Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

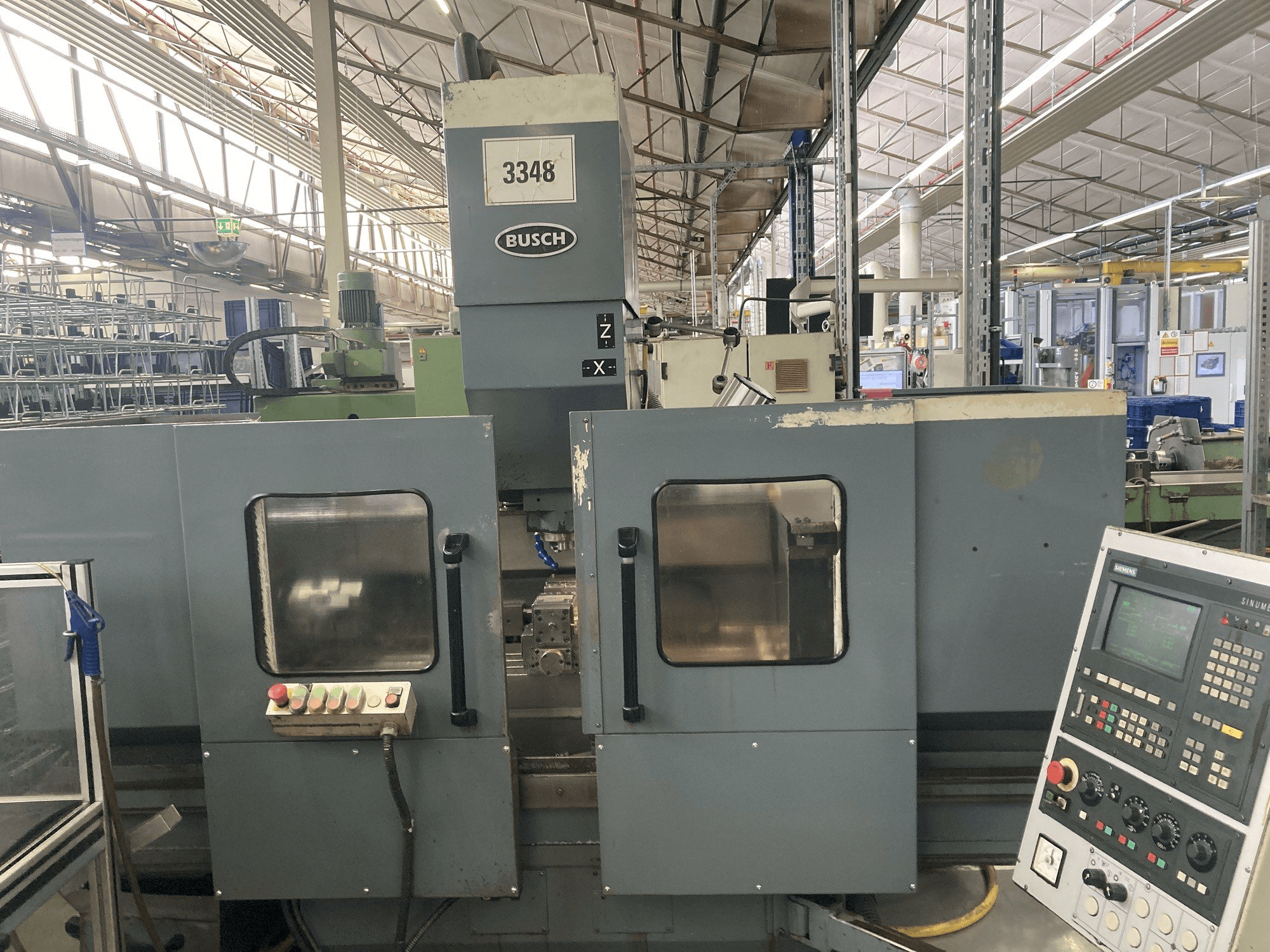

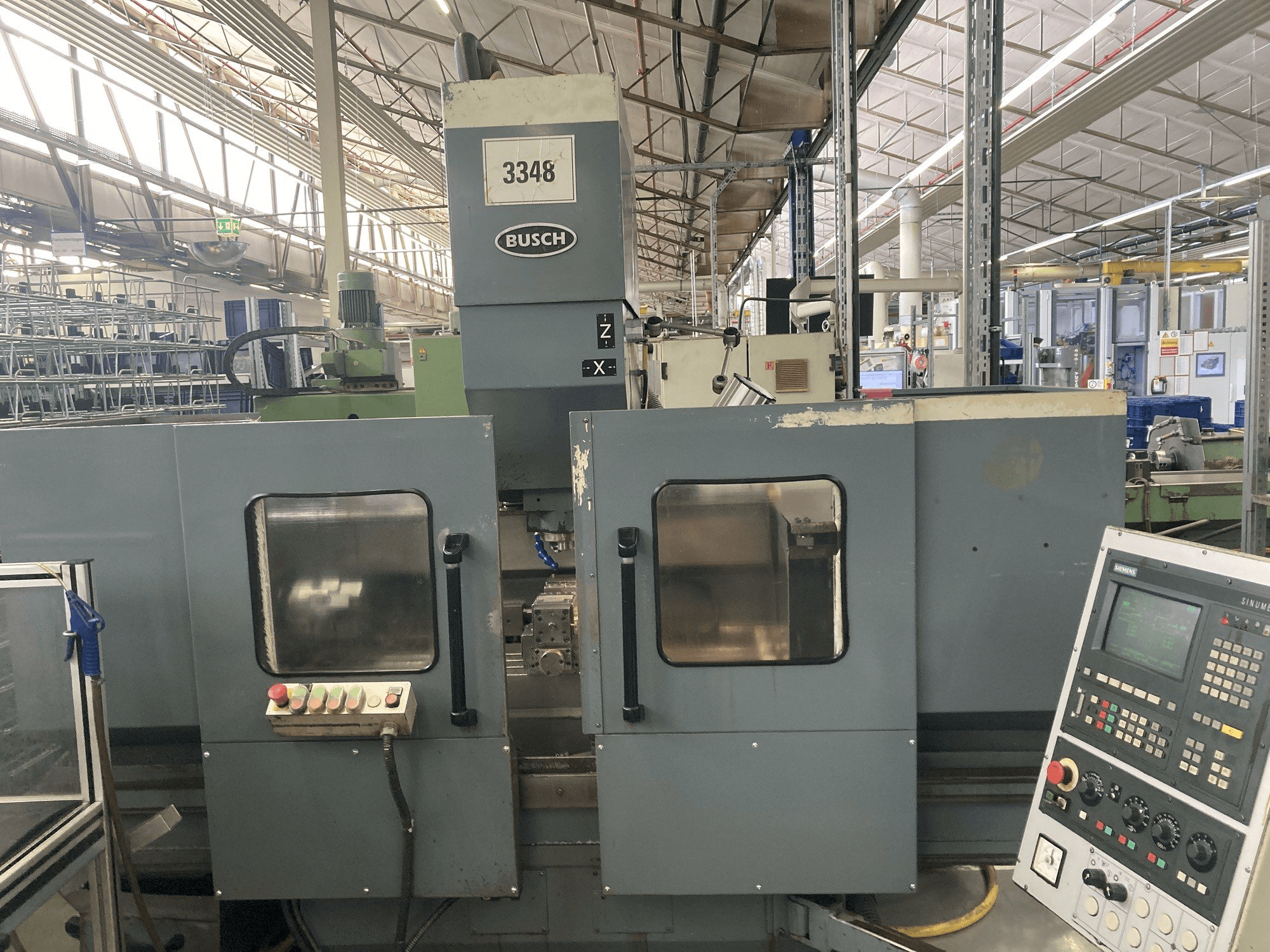

BUSCH - FB 1- 150DE-SHE-BUS-1992-00001

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Machine Tools

- ➤ Used BUSCH FB 1- 150 For Sale | gindumac.com

This 4-axis BUSCH FB 1-150 milling machine was manufactured in 1992. It features a robust machine bed with diagonally ribbed welded construction, ensuring stability and low vibration. Equipped with a Siemens SINUMERIK 810M control panel, it offers precise CNC path control. The spindle supports speeds from 40 to 6,000 rpm, enhancing its versatility. Ideal for complex milling tasks, the machine includes a CNC dividing head and a circular tool magazine. Reach out for further details regarding this milling machine.

Overview

- brand: BUSCH

- year: 1992

- MODEL: FB 1- 150

- application type: Milling

- Location: Germany

- machine type: Vertical Machining Centre

- control unit brand: SIEMENS

Technical Information - BUSCH FB 1- 150

Control Unit

- Control Brand: SIEMENS

- Control Model: SINUMERIK 810M

Movement

- X-axis Travel: 1000 mm

- Y-axis Travel: 150 mm

- Z-axis Travel: 200 mm

Technical Specification

- Spindle Speed: 6000 RPM

Additional Information

Additional equipment

- Machine with 2 hydraulic vices

- 4th axis

- Tailstock

- Machine bed with guides for the X-axis and a mounting surface for the table plate 1300 x 300 mm with 3 T-slots

- PTFE-based sliding linings on hardened steel guide rails

- Coolant system for external coolant supply on the headstock

- Large-capacity coolant tank

- Separate pumps for coolant and flushing agent flow

- Control cabinet bolted to the rear of the machine

- Circular tool magazine for 8 tools in the pick-up system

Machine Benefits

Qualitative Machine Benefits

- Machine bed in rigid, continuously diagonally ribbed welded construction

- Indirect position measuring system by means of rotary encoder on the spindle

- Headstock with six bearings and high rigidity

- Tool clamping by means of collets with disc springs

Technical Machine Benefits

- Cnc dividing head integrated as fourth axis for face and spiral curve milling work

- Two automatic clamping devices (vices and centre clamping device via m function)

- High rigidity and low vibration due to torsion-resistant and diagonally ribbed welded constructions

- High dynamics main drive by three-phase servo motor

Extra Information

Machine still under power

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing