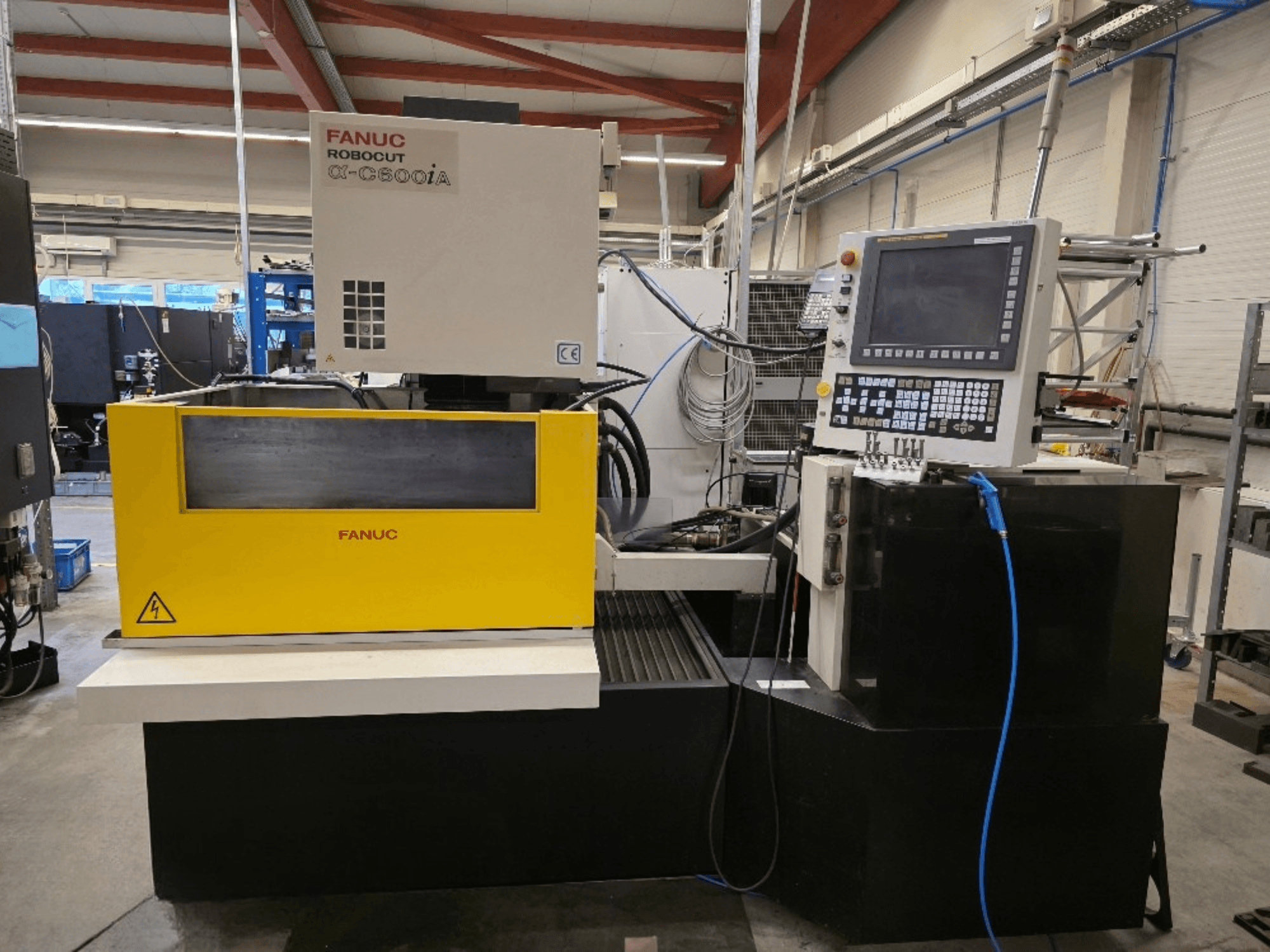

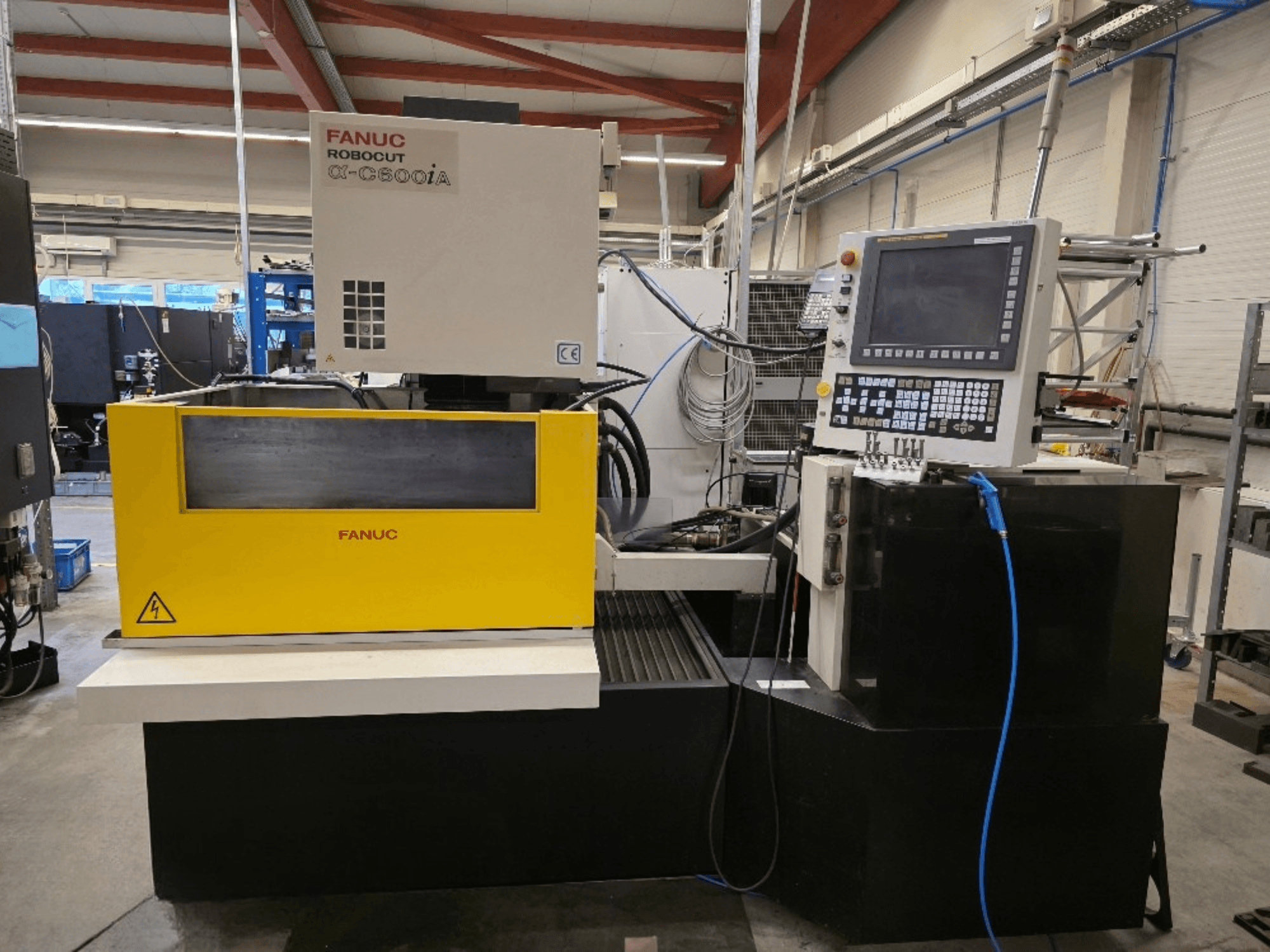

FANUC - RoboCut alpha C600iAHU-EDM-FAN-2015-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used FANUC RoboCut alpha C600iA For Sale | gindumac.com

This 5-axis FANUC RoboCut alpha C600iA was manufactured in 2015, featuring X/Y axis travel of 600 mm × 400 mm and a Z-axis option up to 410 mm. It supports a maximum workpiece weight of 1000 kg and utilizes a FANUC Series 31i-W MODEL B CNC for precise control. Equipped with AI technology for enhanced accuracy and automatic wire threading, it's ideal for detailed machining tasks. Consider the opportunity to buy this FANUC RoboCut alpha C600iA wire edm machine. Contact us for more information.

Overview

- brand: FANUC

- year: 2015

- MODEL: RoboCut alpha C600iA

- application type: EDM

- Location: Hungary

- machine type: Wire EDM Machine

- control unit brand: FANUC

Technical Information - FANUC RoboCut alpha C600iA

Control Unit

- Control Brand: FANUC

- Control Model: RoboCut α-C600iA

Dimensions

- Machine Weight: 3000 kg

Movement

- Number of Axes: 5

- X-axis Travel: 600 mm

- Y-axis Travel: 400 mm

- Z-axis Travel: 310 mm

Technical Specification

- Max. Wire Diameter: 0.3 mm

- Min. Wire Diameter: 0.1 mm

Additional Information

Axis travels: X/Y 600 × 400 mm; Z 310 mm (optional 410 mm); U/V ±100 × ±100 mm

Max workpiece size: 1050 × 800 × 310 mm (standard)

Max workpiece weight: 1000 kg

Max taper angle: ±30° at 150 mm (optional ±45° at 70 mm)

Positioning/minimum step size: 0.0001 mm

Achievable surface roughness: up to Ra 0.3 µm

Automatic wire threading (AWF): approx. 10 s under water; rethreading inside submerged cuts

AI Corner Control: optimizes cutting speed and flushing in sharp corners

ECO Mode: energy and wire consumption reduction functions

Applications/materials: steel, aluminum, titanium, nickel alloys; mold & die, aerospace, medical, precision parts

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing