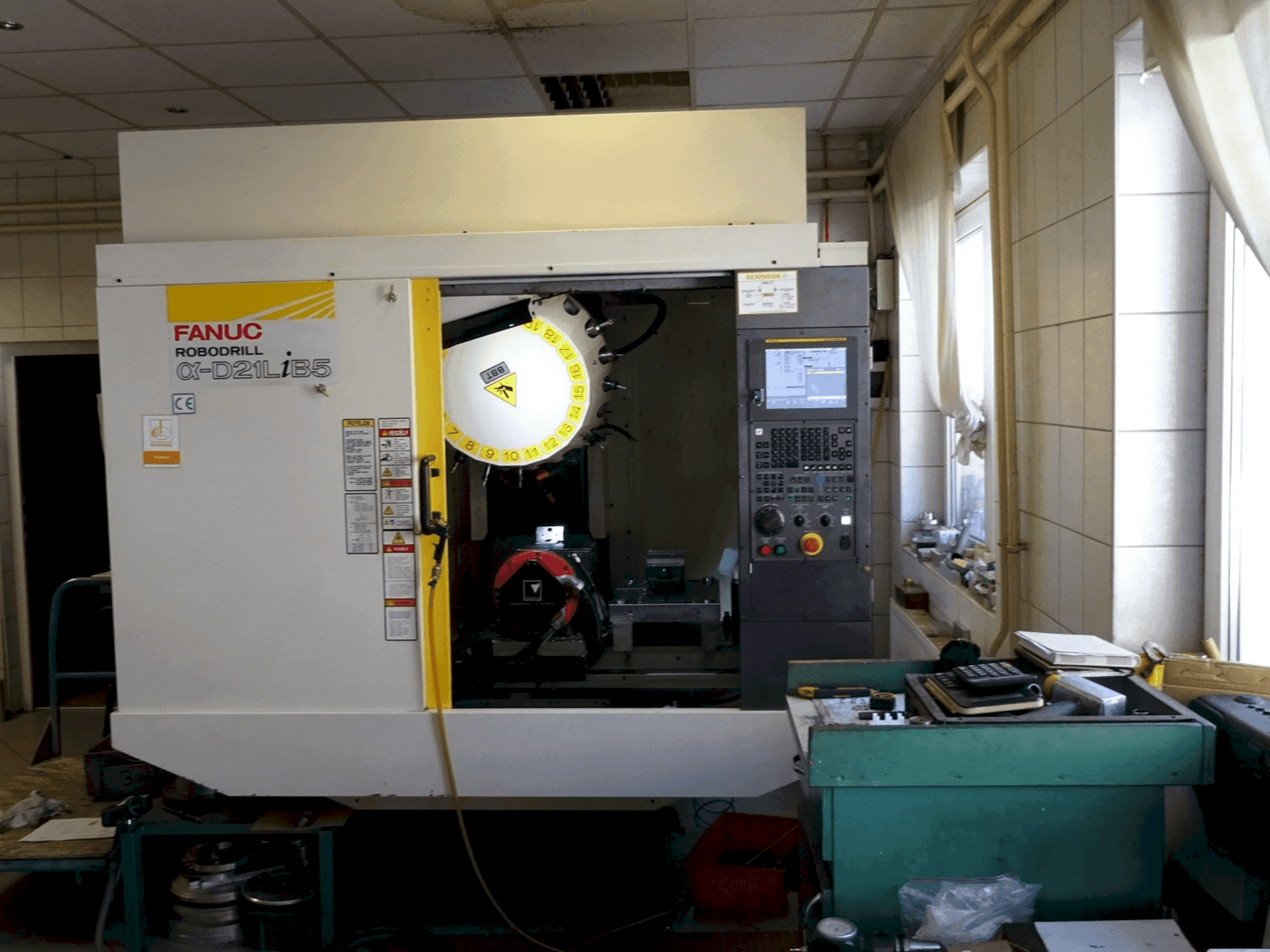

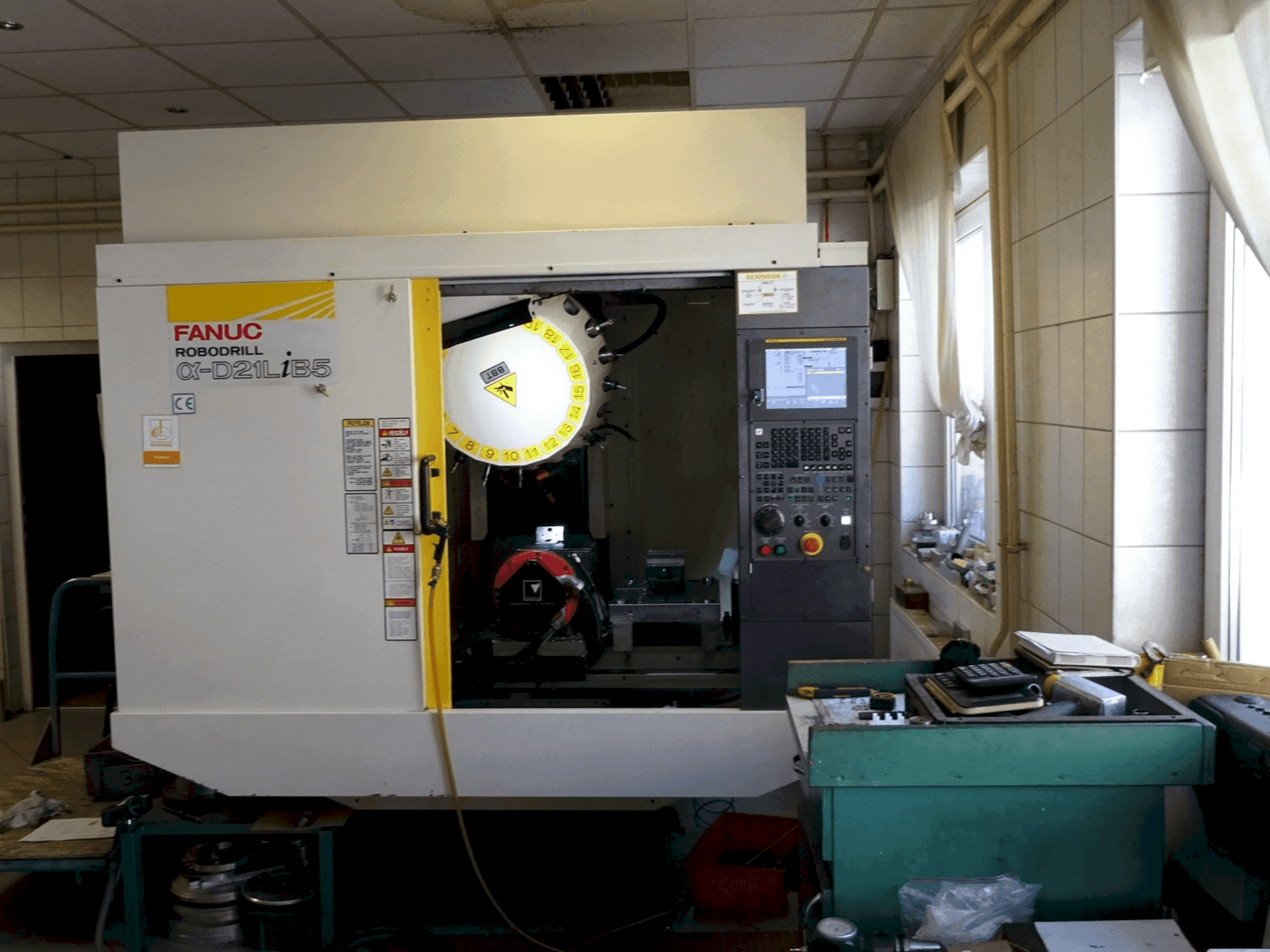

FANUC - Alfa D21LiB5HU-MIL-FAN-2018-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used FANUC Alfa D21LiB5 For Sale | gindumac.com

This 5-axis FANUC Alfa D21LiB5 was manufactured in 2018 and features a robust vertical machining center design. Key specifications include a travel range of 700 × 400 × 330 mm, a table size of 850 × 410 mm, and a maximum table load of 300 kg. It supports a spindle speed of up to 24,000 rpm and a rapid traverse in all axes at 54 m/min. Consider the opportunity to buy this FANUC Alfa D21LiB5 vertical machining center. Contact us for more information.

Overview

- brand: FANUC

- year: 2018

- MODEL: Alfa D21LiB5

- application type: Milling

- Location: Hungary

- machine type: Vertical Machining Centre

- control unit brand: FANUC

Technical Information - FANUC Alfa D21LiB5

Control Unit

- Control Brand: FANUC

- Control Model: 31i-B5

Dimensions

- Table Load: 300 kg

Movement

- Number of Axes: 5

- X-axis Travel: 700 mm

- Y-axis Travel: 400 mm

- Z-axis Travel: 330 mm

Technical Specification

- Max. Tool Weight: 3 kg

- Spindle Speed: 24000 RPM

Additional Information

Table size: 850 × 410 mm

Distance from spindle nose to table (with HC100): 250–580 mm

Spindle load at 10,000 rpm (1 min): 80 Nm / 14.2 kW

Spindle load at 10,000 rpm (continuous): 13.6 Nm / 4 kW

Spindle load at 24,000 rpm (1 min): 35 Nm / 26 kW

Spindle load at 24,000 rpm (continuous): 7.5 Nm / 5.5 kW

Programmable cutting feed: 30,000 mm/min

Acceleration X/Y/Z (100 kg table load, 2 kg tool): 1.4G / 1.0G / 1.6G

Tool change time (2 kg tool), cut-to-cut: 1.6 s

Bidirectional positioning accuracy (ISO 230‑2:1988): ≤ 0.006 mm

Bidirectional positioning repeatability (ISO 230‑2:1997, 2006): ≤ 0.004 mm

Air consumption: 150 L/min at 0.35–0.55 MPa

Machine mass / with DDR‑T: 2.1 / 2.3 t

Additional equipment

NOT INCLUDED IN THE PRICE

Approx. 40 tool holder cones (including original tool holder cones)

2 torque tapping heads with cones

3 drill chucks with cones

1 three‑dimensional probe with cone

4–5 milling heads

Ground precision vise

5‑axis ground vise with raised jaws

Three‑jaw chuck, 160 mm

Four‑jaw chuck, 160 mm

Set of parallels

Sets of collets in different sizes

Stands, measuring instruments, gauges, etc.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to FANUC Alfa D21LiB5

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

VF 2 SS

HAAS - Vertical Machining Centre

EC-400

HAAS - Horizontal Machining Centre

A61-5XR

Makino - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre

PICOMAX 55 CNC 2/3

FEHLMANN - Vertical Machining Centre

C 800 V

HERMLE - Vertical Machining Centre