Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

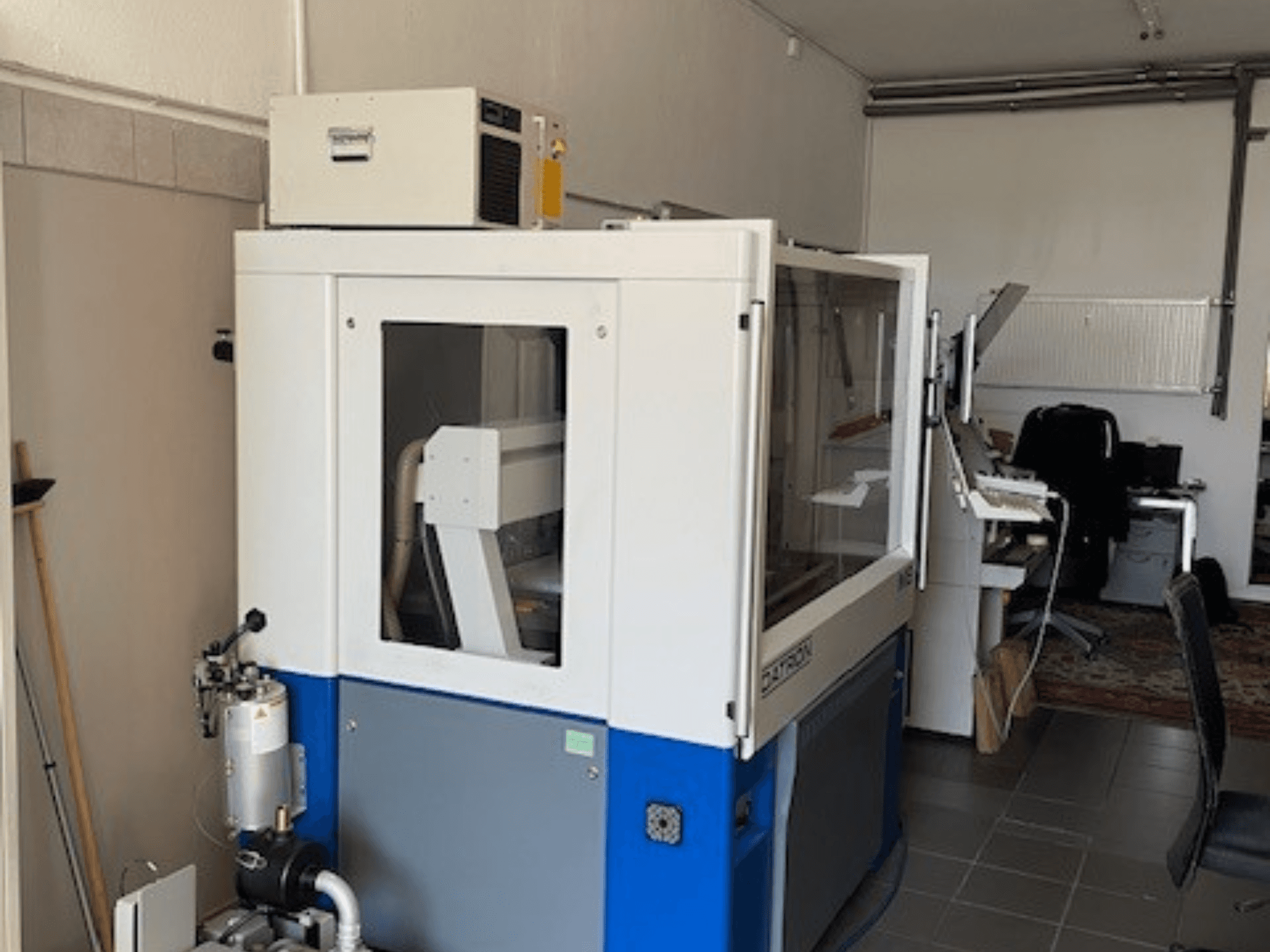

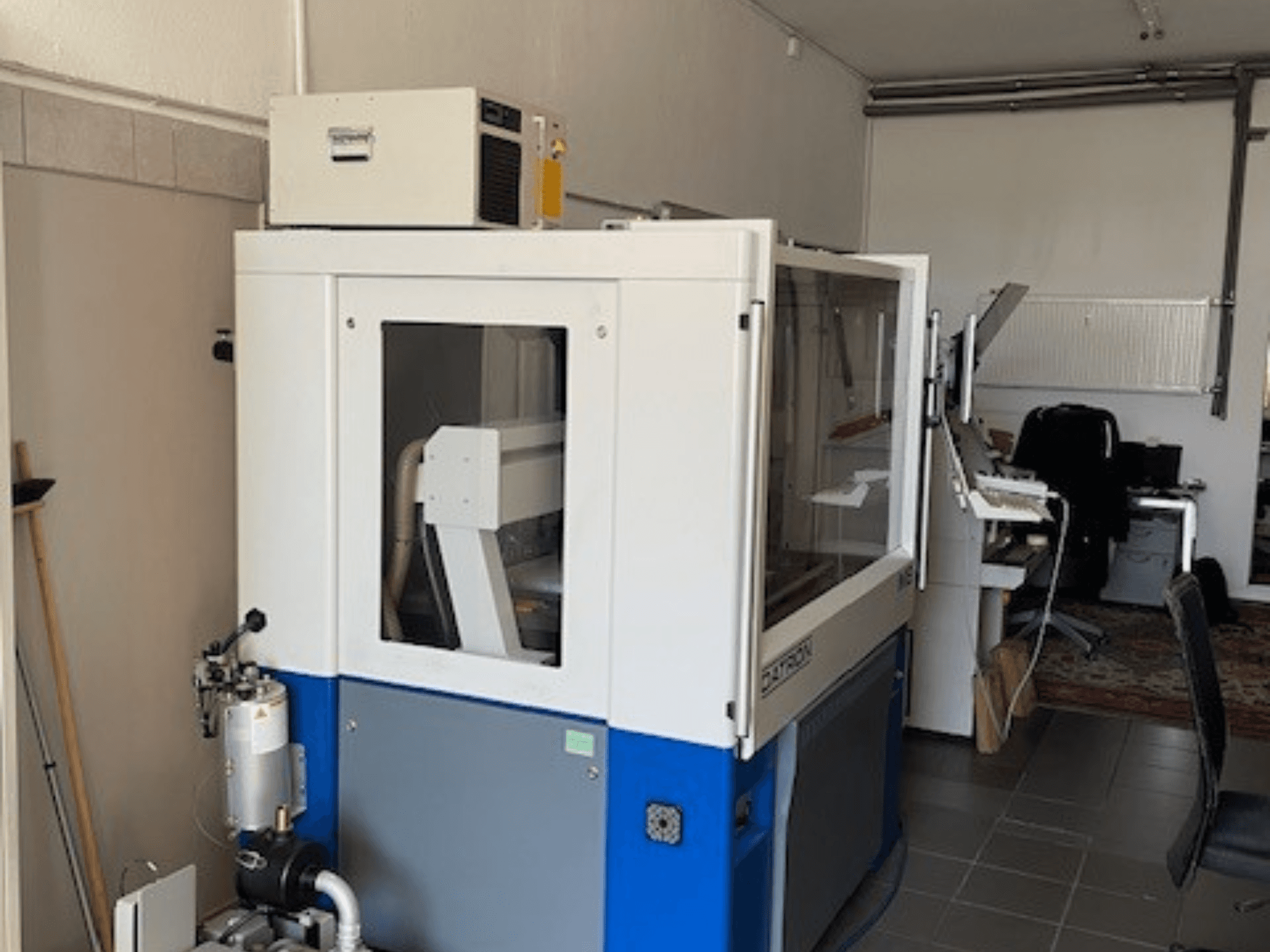

Datron - M8DE-MIL-DAT-2011-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used Datron M8 Machining Center For Sale | gindumac.com

This 3-axis Datron M8 vertical machining center was manufactured in 2011. It features a robust gantry design with double-supported drives and precision guideways. Key specifications include a 2.0 kW SF spindle with speeds up to 60,000 rpm, a 15-position tool changer, and a travel range of 1020 mm x 800 mm x 240 mm. Ideal for detailed and precise machining tasks. Contact us for more information about this machine.

Overview

- brand: Datron

- year: 2011

- MODEL: M8

- production hours: 50

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

Technical Information - Datron M8

Dimensions

- Machine Height: 1950 mm

- Machine Length: 1850 mm

- Machine Weight: 915 kg

Movement

- Number of Axes: 3

- X-axis Travel: 1020 mm

- Y-axis Travel: 800 mm

- Z-axis Travel: 240 mm

Additional Information

Configuration: SF spindle 2.0 kW HighS H2.0 (up to 60,000 rpm), direct-switching

Tool holding: Direct clamping, max Ø 8 mm; 6 mm collet

Tool changer: 15-position with length sensor, direct clamping

Machine design: Gantry design with double-supported drives; solid polymer concrete on steel frame; precision guideways

Table: Coordinate table (without cutout)

Travels: X 1020 mm, Y 800 mm, Z 240 mm; gantry spacing 200 mm

Drives: Digital servo drives; ball screw per axis

Feed rate: up to 20 m/min

Control: DATRON 3D-CNC control V9; LCD/control computer with keyboard and 19" monitor (integrated CD drive)

Cooling/Lubrication: DATRON cooling spray system; spindle cooler type H-K GK; speed option for SF spindle

Additional equipment

Probing/sensors:

XYZ sensor (complete with swivel arm, operating materials, mounting), feature: full software control

Z-axis TP-D sensor

Z-axis height sensor

Clamping technology:

Vacuum module clamping plate 650 x 450 x 40 mm, 3 connections (approx. 27 kg); accessories: VakuCard, VakuCardMatt

T-slot module clamping plate 460 x 250 x 83 mm (250 x 460 x 80 nominal), with fixed jaw, 2 rows, 450 Type B; includes centering bushing and seal; accessories: short-stroke clamping elements

Short-stroke clamping element, pneumatic-hydraulic, Type KSE-PH (130 x 110 x 65 mm, 1.6 kg; operating pressure 1–8 bar; stroke 7 mm; clamping force up to 3,200 N); includes compressed air hose; accessory: fixed clamping jaw

Vacuum system:

Vacuum distributor 3-way V V-3 with shut-off valves (incl. additional shut-off with vent), vacuum gauge, through-wall fitting, hoses, and complete mounting hardware

Vacuum pump Type VP-B-1, rotary vane, oil sump lubrication; suction capacity 100 m³/h; ultimate pressure 20 mbar; motor 3.0 kW; 3 x 400 V; sound pressure level 67 dB(A); dimensions 748 x 433 x 310 mm; weight 70 kg; oil capacity 2 l; includes three-phase contactor, rotary valve, differential pressure switch, vacuum reservoir, motor protection switch, oil monitoring, intake filter, and three-phase contactor

Clamping surface capability up to 1,000 x 1,500 mm

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing