Thank you for your visit

This machine was recently sold. Take a look at similar options or get in touch with us directly.

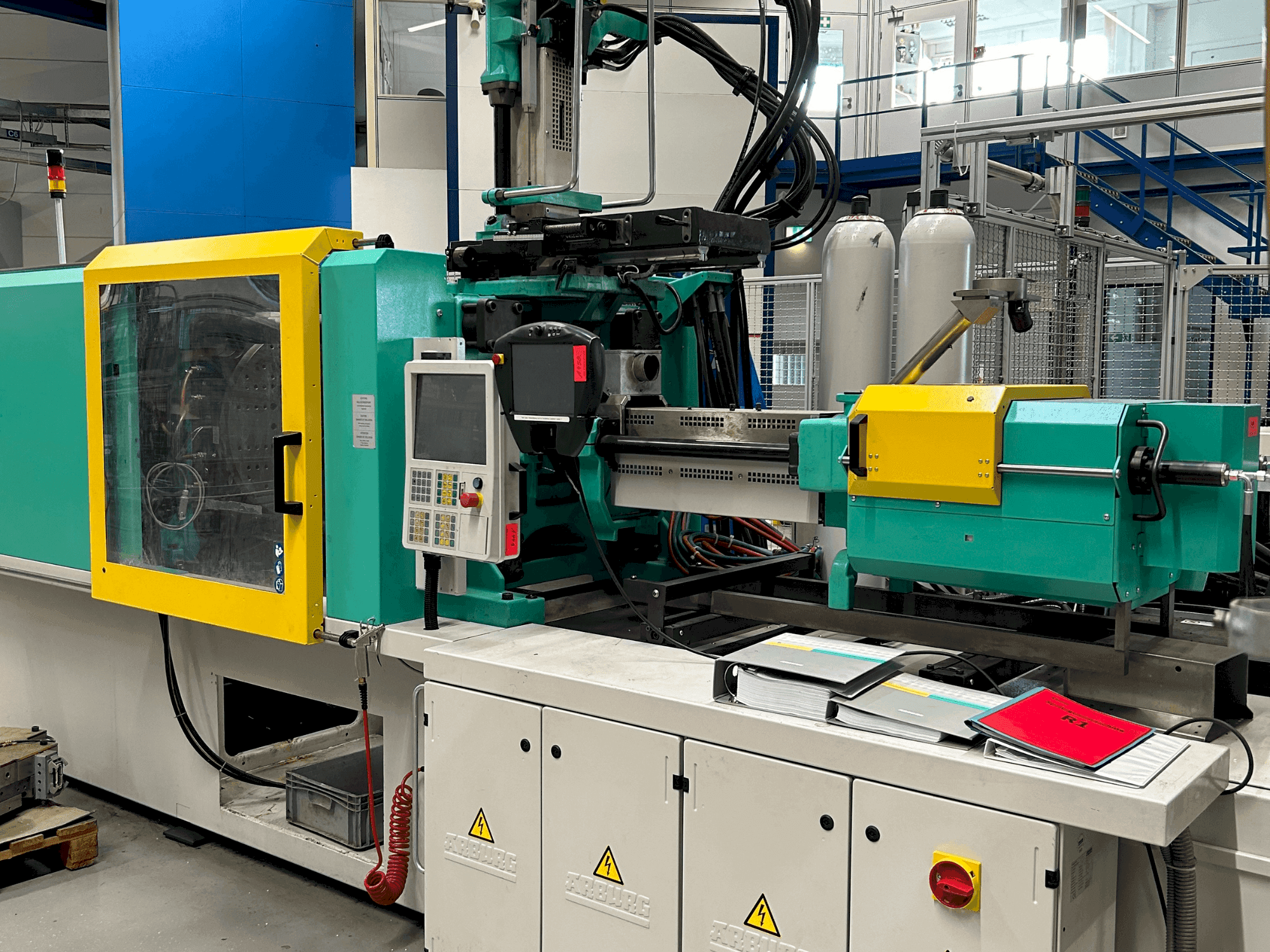

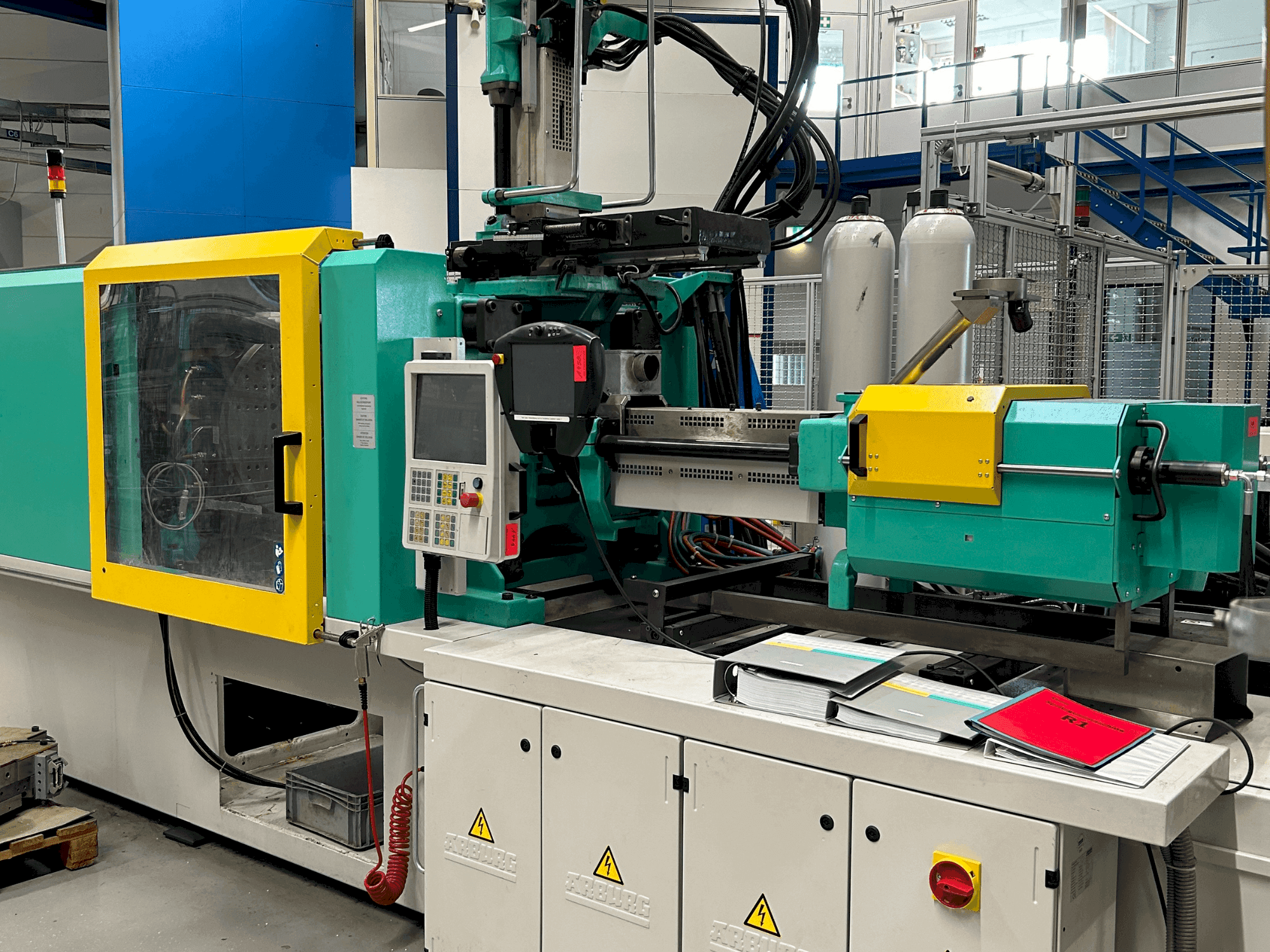

Arburg - 570S 2200-400/170DE-INJ-ARB-2016-00003

Do you have further questions? Contact us.

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Products

- Plastics Processing Machinery

- ➤ Used Arburg 570S 2200-400/170 For Sale | gindumac.com

This Arburg 570S 2200-400/170 was manufactured in 2016. It features a clamping force of 2,200 kN and a hydraulic accumulator for high-speed operations. Equipped with a 45 kW drive motor and a pressure accumulator module with a 230 bar maximum working pressure. The machine includes a high-performance cooler and a central injection position. Consider the opportunity to buy this Arburg 570S 2200-400/170 hydraulic injection moulding machine. Contact us for more information.

Overview

- brand: Arburg

- year: 2016

- MODEL: 570S 2200-400/170

- application type: Injection Moulding

- Location: Germany

- machine type: Hydraulic Injection Moulding Machine

Technical Information - Arburg 570S 2200-400/170

Technical Specification

- Clamping Force: 2200 kN

Additional Information

Machine Benefits

Technical Machine Benefits

- Modular, multiprocessor graphic selogica control system.

- Enhanced "extended monitoring," "extended motions," "production control," "optimization/operating aids," "quality assurance," and "documentation" packages.

- Drive unit with a 45 kw drive motor and pump combination.

- Pressure accumulator module with a maximum working pressure of 230 bar and a storage volume of 100 liters.

- Continuous oil circulation with an additional pump for increased cooling capacity.

- Hydraulic accumulator technology for high speeds.

- Injection pressure increased by approximately 10% (to a maximum of 2500 bar).

- Position-controlled screw with control valve on the injection unit.

- Safety guard open at the top with injection simultaneously during mold closing.

Extra Information

Clamping Force Clamping force of 2200 kN. Clamping platen set with a central injection position and a centering diameter of 125 mm. Increased minimum tool installation height to 450 mm. Plus kit to enlarge the clamping surface. Machine-specific cooling circuits with programmable control and valve management for enhanced efficiency and precision. Tools Ejector quick-release coupling. Controlled hydraulic ejector on the movable mold plate. Multiple blow-out units with 3/2-way valves. Limit switch connection for core pull control. Media Two additional circuits for tool temperature control. Pneumatic maintenance unit with 2 pressure reducers. Several controlled cooling circuits with heat management capabilities. Extra Information Increased power of heating control circuits to 3.6 kW (230 V), 16 amps per heating circuit. Acoustic fault indication with centralized placement for ease of monitoring.

*There may be differences between the data shown and the actual values, this should be confirmed by the sales representative.

Borja Garcia

Payment Terms

Payment in advance

Asset Financing

Products related to Arburg 570S 2200-400/170

CJ480M3V

CHENDE - Hydraulic Injection Moulding Machine

Systec 160-520/430

DEMAG - Hydraulic Injection Moulding Machine

SYNERGY 1500-600

Netstal - Hydraulic Injection Moulding Machine

Allrounder 920H 5000-4600

Arburg - Hydraulic Injection Moulding Machine

Victory 750/200 Tech

Engel - Hydraulic Injection Moulding Machine

S 6000-5500E

Netstal - Hydraulic Injection Moulding Machine

Allrounder 520S-1600-400

Arburg - Hydraulic Injection Moulding Machine

VM 150/750V R1520 UNIGLOG B6S

Battenfeld - Hydraulic Injection Moulding Machine

ROBOSHOT S 100 iA

FANUC - Electrical Injection Moulding Machine

Roboshot S150iA

FANUC - Electrical Injection Moulding Machine

ELEKTRA 180

FERROMATIK - Electrical Injection Moulding Machine

El-Exis S 250/630-1450

SUMITOMO SHI DEMAG - Hydraulic Injection Moulding Machine