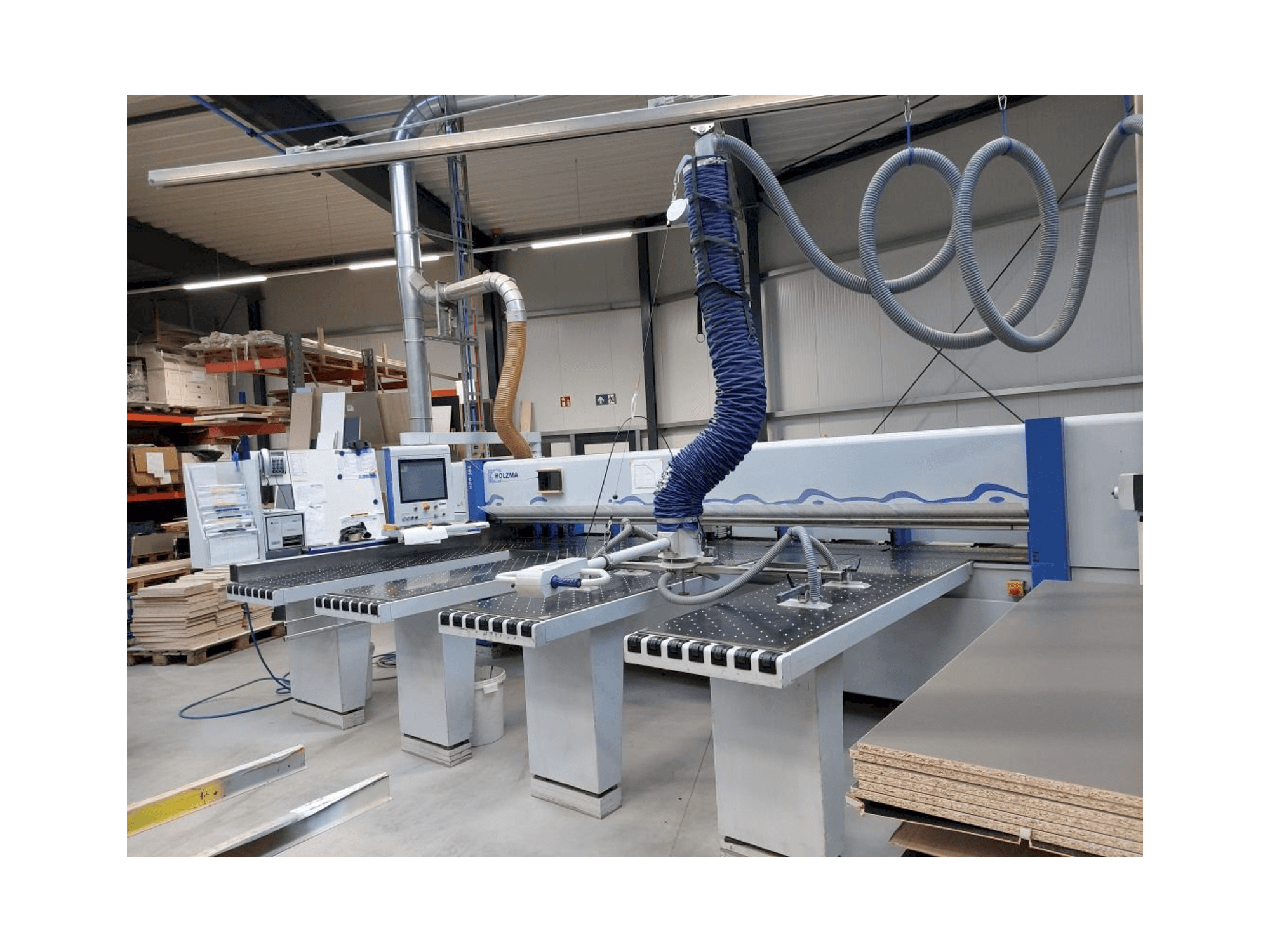

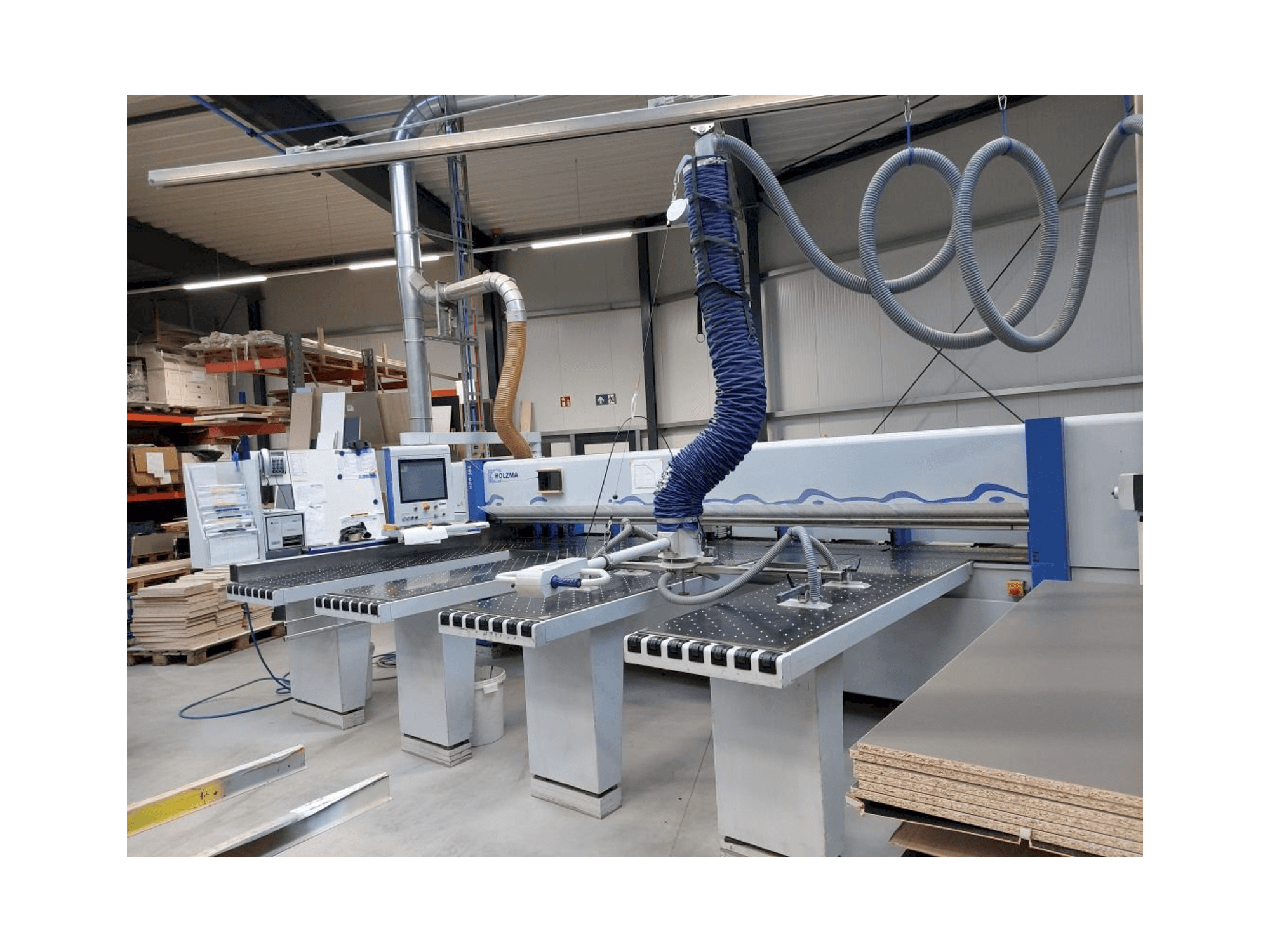

HOLZMA - HPP 380DE-SAW-HOL-2007-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used HOLZMA HPP 380 - 2007 - Saw For Sale | gindumac.com

This HOLZMA HPP 380 panel saw was manufactured in 2007. It features a robust steel saw carriage, main and pre-cut saws, and a patented Central Angle Return Device that reduces cycle time by up to 25%. The machine is equipped with a Power Control CADmatic 4 system, ensuring precise and efficient operation. The saw blade projection is 95 mm, and it operates with a main saw motor of 18.0 kW. For more information about this panel saw, please reach out to us.

Overview

- brand: HOLZMA

- year: 2007

- MODEL: HPP 380

- application type: Sawing (Wood)

- Location: Germany

- machine type: Panel Saw

Technical Information - HOLZMA HPP 380

Control Unit

- Control Model: CADmatic 4 - Professional

Additional Information

Additional equipment

- Air cushion table with roller element 2160 x 650 mm: 4 pieces

- Central blower: 1 piece

Machine Benefits

Qualitative Machine Benefits

- Ce-certified, gs-certified, fph wood dust certified

- Division: 75/275/475/1050/1850/2650/3450 mm measured from the angle rule to the center of the clamping collet

- 2 additional two-fingered clamping collets possible

- 4 manual trimming rakes at clamping collets

- 1 additional one-fingered clamping collet possible

- Jet spacing of air cushion tables: 70 x 70 mm

Technical Machine Benefits

- Pre-cut saw motor: 2. 2 kw

- Operating voltage: 400 v / 50 hz

- Electrical connection value at hs motor: 18. 0 kw = 24 kw, 21. 0 kw = 27 kw

- Positioning accuracy: +/- 0. 1 mm/m

- Surface-friendly material transport, lifetime positioning accuracy, no lubrication required, high program slider speed, maintenance-free, full stability of the steel table maintained, easy, cost-effective replacement of phenolic resin plates, minimal wear of the cylinders, uniform pressure application, minimal cutting = scratch cut, significant cycle time savings, top cutting quality, minimal setup times, reduction of cycle time, pressure strength electrically adjustable

- Cutting length: 4300 mm

- Cutting width (program slider travel): 4250 mm

- Roller track (element 10-track): 1 piece

- Roller track (element 2-track): 5 pieces

- Clamping collets: 7 pieces (first 3 pieces two-fingered, all others one-fingered)

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing