Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

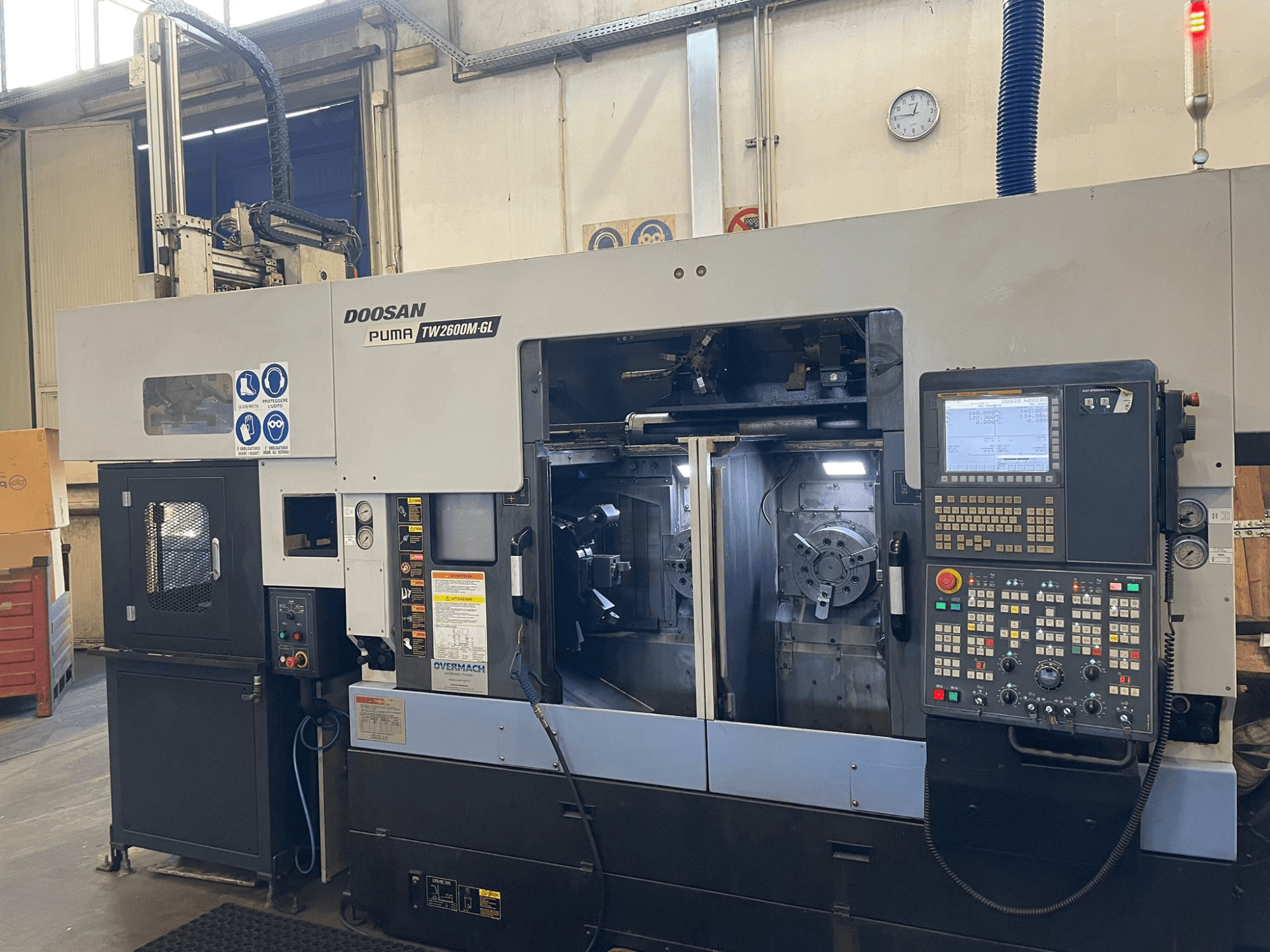

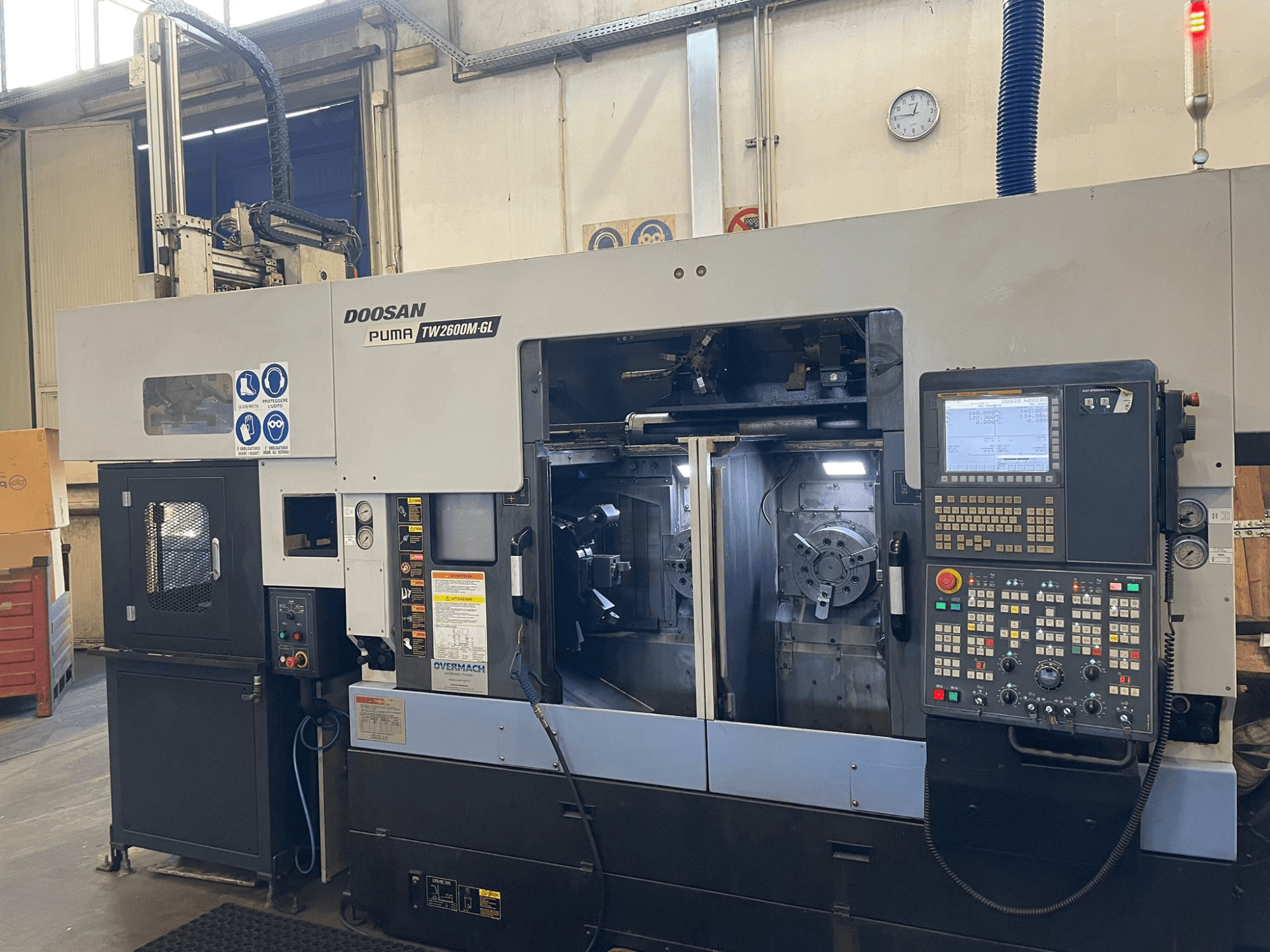

DOOSAN - TW2600 M-GL IT-TUR-DOO-2017-00006

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DOOSAN TW2600 M-GL For Sale | gindumac.com

This 3-axis DOOSAN TW2600 M-GL was manufactured in 2017. A CNC Twin-Spindle Turning Center featuring a Gantry Loader and Driven Tools, it offers a max turning diameter of Ø 350 mm and a length up to 274 mm. Equipped with a high-pressure coolant system, chip conveyor, and a dual chuck configuration, it ensures efficient operations. If you are looking to get high-quality turning capabilities consider the DOOSAN TW2600 M-GL machine we have for sale. Contact us for more information.

Overview

- brand: DOOSAN

- year: 2017

- MODEL: TW2600 M-GL

- application type: Turning

- Location: Italy

- machine type: Horizontal Turning Machine

Technical Information - DOOSAN TW2600 M-GL

Dimensions

- Machine Weight: 7800 kg

Movement

- Number of Axes: 3

Technical Specification

- Spindle Speed: 3500 RPM

Additional Information

Control: Doosan-Fanuc i-Series (Digital FANUC, Manual Guide i, extended memory 512+512 KB, Ethernet, RS-232C, USB, rigid tapping, tool offset memory, feed rate override)

Construction: Cast iron bed, twin separated structure (left/right), 0° inclination

Spindles and Capacity

Spindle nose: ASA A2-6

Chuck diameter: Ø 255 mm (dual chuck configuration)

Bar capacity: Ø 66 mm

Max turning diameter: Ø 350 mm

Max turning length: 245 / 274 mm

C1/C2 axis positioning accuracy: ±0.001° (hydraulic indexing)

Distance between spindle centers: 450 mm

Max load per spindle: 260 kg

Axes and Feeds

Travels: X1/X2 = 190 mm; Z1/Z2 = 410 mm; C1/C2 = 360°

Rapid traverse (X1/Z1, X2/Z2): 24 / 24 m/min

Cutting feed (X1/Z1, X2/Z2): 12 / 12 m/min

Rotary axis feed (C1/C2): 33 rpm

Turrets

Right turret: BMT-55P motorized turret, 12 stations (all driven), max tool speed 5,000 rpm, driven tool motor 5.5 / 3.7 kW

Tooling interface: Tool shank 25 × 25 mm; boring bar Ø 40 mm

Indexing: 0.2 s per station, servo indexing with hydraulic clamping

Additional equipment

Gantry loader Type A1:

Loading capacity: max 6 kg

Part diameter: Ø 25 to Ø 125 mm

Part length: 20–100 mm

Axis strokes (X/Y/Z): 710 / 215 / 220 mm

Typical load/unload cycle time: 9 s

Operating air pressure: 5–6 bar

Parts magazine (recirculating pallet system, A1 type):

Number of pallets: 14

Max pieces per pallet: 15

Total capacity: up to 210 pieces

Tooling package for both turrets:

Axial toolholders: 3 + 3

Radial toolholders: 1 + 1

Driven toolholders: 2 + 2

Reduction sleeves: ER-25, Ø 25 mm

High-pressure coolant system

Chip conveyor and splash guard

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing