Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

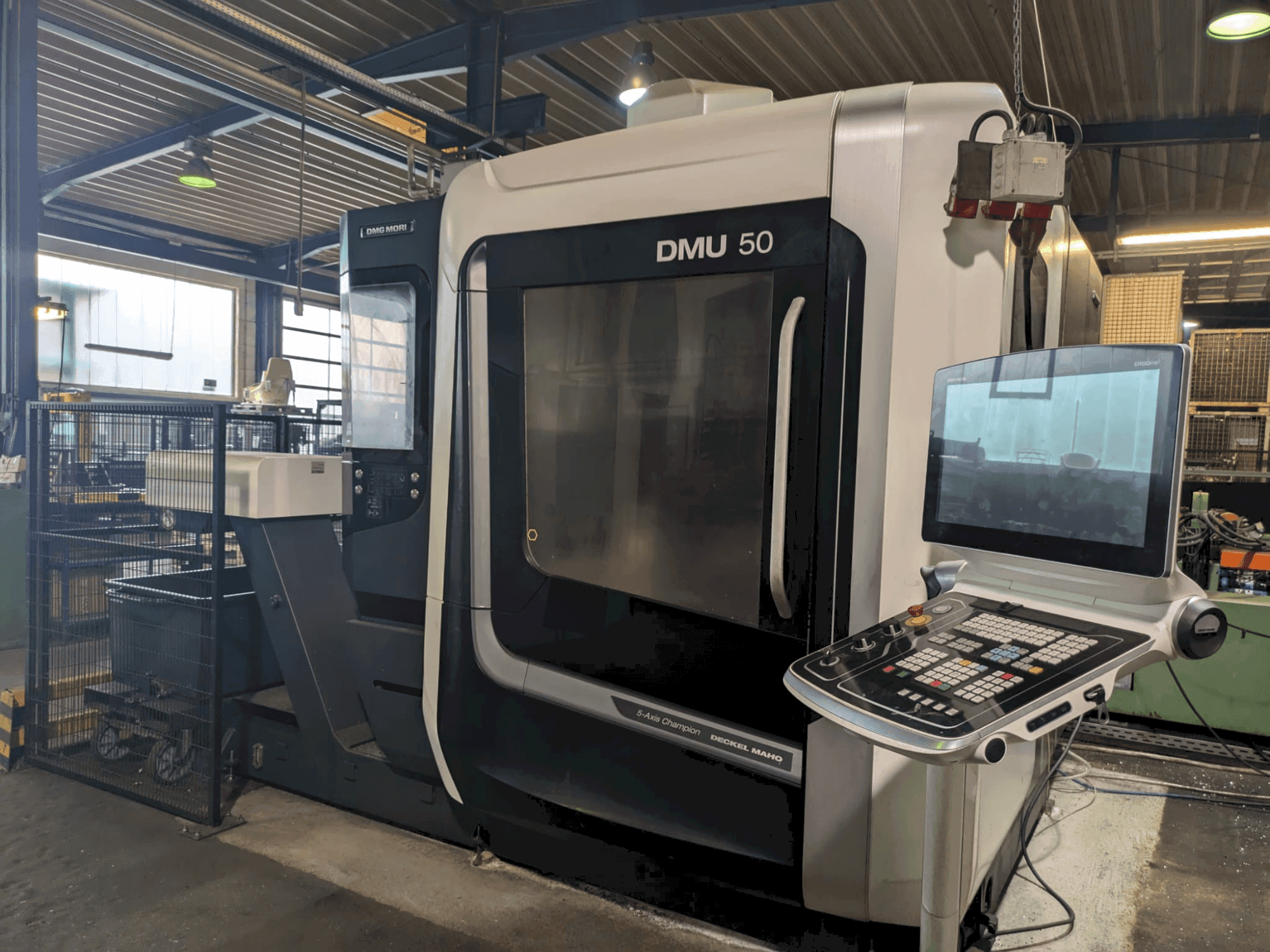

DMG MORI - DMU 50 3rd GenDE-MIL-DMG-2018-00005

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used DMG MORI DMU 50 3rd Gen For Sale | gindumac.com

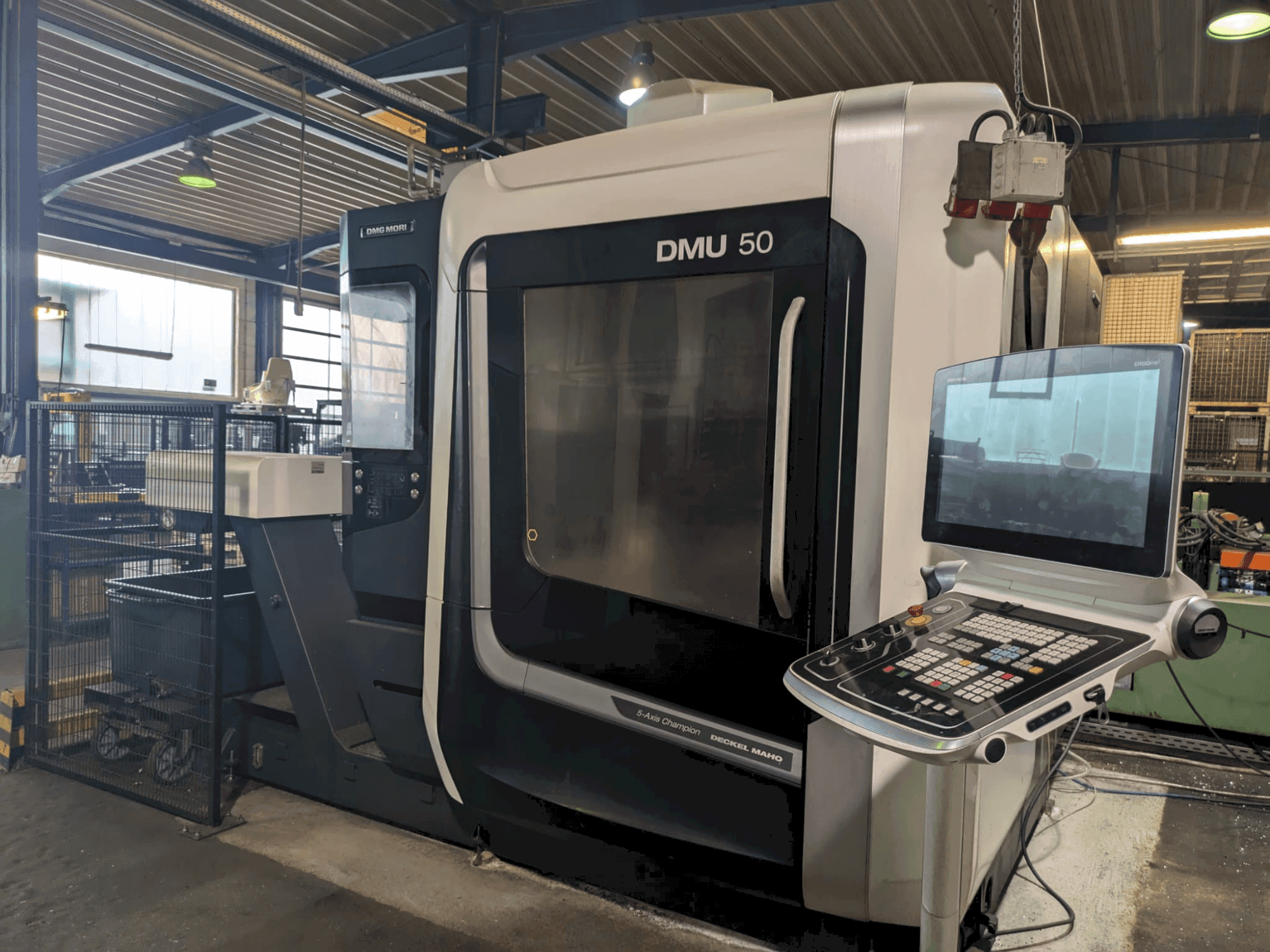

This 5-axis DMG MORI DMU 50 3rd Gen was manufactured in 2018. It features a spindle speed up to 15,000 min−1, a 30-place SK40 tool changer, and a CELOS control system with Siemens 840D sl Operate. The machine includes a swivel rotary table with a clamping surface of D630 x 500 mm and a 360° rotary axis. Consider the opportunity to buy this DMG MORI DMU 50 3rd Gen vertical machining centre. Contact us for more information.

Overview

- brand: DMG MORI

- year: 2018

- MODEL: DMU 50 3rd Gen

- production hours: 1843

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - DMG MORI DMU 50 3rd Gen

Control Unit

- Control Brand: SIEMENS

Dimensions

- Machine Weight: 2600 kg

Movement

- Number of Axes: 5

- X-axis Travel: 650 mm

- Y-axis Travel: 520 mm

- Z-axis Travel: 475 mm

Technical Specification

- Spindle Speed: 15000 RPM

Additional Information

Tool changer: 30 stations SK40 with setup assistance

Control: CELOS with Siemens 840D sl Operate, 21.5" ERGOline multi-touch

Measuring system: Direct path measuring on X, Y, Z, B, C axes

Swivel rotary table (NC), simultaneous capability

Clamping surface: Ø630 x 500 mm

B-axis swivel range: −35° to +110°

C-axis rotation: 360°

Cooling/working area features:

Active spindle cooler

Coolant/blow-air switchover via M-function

Working area flushing

Safety/options on machine:

Half cabin

MPC Machine Protection Control (quick shutdown)

Preparation for 3D quickSET toolkit (software option included)

Additional equipment (accessories)

Scraper-type chip conveyor (not suitable for unmanned operation)

Internal coolant supply (IKZ): paper band filter, 40 bar / 23 l/min, 600 l tank

Oil and emulsion mist separator (mechanical)

Infrared measuring probe: Heidenhain TS 649 DMG

Tool preset device (available as an option)

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to DMG MORI DMU 50 3rd Gen

VMX 60

Hurco - Vertical Machining Centre

CMX 70U

DMG MORI - Universal Machining Centre

VF 2 SS

HAAS - Vertical Machining Centre

EC-400

HAAS - Horizontal Machining Centre

ACE HP 4000

DAEWOO - Vertical Machining Centre

V85

MTcut - Vertical Machining Centre

MCPH150 UNIPRO 90

HELLER - Horizontal Machining Centre

DMC-63V

DECKEL - Vertical Machining Centre

DMC 60T

DMG DECKEL MAHO - Universal Machining Centre

PICOMAX 55 CNC 2/3

FEHLMANN - Vertical Machining Centre

C 800 V

HERMLE - Vertical Machining Centre

VCN 700E/40-II

Mazak - Vertical Machining Centre