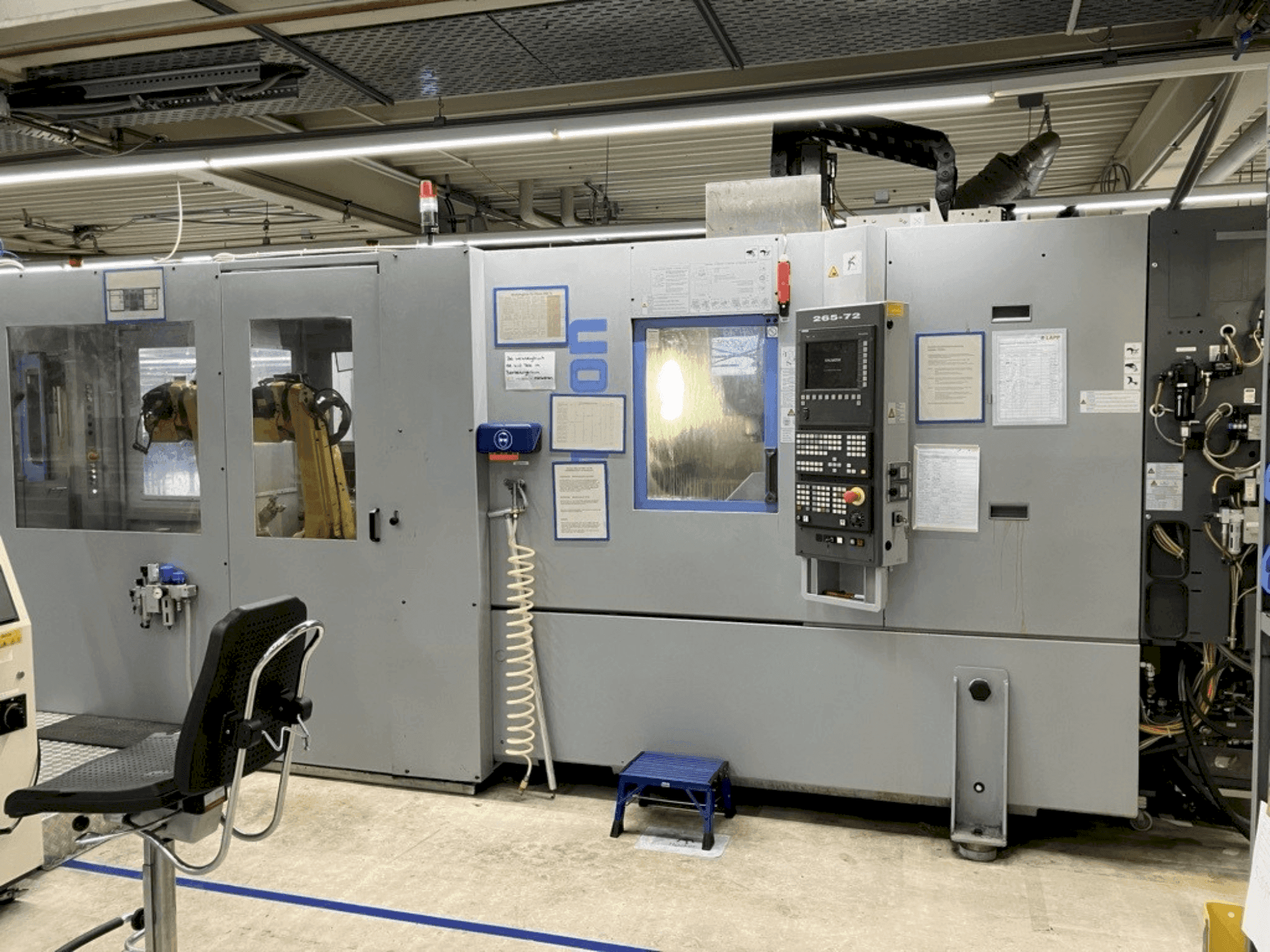

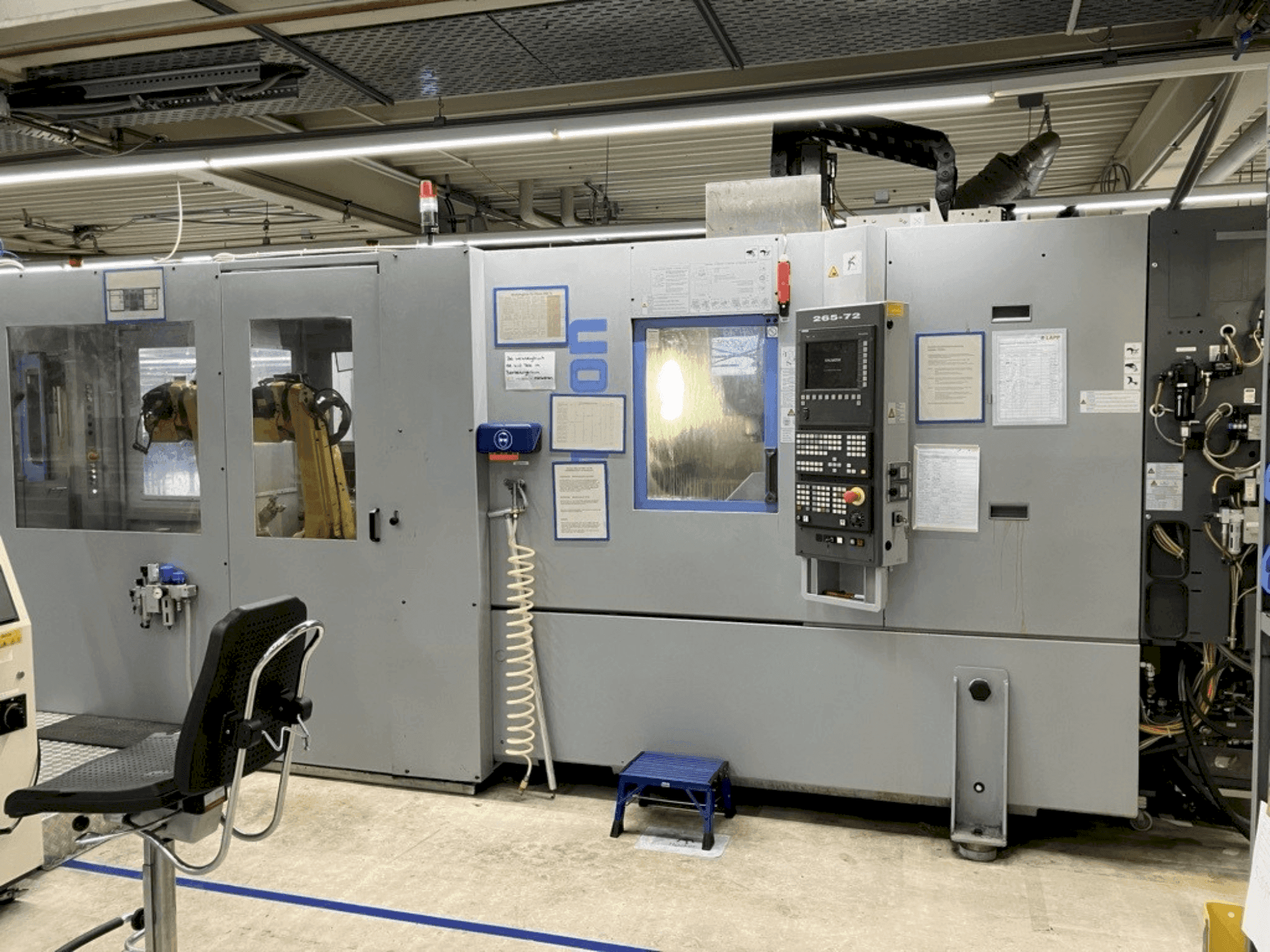

CHIRON - FZ 12 KWDE-MIL-CHI-2012-00002

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used CHIRON FZ 12 KW For Sale | gindumac.com

This 3-axis CHIRON FZ 12 KW vertical machining center was manufactured in 2012. It features a high-speed spindle with a maximum speed of 12,000 rpm and a rapid traverse speed of up to 60 m/min on the Z-axis. The machine includes a 24-slot automatic tool changer and can handle a table load of up to 500 kg. Ideal for precision machining tasks. Contact us for more information about this machine.

Overview

- brand: CHIRON

- year: 2012

- MODEL: FZ 12 KW

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

Technical Information - CHIRON FZ 12 KW

Dimensions

- Table Load: 500 kg

Movement

- Number of Axes: 3

- X-axis Travel: 550 mm

- Y-axis Travel: 320 mm

- Z-axis Travel: 360 mm

Technical Specification

- Max. Tool Weight: 5 kg

- Spindle Speed: 12000 RPM

Additional Information

Machine Benefits

Technical Machine Benefits

- Controlled axes: 6 axes

- Reach: 704 mm

- Acceleration/deceleration: 0 to 12000 min-1 in 0. 6 seconds

- Clamping surface: 820 x 440 mm²

- Drilling capacity in st 60: Ø 16 mm

- Tapping: m 16

- Milling capacity in st 60: 80 cm³/min

- Acceleration: x & y axis 0. 7 g, z axis 1. 0 g

Extra Information

Movement Axis Movement Range and Speed: J1: 340°/360° (option) at 350°/s J2: 200° at 350°/s J3: 388° at 400°/s J4: 380° at 450°/s J5: 240° at 450°/s J6: 720° at 720°/s Allowable Load Moment: J4 & J5: 11.9 Nm J6: 6.7 Nm Repeatability: +/- 0.02 mm Maximum Speed J1: 195°/s J2: 175°/s J3: 180°/s J4 & J5: 400°/s J6: 600°/s Allowable Load Moment J4 & J5: 7.7 Nm J6: 9.8 Nm Tools Automatic Tool Changer: Tool Pockets: 24 Tool Change Time: approx. 0.9 s Chip-to-Chip Time: approx. 2.4 s The workpieces are supplied via an automated feeding system and sequentially loaded into the Chiron machining centres by two Fanuc industrial robots. Once the machining processes are complete, they are removed again. The robots then transfer the components to a transfer system, which transports them to the downstream cleaning system. The integrated washing line ensures reliable cleaning of the components in accordance with the defined cleanliness specifications. After the washing process, two synchronously operating Fanuc robots take over the cleaned parts in the rear section of the system. Depending on the process specifications, these are either palletised automatically or further processed in a downstream step, for example by riveting. The entire system operates fully automatically.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing