Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

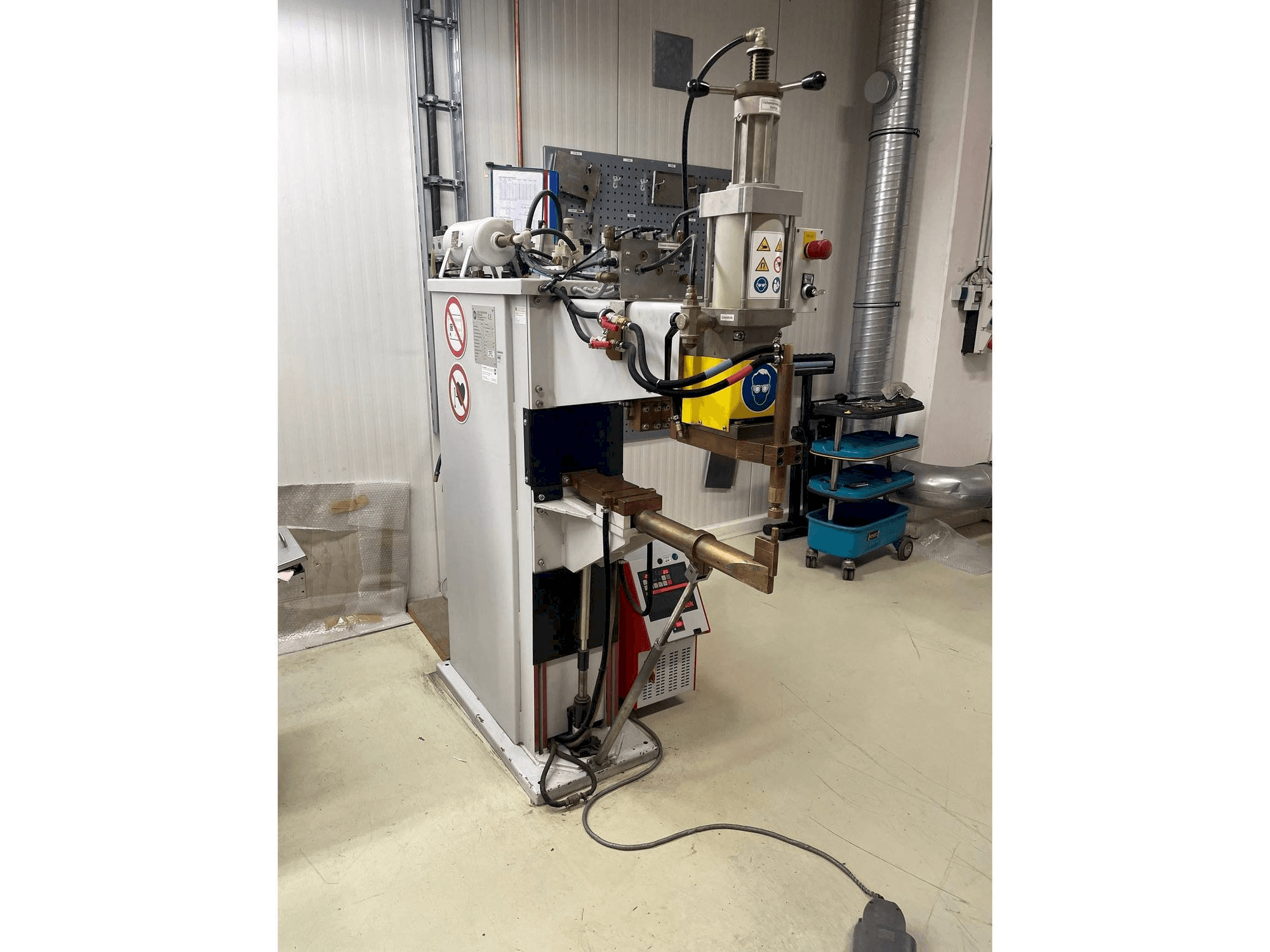

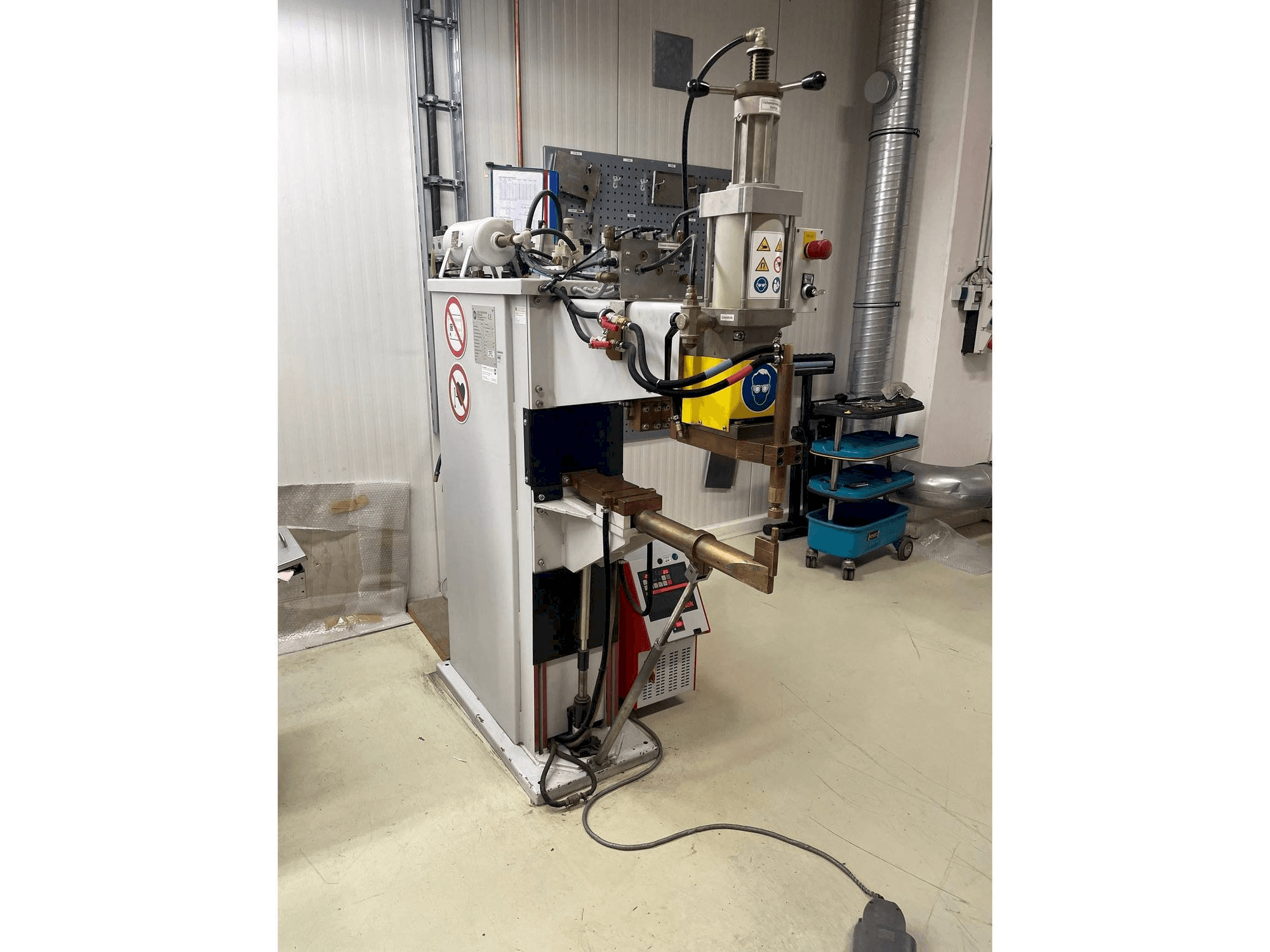

EST - 8212 SDE-WEL-EST-2004-00001

Sold

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

Click to chat on WhatsApp

- GINDUMAC

- Products

- Sheet Metal Machinery

- EST 8212 S Welding machine

Show in original language

This EST 8212 S Welding machine was manufactured in the year 2004 in Germany. It is equipped with a TE500 control unit. See tech specs PDF (German) attached for more details.

Overview

- brand: EST

- year: 2004

- MODEL: 8212 S

- application type: Welding

- Location: Germany

- machine type: Laser Welding Machine

Additional Information

Machine Benefits

Qualitative Machine Benefits

- Proportional valve for working pressure (set/actual value adjustment with pressure monitoring)

- Pressure tank to compensate for mains fluctuations

- Pre-stroke controlled via key switch

- Lower console height-adjustable by means of lifting device

- T-slot plates top / bottom width 120mm, slot spacing 63mm for slot stone m12

- Solenoid valve for shutting off the cooling water and water flow monitor (flow control switch)

- Rs 232 interface

- Interface for proportional valve

- 2-stage foot switch (start 1)

- Second welding programme can be called up via optional 2nd foot switch

Technical Machine Benefits

- Welding cylinder with 736 dan at 6 bar to provide the necessary electrode force (double lifting cylinder with chrome steel wall and torsion protection)

- Adjusting device for welding cylinder

- Back pressure, lowering the electrode at low pressure, adjustable via precision pressure regulator

- Lowering the cylinder without pressure for set-up and maintenance work

- Emergency stop switch and emergency stop main machine switch

- Additional tubular electrode arm with indirectly cooled bar and finger electrode

- Lower console 99001-03. 01 (d=270/ d=120/ =x 465) lower arm support

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Your account manager:

Borja Garcia

Borja Garcia is one of our used machinery trading experts and will be your direct contact for any further questions on the machine. Feel free to contact him/her.

Payment Terms

Payment in advance

Asset Financing