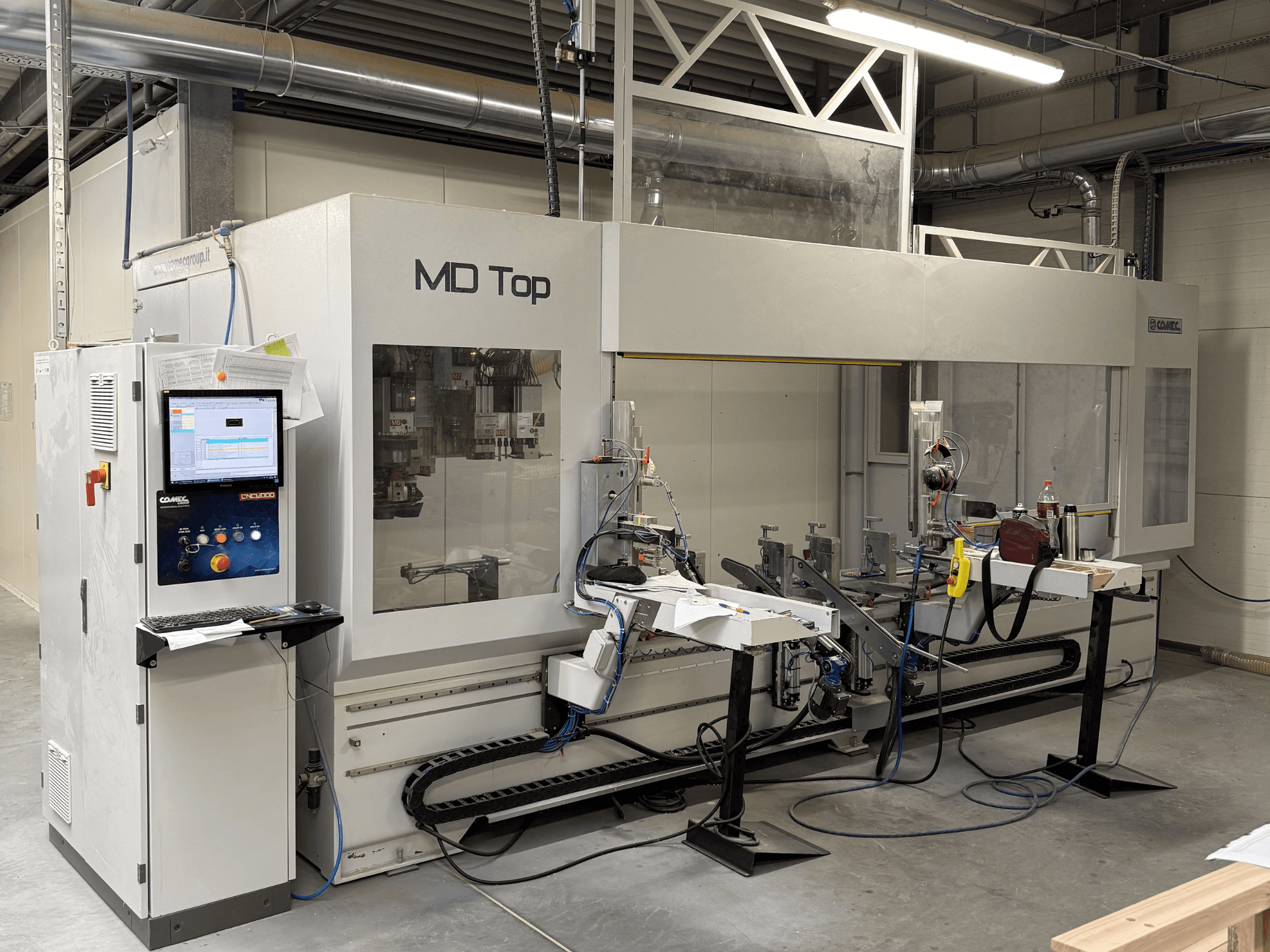

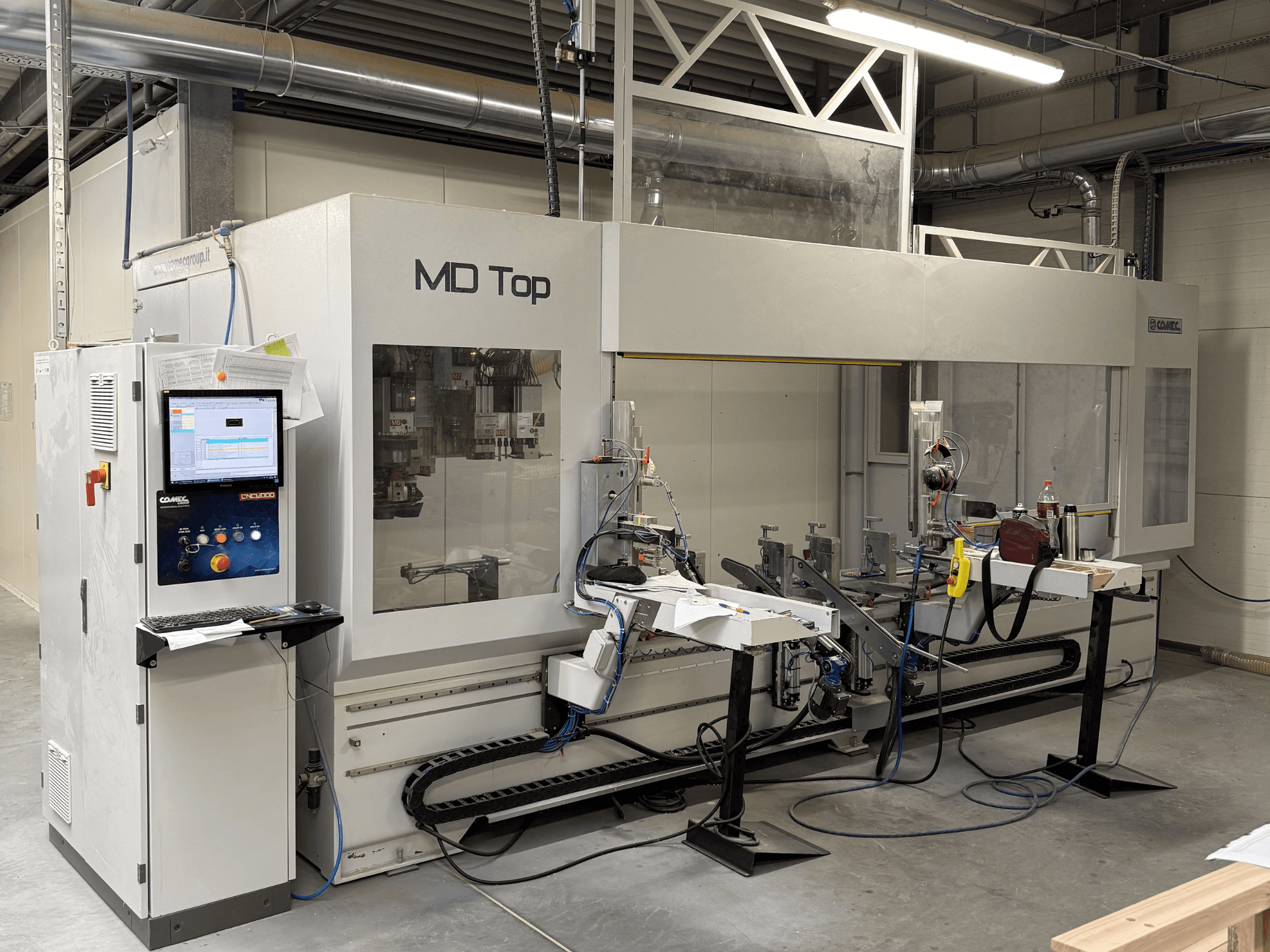

COMEC - MD TOP XLPL-CNC-COM-2020-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Wood Working

- ➤ Used COMEC MD TOP XL - 2020 - For Sale | gindumac.com

This 3-axis COMEC MD TOP XL CNC Wood Machining Centre was manufactured in 2020. It features a robust mono-block structure, high-speed axes positioning up to 70 m/min, and versatile electro-spindles for drilling, milling, and cutting. The machine includes a CAD-CAM control unit with a 17" touchscreen and full safety enclosures. If you are looking to get high-quality woodworking capabilities, consider the COMEC MD TOP XL machine we have for sale. Contact us for more information.

Overview

- brand: COMEC

- year: 2020

- MODEL: MD TOP XL

- application type: CNC Wood Machining

- Location: Poland

- machine type: CNC Wood Machining Centre

Technical Information - COMEC MD TOP XL

Movement

- Number of Axes: 3

- X-axis Travel: 3350 mm

- Y-axis Travel: 200 mm

- Z-axis Travel: 180 mm

Technical Specification

- Spindle Power: 5.6 kW

- Spindle Speed: 18000 RPM

Additional Information

Machine frame: Heavy-duty mono-block structure in electro-welded steel

Spindles:

Vertical electro-spindles: 3

Drilling spindle

Power: 1.7 kW

Speed: 4350 rpm

Point-to-point drilling head:

5 vertical drilling spindles (32 mm spacing)

3 double-exit horizontal spindles along Y-axis (32 mm)

3 double-exit horizontal spindles along X-axis (32 mm)

Milling/mortising spindle

Power: 7.0 kW

Speed range: 12,000–18,000 rpm

Cutting/milling/drilling spindle

Power: 7.0 kW

Speed range: 8,000–18,000 rpm

Multi-function aggregate included

Horizontal electro-spindle:

Type: Milling/mortising spindle

Power: 5.6 kW

Speed: 12,000–18,000 rpm

Tool holder: ER32 collet

Working area:

Nominal strokes: X 3350 mm, Y 200 mm, Z 180 mm

Two working fields: 2 × 1500 mm

Axes positioning speed: up to 70 m/min

Interpolation: Linear and circular on X/Y/Z (3 axes CN-controlled)

Workpiece support tables:

4 + 4 tables on adjustable slides

Each table with 4 + 4 vertical pneumatic clamping cylinders

Frontal and lateral reference stops

Control system:

CAD-CAM control unit

Stand-alone electrical cabinet

Industrial PC with 17" touchscreen

Connectivity: Ethernet, USB, RS232

Software: Supports NC CAM Suite TPAED132

Safety and enclosure:

Full perimeter safety cabin

Automatic synchronized front safety door

Polycarbonate panels and safety interlocks

Power and standards:

Supply voltage: 400 V / 50 Hz

CE safety compliance

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing