Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

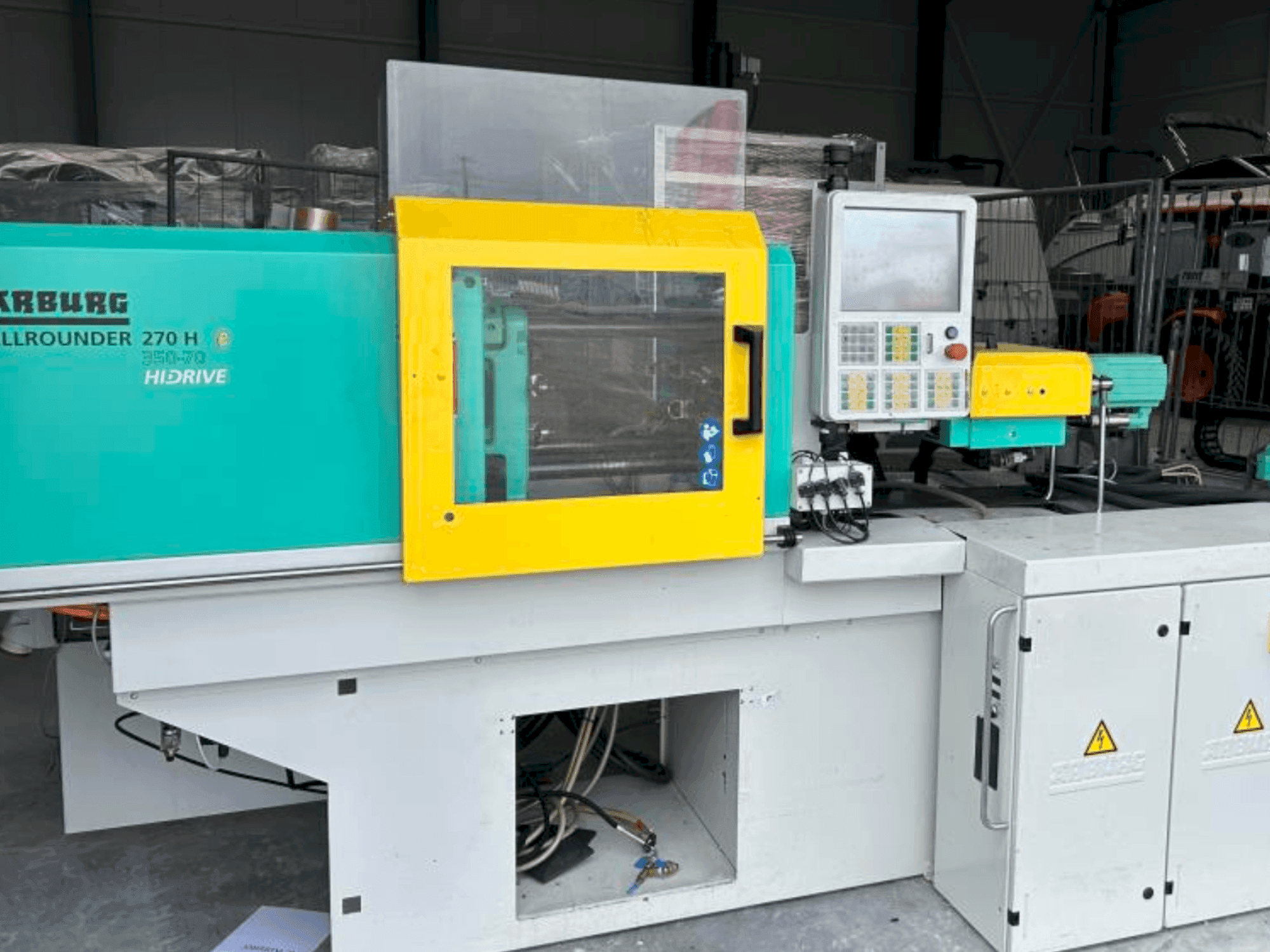

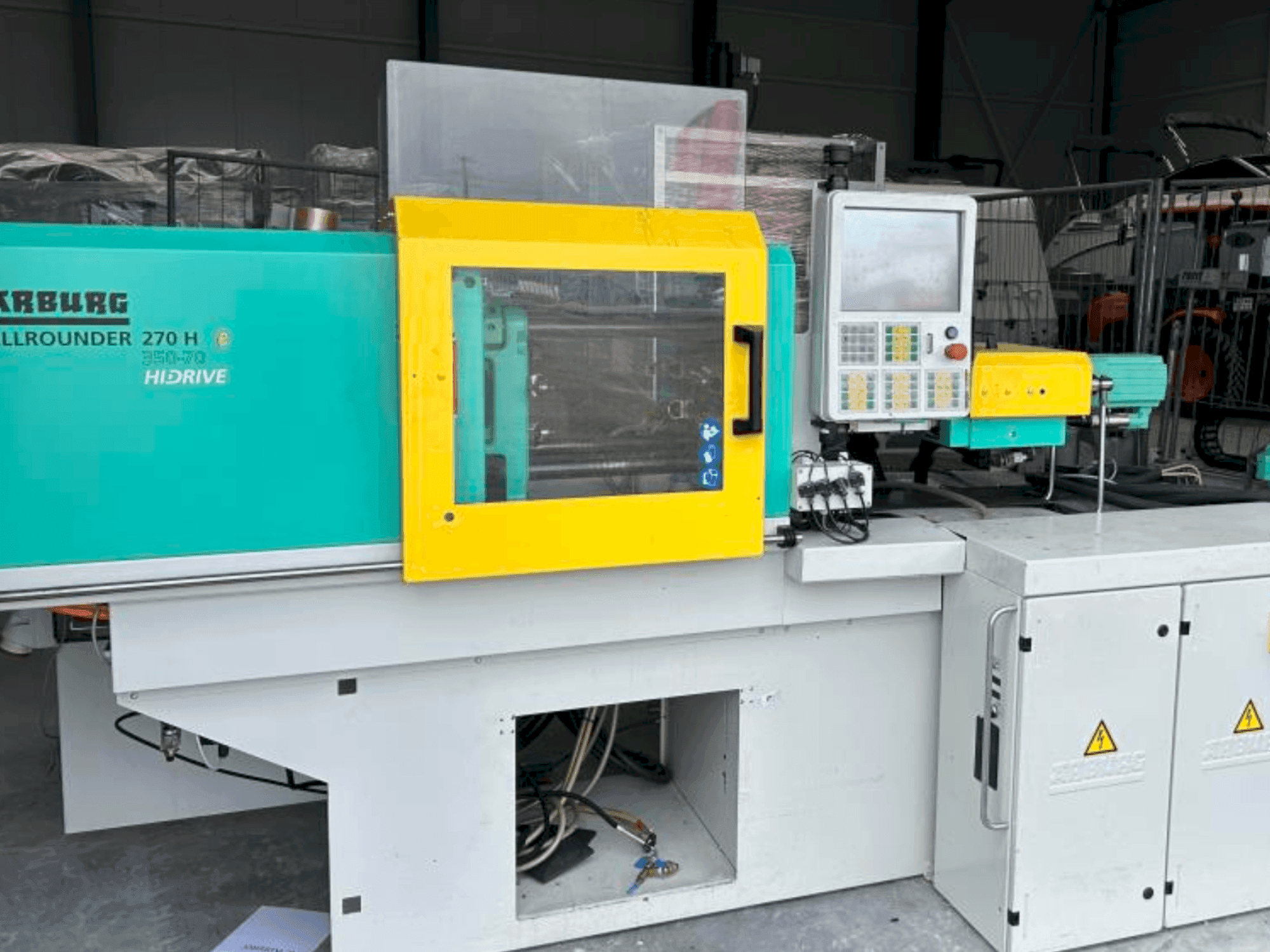

Arburg - Allrounder 270 H 350-70DE-INJ-ARB-2011-00010

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Arburg Allrounder 270 H 350-70 | Injection Moulding

This Arburg Allrounder 270 H 350-70 was manufactured in 2013. It features a screw diameter of 30 mm, a maximum injection pressure of 2000 bar, and a nozzle lift-off stroke of 210 mm. With 20,000 operating hours, this hydraulic injection moulding machine includes machine handling. Consider the opportunity to buy this Arburg Allrounder 270 H 350-70 hydraulic injection moulding machine. Contact us for more information.

Overview

- brand: Arburg

- year: 2013

- MODEL: Allrounder 270 H 350-70

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - Arburg Allrounder 270 H 350-70

Technical Specification

- Screw Diameter: 30 mm

Additional Information

Additional equipment

- Machine handling is included.

Machine Benefits

Technical Machine Benefits

- Operating voltage: 400 v

- Control voltage: 230 v

- Total rated current: 70 a

- Total connected load: 43 kw

- Screw torque: 250 nm

- Injection flow: 312 bar

- Nozzle lift-off stroke: 210 mm

- Nozzle contact force: 50 kn

Extra Information

EUROMAP size specification 350-70/ Clamping unit: Clamping force 350 kN/ Mold retention force 0.5-40 kN/ Opening stroke 200 mm/ Mold installation height 150-350 mm/ Distance between clamping platens 350-550 mm/ Inter-tie bar spacing 270 x 270 mm/ Mold clamping platens (w x h) 380 x 380 mm/ Weight of moving tool half 200 kg/ Ejector force 16 kN/ Ejector stroke 60 mm/ Hydraulics, drive, other: Hydraulic pump drive power 3 kW/ Dry run time during opening stroke" Total installed power 0.7-189 s-mm/ Control cabinet: Safety regulations DIN EN 60204/ Socket combination (1 Schuko, 1 Cekon) 1x16 A/ Injection unit: Screw diameter 18 mm/ Effective screw length 24.5 L/D/ Screw travel 90 mm/ Calculated stroke 23 cm/ Shot weight 21 g PS/ Material throughput 4.1 kg/h/ Injection pressure 2500 bar/ Injection flow with accumulator 138 cm/ Back pressure positive/negative 350 bar/ Screw circumferential speed 49 m/min/ Screw torque 90 Nm/ Nozzle contact force 50 kN/ Nozzle lift-off stroke 150 mm/ Installed cylinder heating power / heating zones 3.75 kW/ Installed nozzle heating power 0.3 kW/ Granule hopper capacity 25 l/ Dimensions and weights of the base machine: Oil tank 115 l/ Net weight 2300 kg/ Electrical connection (pre-fuse) motor 50 A

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing